Nov . 02, 2024 08:29 Back to list

titanium iv oxide anatase manufacturer

Titanium IV Oxide (Anatase) Manufacturers An Overview

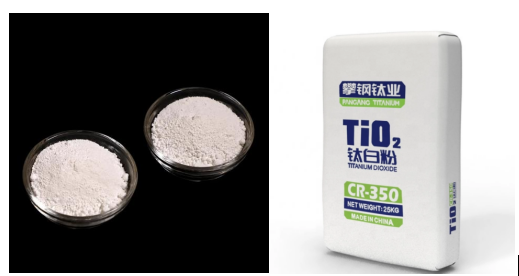

Titanium IV oxide, commonly known as titanium dioxide (TiO2), is a widely utilized compound in various industries due to its remarkable properties. Among its three primary crystal forms—anatase, rutile, and brookite—anatase has garnered significant attention, especially in applications including photocatalysis, pigments, and solar energy conversion. The manufacture of anatase titanium dioxide has become essential due to its unique characteristics that enhance the performance of many products.

Titanium IV Oxide (Anatase) Manufacturers An Overview

One of the key advantages of anatase over other forms of titanium dioxide is its enhanced photocatalytic activity, which is largely attributed to its particular crystal structure and electron band gap. This has led to a surge in interest from manufacturers aiming to develop advanced materials for use in photocatalytic coatings, which can be applied to surfaces for self-cleaning purposes or to reduce harmful pollutants in the air and water.

titanium iv oxide anatase manufacturer

The manufacturing process for titanium IV oxide (anatase) typically involves several steps, including the extraction of titanium ores, refining to produce titanium tetrachloride (TiCl4), and subsequent hydrolysis to achieve the desired phase and morphology. Various synthesis methods, such as sol-gel, hydrothermal, and precipitation techniques, are employed, enabling manufacturers to tailor the properties of the anatase to fit specific applications.

Competitive pressures in the titanium dioxide market have driven manufacturers to invest in research and development to improve production efficiencies and minimize environmental impacts. As public awareness of sustainability grows, the shift towards greener production methods is becoming pivotal. Many manufacturers are adopting practices that reduce energy consumption and waste, thereby aligning with global goals for sustainable manufacturing.

In conclusion, the role of titanium IV oxide (anatase) manufacturers is increasingly crucial as industries evolve to embrace innovative technologies for environmental conservation and energy efficiency. With ongoing advancements in production techniques and applications, anatase titanium dioxide is poised to play a transformative role in various sectors, including catalysis, coatings, and renewable energy, thereby contributing to a more sustainable future.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025