Nov . 06, 2024 03:32 Back to list

Quotes for 30-50nm TiO2 Powder Manufacturers and Suppliers in the Industry

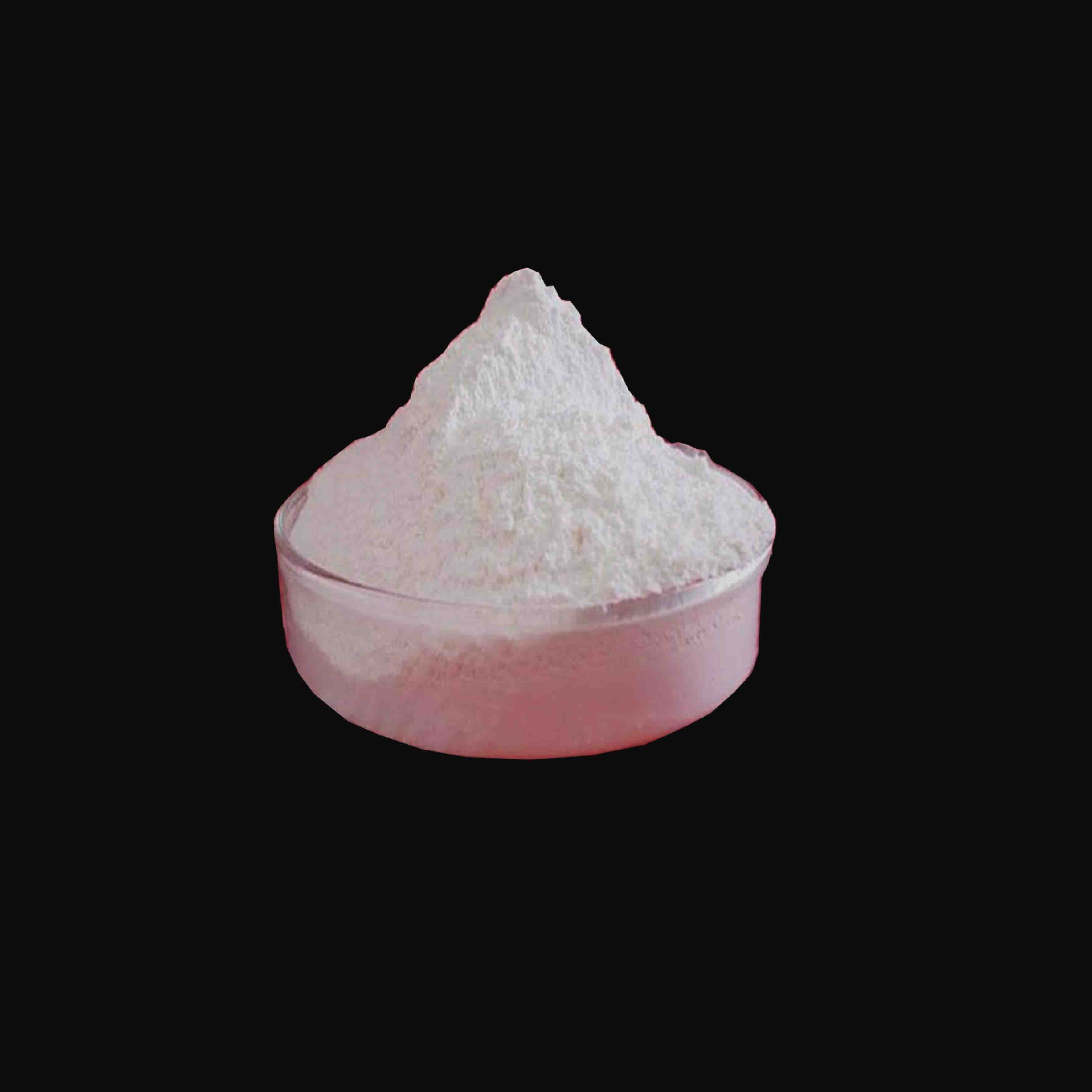

The Growing Importance of 30-50nm TiO2 Powders in Various Industries

Titanium dioxide (TiO2) has garnered significant attention across multiple sectors due to its unique properties, including high refractive index, photocatalytic ability, and non-toxic characteristics. Among the various forms of TiO2, nanoscale powders in the range of 30-50 nanometers have emerged as particularly valuable for diverse applications. This article explores the myriad uses of 30-50nm TiO2 powders, their production processes, and the industry's perspective from factories that specialize in producing these advanced materials.

