Okt . 31, 2024 11:47 Back to list

Titanium Dioxide Producers in RC 20823 Industry and Their Innovations

Overview of RC 20823 Titanium Dioxide Manufacturers

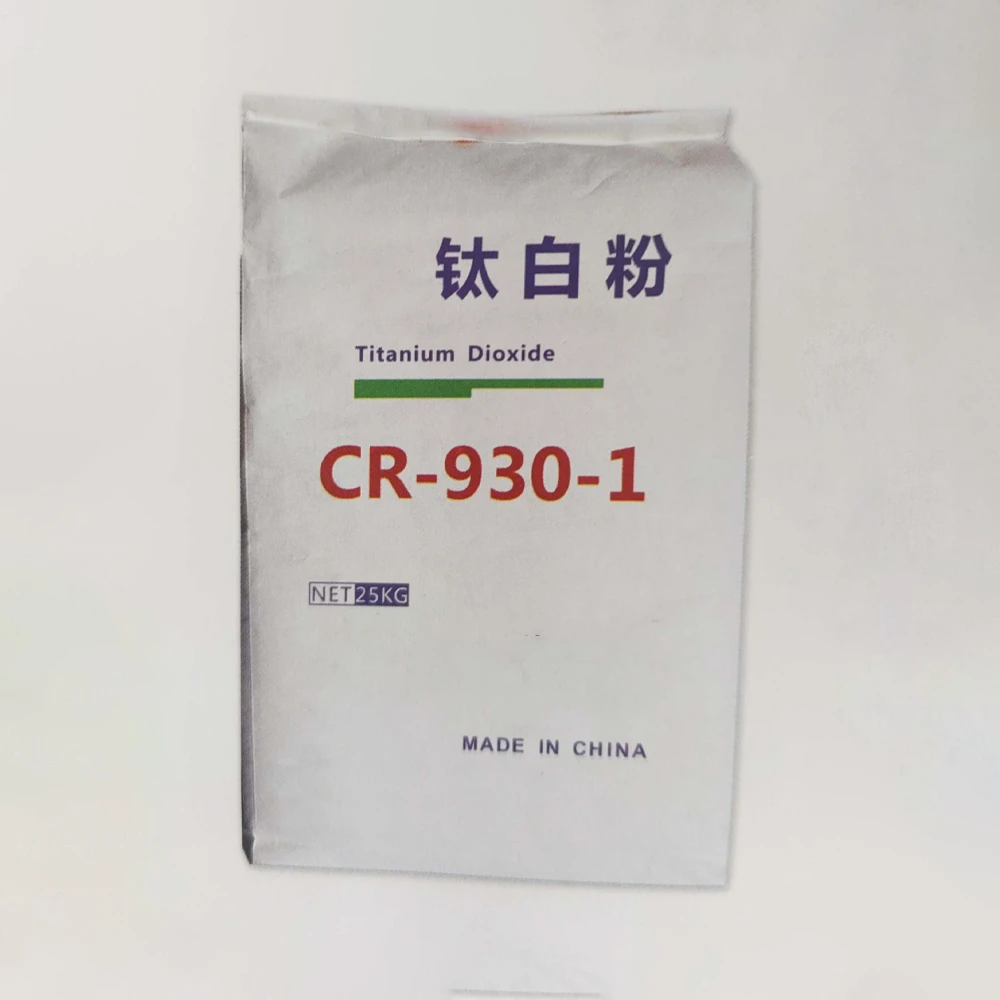

Titanium dioxide (TiO2) is a widely utilized white pigment known for its exceptional brightness and high refractive index. It is extensively used in various applications, including paints, coatings, plastics, paper, and cosmetics. Among the many grades of titanium dioxide produced, RC 20823 has gained recognition for its unique properties, attracting the attention of manufacturers seeking to deliver superior products across different industries.

RC 20823 is specifically formulated to provide excellent color consistency, high opacity, and durability, making it ideal for applications that require a robust white pigment. Its chemical structure, which consists of titanium and oxygen, allows it to reflect light effectively, enhancing the brightness and coverage of the substances it is mixed with. This attribute is particularly valuable in the manufacturing of paints and coatings, where a high level of opacity is essential to achieve vibrant colors and protect surfaces.

The manufacturing process of titanium dioxide typically involves two main methods the sulfate process and the chloride process. The sulfate method, although more traditional, involves the treatment of titanium ore with sulfuric acid, resulting in various impurities that must be carefully managed. In contrast, the chloride process, which is becoming increasingly popular, involves the use of chlorine gas to produce a purer form of titanium dioxide. This method not only enhances the quality of the final product but also reduces the environmental impact associated with titanium dioxide production.

rc 823 titanium dioxide manufacturers

Several manufacturers have stepped up to produce RC 20823 titanium dioxide, each employing unique technologies and methodologies to ensure high product quality and sustainability. Companies like Tronox, Chemours, and Huntsman are leading players in the titanium dioxide market, leveraging advanced techniques and optimizing their production processes to meet stringent industry standards. These manufacturers invest significantly in research and development to innovate and improve their products, focusing on improving performance while minimizing environmental footprints.

Sustainability is increasingly becoming a pivotal concern for manufacturers of titanium dioxide. As industries evolve and regulations tighten concerning emissions and waste management, producers are adopting eco-friendly practices. This includes utilizing waste materials in the production process, reducing water and energy consumption, and implementing effective waste management systems.

Moreover, with the growing demand for eco-conscious products, the need for high-performance titanium dioxide, such as RC 20823, is expected to rise. Industries are actively seeking pigments that not only perform well but also align with sustainability goals. Manufacturers are responding to this trend by promoting transparency in their sourcing and production practices and developing green products that meet customer expectations without compromising on quality.

In conclusion, RC 20823 titanium dioxide will continue to be a vital component in numerous applications due to its unique properties and versatility. The ongoing efforts by manufacturers to enhance product quality, adopt sustainable practices, and innovate will play a significant role in shaping the future of the titanium dioxide market and fulfilling the ever-evolving needs of various industries.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025