Sep . 05, 2024 07:48 Back to list

High-Quality 1250 Mesh Factories - Precision Manufacturing Solutions

Understanding 1250 Mesh Factories A Comprehensive Overview

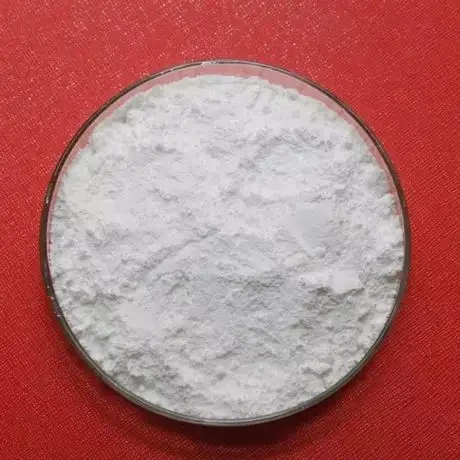

In the industrial realm, the term mesh refers to the size of particulate materials, particularly in the production of powders used in various applications

. When we mention 1250 mesh, we are looking at an extremely fine particle size that has significant implications for a variety of industries, including pharmaceuticals, food processing, and materials manufacturing. This article delves into the concept of 1250 mesh factories, their importance, processes involved, and their applications.A mesh indicates the number of openings in a screen or sieve per linear inch. Thus, a 1250 mesh means that there are 1250 openings in one linear inch of the screening surface. This fine mesh is capable of producing powdered materials that are incredibly uniform in size, with particle diameters typically around 10 microns or less. The significance of such fine powders cannot be underestimated, as they enhance product performance, improve bioavailability, and enable better mixing.

1250 mesh factories are specialized facilities designed utilizing sophisticated equipment and technologies to achieve such high levels of fineness in their products. The manufacturing process begins with the selection of raw materials, which are then subjected to grinding and milling. The use of advanced machinery, such as jet grinders, ball mills, and air classifiers, ensures that the end product not only meets the required particle size but also retains its desired physical and chemical properties.

1250 mesh factories

Quality control is paramount in these factories. Rigorous testing and certification processes are employed to ensure that the powders meet industry standards. Equipment such as laser diffraction analyzers and sieve shakers are utilized to assess particle size distribution, ensuring consistency and quality in the final output.

The applications of 1250 mesh materials are vast. In the pharmaceutical industry, such fine powders are crucial for producing high-quality tablets and capsules with improved dissolution rates. In food processing, they are used in flavorings, spices, and additives, allowing for better texture and enhanced flavor. Furthermore, materials like 1250 mesh silica gel are popular in the cosmetics industry due to their ability to improve the feel and appearance of products.

In conclusion, 1250 mesh factories play a vital role in numerous industries by producing ultra-fine powders that enhance product quality and performance. As technology continues to advance, the capabilities of these factories will expand, further emphasizing their importance in the modern manufacturing landscape. The ongoing demand for finer materials ensures that 1250 mesh production will remain a key focus in the pursuit of innovation and excellence across various sectors.

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025