Dec . 25, 2024 23:15 Back to list

6618 titanium dioxide manufacturer

The Role of 6618 Titanium Dioxide Manufacturers in the Global Market

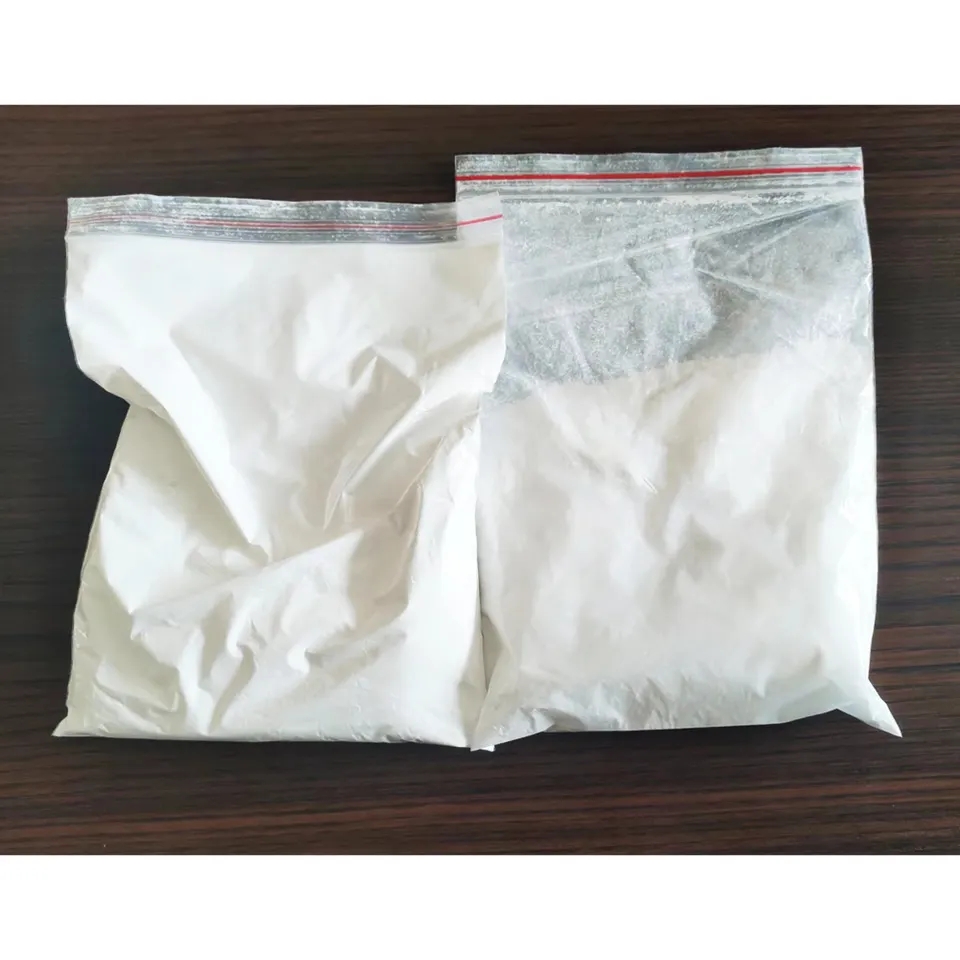

Titanium dioxide (TiO2) has become an indispensable material across various industries, renowned for its exceptional properties such as high opacity, brightness, and UV resistance. Among the myriad of titanium dioxide grades available, 6618 titanium dioxide stands out due to its unique characteristics and applications. This article explores the significance of 6618 titanium dioxide manufacturers, highlighting their roles, production processes, and the impacts they have on global markets.

Understanding 6618 Titanium Dioxide

Before delving into the manufacturing aspects, it is essential to understand what 6618 titanium dioxide is. This grade is often utilized in the production of coatings, plastics, and paper due to its excellent light-scattering properties. The 6618 designation indicates a specific formulation or treatment that enhances its performance in certain applications. Manufacturers who specialize in 6618 titanium dioxide adhere to stringent quality control measures to ensure that their products meet international standards.

The Manufacturing Process

The process of manufacturing titanium dioxide generally includes two principal methods the sulfate process and the chloride process. Both methods have their advantages and disadvantages, but for 6618 grade production, the chloride process is often preferred. This method involves oxidizing titanium tetrachloride to produce TiO2, which can then be further treated to enhance specific properties desired in the end product.

Manufacturers invest significantly in their production facilities, employing advanced technologies to ensure high purity and optimal particle size distribution of titanium dioxide. Quality control is paramount, as any impurities can adversely affect the material's characteristics and its performance in end-use applications. As such, reputable 6618 titanium dioxide manufacturers implement extensive testing and validation processes throughout production.

Market Trends and Demand

6618 titanium dioxide manufacturer

The global demand for titanium dioxide, particularly 6618 grade, has seen significant growth over the last decade. The rise of industries such as automotive, construction, and consumer goods has driven this demand. For instance, in the paint and coatings sector, the need for high-performance, durable products has led to an increased reliance on high-quality titanium dioxide to achieve superior opacity and durability.

Moreover, environmental concerns have propelled the shift towards sustainable practices within the titanium dioxide industry. Manufacturers are now focusing on producing eco-friendly formulations and adopting greener production methods. This trend aligns with global sustainability goals and appeals to environmentally conscious consumers.

Challenges Faced by Manufacturers

Despite the robust growth in demand, 6618 titanium dioxide manufacturers face several challenges. One of the most pressing issues is the fluctuating cost of raw materials. The price of titanium feedstock can be volatile, impacting production costs and, consequently, pricing strategies. Additionally, manufacturers must navigate strict environmental regulations, particularly in regions like Europe and North America, where compliance entails significant investment in cleaner technologies.

Another challenge lies in competition. The market is flooded with various suppliers, making it imperative for manufacturers to differentiate their products through innovation and quality. Continuous research and development play a pivotal role in this aspect, enabling manufacturers to create specialized grades of titanium dioxide that cater to niche markets.

The Future of 6618 Titanium Dioxide Manufacturing

As industries continue to evolve, the future of 6618 titanium dioxide manufacturing looks promising. The increasing emphasis on high-performance materials and sustainable practices is likely to drive further innovations in production techniques and applications. Additionally, advancements in nanotechnology hold the potential to enhance the performance of titanium dioxide even further, opening doors to new and exciting applications.

In conclusion, 6618 titanium dioxide manufacturers are crucial players in the global market, contributing to various industries and driving advancements in material science. Their commitment to quality, innovation, and sustainability will significantly shape the future landscape of this essential material. With ongoing research and development efforts, the potential of titanium dioxide, particularly the 6618 grade, remains vast and filled with opportunities.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025