Unique Properties and Advantages

TiO2 nanoparticles in the size range of 30-50nm display exceptional photocatalytic activity, which can be exceptionally beneficial in environmental applications. This size range allows for a high surface area to volume ratio, enhancing the material's reactivity and making it suitable for applications in air and water purification. Additionally, these nanoparticles exhibit excellent UV-blocking properties, making them ideal for use in sunscreens and cosmetic products.

Besides environmental applications, 30-50nm TiO2 powders are gaining traction in the coating industry. Their ability to enhance durability, adhesion, and corrosion resistance makes them excellent additives in paints, varnishes, and inks. When incorporated into coatings, these nanoparticles can improve the longevity of surfaces exposed to environmental stressors.

Production Techniques

The production of 30-50nm TiO2 powders involves intricate processes aimed at achieving uniform particle size and high purity. Common techniques include sol-gel synthesis, hydrothermal methods, and chemical vapor deposition (CVD). Each method has its advantages and can be customized based on the intended application of the TiO2 powders.

1. Sol-Gel Synthesis This method involves converting a solution into a solid gel phase, and it is particularly valuable for producing high-purity nanoparticles. The sol-gel process allows for precise control over the chemical composition and size of the final product.

2. Hydrothermal Methods In this process, titanium precursors are subjected to high pressures and temperatures in an aqueous solution, yielding TiO2 nanoparticles with desired sizes. This method can produce highly crystalline particles that enhance the photocatalytic efficacy.

3. Chemical Vapor Deposition (CVD) CVD allows for the deposition of TiO2 thin films and nanoparticles on various substrates. The process is characterized by its ability to create uniform coatings, making it favorable for application in electronics and semiconductors.

30-50nm tio2 powders quotes factories

Market Dynamics and Factory Insights

As demand for 30-50nm TiO2 powders rises, several factories have come to dominate the market. These factories emphasize the importance of quality control, ensuring that the produced nanoparticles meet stringent standards for purity, size distribution, and functionality. Many manufacturers engage in extensive research and development, striving for innovations in production techniques and exploring new applications for their products.

A growing trend among factories is the shift towards environmentally friendly production practices. Many producers are incorporating sustainable materials and processes to minimize environmental impact. This shift not only aligns with global sustainability goals but also appeals to consumers increasingly concerned about the ecological footprint of the products they use.

Applications Across Industries

The applications of 30-50nm TiO2 powders extend across various fields

- Cosmetics In sunscreens and skincare products, TiO2 serves as a physical blocker of UV rays, providing broad-spectrum sun protection. - Environmental Remediation TiO2 nanoparticles are used in photocatalytic applications for the breakdown of pollutants, making them valuable for air and water purification technologies.

- Construction The addition of TiO2 to building materials can enhance self-cleaning properties and improve durability against harsh weather conditions.

- Electronics In the electronics industry, TiO2 is used for its dielectric properties in capacitors and other electronic components.

Conclusion

The increasing demand for 30-50nm TiO2 powders showcases their significance across various applications, from environmental technologies to cosmetics and coatings. With advancements in production techniques and a commitment to sustainable practices, factories producing these materials are well-positioned to meet the challenges and opportunities of a rapidly evolving market. As research continues to unveil new applications and enhance existing ones, the future of 30-50nm TiO2 powders looks exceptionally promising.

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025