Nov . 10, 2025 00:35 Back to list

13463-67-7 tio2 using for coating | High-Purity Anatase

13463-67-7 Tio2 Using For Coating is a key solution in the chemical industry industry, specifically within Pigment manufacturing and Titanium dioxide manufacturing. This article explores how Hebei Caiqing New Material Technology Co., LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- 13463-67-7 Tio2 Using For Coating Overview

- Benefits & Use Cases of 13463-67-7 Tio2 Using For Coating in Titanium dioxide manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in chemical industry

- Conclusion on 13463-67-7 Tio2 Using For Coating from Hebei Caiqing New Material Technology Co., LTD

13463-67-7 Tio2 Using For Coating Overview

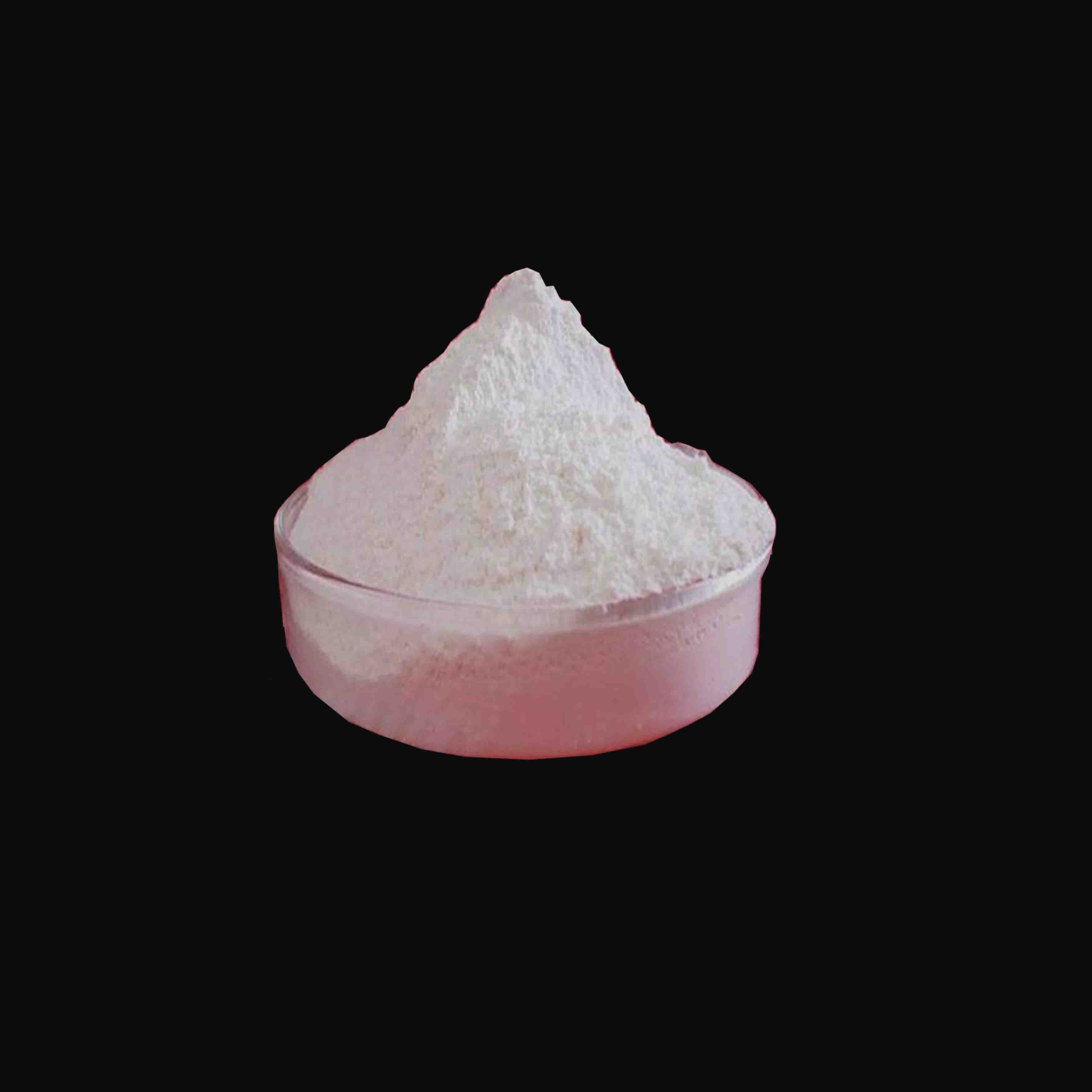

CAS 13463-67-7 refers to titanium dioxide (TiO2), the most widely used white pigment in coatings due to its unparalleled refractive index (~2.7), opacity, and brightness. As a coating material TiO2, it delivers hiding power, clean undertone, and UV screening across architectural, industrial, and specialty systems. Both rutile and anatase type titanium dioxide are used: rutile for superior weatherability and gloss retention; anatase grade titanium dioxide for high brightness and controlled matte in interior emulsions, paper, and inks. In practical terms, 13463-67-7 Tio2 Using For Coating supports stable dispersion, consistent particle size distribution, and strong tinting strength demanded by B2B buyers.

