Dec . 25, 2024 10:46 Back to list

13463-67-7 titanium dioxide factories

The Significance of Titanium Dioxide Factories

Titanium dioxide, known by its chemical formula TiO2, is a widely utilized compound that serves as a pigment, ultraviolet (UV) light blocker, and a substance in various applications ranging from coatings to cosmetics. The synthesis of titanium dioxide is pivotal in numerous industries, and understanding the factories involved in its production is crucial for grasping its market dynamics and environmental impact.

Manufacturing Process of Titanium Dioxide

The production of titanium dioxide primarily occurs through two processes the sulfate process and the chloride process. The sulfate process involves the reaction of titanium-bearing ores, such as ilmenite, with sulfuric acid. This method generates a titanium sulfate solution, which is then hydrolyzed to produce titanium dioxide. Conversely, the chloride process starts by converting titanium-bearing ores into titanium tetrachloride through chlorine gas and high temperatures. The resultant titanium tetrachloride is then oxidized to yield titanium dioxide. Each method has distinct advantages and drawbacks, thereby impacting production costs and environmental emissions.

Global Production and Factories

The global demand for titanium dioxide has prompted numerous factories to invest in its production. Key players in this industry are located in various regions, including North America, Europe, and Asia. For instance, companies like Chemours, Tronox, and Huntsman are among the largest producers, each operating multiple facilities that leverage different production techniques. The locations of these factories are strategically chosen based on proximity to raw materials and market demand.

In recent years, the production of titanium dioxide has been subject to increased regulatory scrutiny. Factories must comply with strict environmental standards aimed at minimizing the ecological footprint of their operations. This has prompted many manufacturers to adopt greener technologies, reducing waste and emissions during production. The push for sustainability has led to innovations in the manufacturing processes, resulting in a more efficient and environmentally friendly production of titanium dioxide.

13463-67-7 titanium dioxide factories

Market Applications

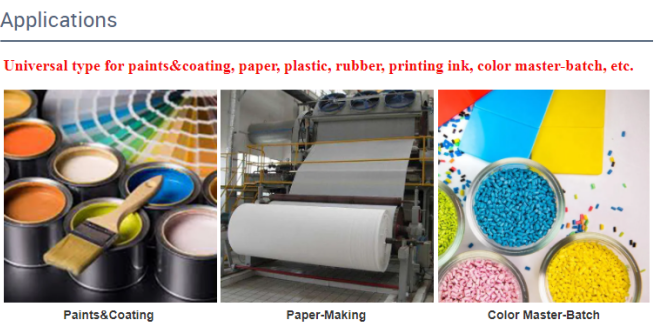

Titanium dioxide is a versatile compound with a wide range of applications. Its primary use is as a white pigment in paints, coatings, and plastics due to its brightness and opacity. The extensive use of TiO2 in the coatings industry has positioned it as a staple ingredient, as it enhances the durability and UV resistance of paints. Additionally, the cosmetic industry employs titanium dioxide in products like sunscreens and makeup due to its excellent UV-blocking properties. It also plays a vital role in the manufacture of paper, food additives, and pharmaceuticals.

Economic Impact

The titanium dioxide market significantly contributes to the economy, particularly in regions where manufacturing facilities are located. It creates numerous job opportunities, from production to research and development. Moreover, as demand for titanium dioxide grows in emerging markets like Asia and Africa, factories are likely to expand their operations, contributing to economic growth in those regions.

However, market dynamics can be influenced by fluctuating raw material prices and changes in regulations that affect production costs. The increasing emphasis on sustainability and environmental responsibility is pushing factories to adapt, which may lead to higher production costs in the short term. Nevertheless, these shifts are essential for long-term viability in an increasingly eco-conscious market.

Conclusion

The factories producing titanium dioxide play a crucial role in meeting the demands of a wide array of industries. As the market continues to evolve, driven by consumer preferences for sustainability and innovation, it is imperative for manufacturers to adopt environmentally friendly practices. Understanding the complexities of titanium dioxide production reveals not only its economic importance but also the challenges faced in aligning industrial practices with environmental sustainability. Looking ahead, the adaptation of production technologies and practices will likely shape the future of titanium dioxide manufacturing, ensuring its continued relevance across various sectors.

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025