Hebei Caiqing New Material Technology Co., LTD—a trusted China titanium dioxide company—supplies dioxide titanium CAS 13463-67-7 with dependable quality and supply assurance. As a china factory supply titanium dioxide partner, Hebei Caiqing serves paint makers, coil coaters, powder coating producers, and ink formulators that require reliable whiteness, low impurities, and surface-treated rutile for outdoor durability. Whether you specify anatase type TiO2 for interior brightness or a robust rutile grade for exterior resistance, Hebei Caiqing aligns grade selection, packaging, and logistics to your production requirements.

Benefits & Use Cases of 13463-67-7 Tio2 Using For Coating in Titanium dioxide manufacturing

In paint and coatings production, 13463-67-7 Tio2 Using For Coating is integral from grind to let-down. In architectural emulsions, rutile grades enable high PVC systems to achieve class-leading opacity and scrub resistance. For industrial maintenance and marine, surface-treated rutile offers UV stability and chalking resistance that extends service life in harsh environments. Powder coatings benefit from whiteness, coverage at low film builds, and charge stability, while coil and can coatings rely on consistent particle size to maintain gloss and smoothness. For inks and paper coatings, anatase type TiO2 can deliver high brightness and a neutral undertone ideal for color fidelity.

Hebei Caiqing New Material Technology Co., LTD—an experienced china TiO2 powder company—focuses on dispersion performance, controlled surface treatment, and low volatile content to streamline your milling and batching processes. Competitive advantages include strong hiding power, reliable whiteness index, and compatibility across acrylic, epoxy, polyurethane, polyester, and alkyd systems. With dye pigment titanium dioxide options tailored to end-use, formulators can optimize gloss, rheology, and opacity while reducing the risk of flocculation or flood-and-float during tinting.

Cost, Maintenance & User Experience

Total cost of ownership for 13463-67-7 Tio2 Using For Coating extends beyond price-per-ton. High-quality rutile TiO2 can lower dosage for equal hiding, shorten dispersion time, and reduce rework—improving batch acceptance rates and throughput. Stable quality minimizes color drift between lots, streamlines QC, and reduces machine downtime. Lower abrasiveness can also help limit bead-mill wear. Many B2B buyers report smoother let-down, faster tint development, and consistent opacity across both solventborne and waterborne platforms when partnering with a dependable supplier.

Hebei Caiqing supports packaging in 25 kg bags and big bags, with guidance on storage to maintain free-flowing powder and stable performance. Clear technical data and responsive supply help reduce inventory buffers and working capital. For procurement teams, the ROI is realized in predictable batch costs, simpler scale-up, and fewer customer complaints over long-term field performance. In short, a reliable china titanium dioxide company improves both operational efficiency and product reputation in the market.

Sustainability & Market Trends in chemical industry

Coatings markets are increasingly shaped by regulations and sustainability targets. Waterborne, low-VOC, and high-solids technologies depend on pigments that disperse efficiently and maintain film integrity. TiO2—CAS 13463-67-7—supports lifecycle performance by delivering opacity at lower film builds, enabling formulators to reduce binder demand and resource intensity per square meter coated. Global compliance expectations (such as REACH-registered inputs and restricted substance controls) are now standard gating criteria for multinational buyers and specifiers.

Hebei Caiqing New Material Technology Co., LTD positions itself as a forward-looking partner, helping customers navigate eco-label requirements, regional regulations, and supply chain transparency. As a china factory supply titanium dioxide producer, the company emphasizes consistent quality, technical support, and documentation that simplify audits and approvals. Whether your focus is architectural EPDs, industrial durability, or circular packaging, Hebei Caiqing works with procurement, R&D, and sustainability teams to align TiO2 selection with performance and environmental goals.

Conclusion on 13463-67-7 Tio2 Using For Coating from Hebei Caiqing New Material Technology Co., LTD

For B2B decision makers in chemical industry / Pigment manufacturing / Titanium dioxide manufacturing, 13463-67-7 Tio2 Using For Coating remains essential for opacity, color fidelity, and long-term film performance. Hebei Caiqing New Material Technology Co., LTD combines dependable supply with technical support across rutile and anatase grades—making it a trusted source for consistent, high-value titanium dioxide. Explore grades suited to architectural, industrial, powder, and ink systems, and streamline your formulations from lab to plant.

- Contact us: email: sales01@cqtitaniumdioxide.com

- Visit our website: https://www.cqtitaniumdioxide.com

- Product page: Dongfang R5566 TiO2 Powder

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025