Okt . 21, 2024 05:11 Back to list

Titanium Dioxide Coatings Production and Factory Overview for Industrial Applications

The Utilization of Titanium Dioxide in Coatings Exploring Factory Production

Titanium dioxide (TiO2) is a widely utilized white pigment known for its excellent covering power, brightness, and durability. Its unique properties make it an essential component in various coatings, ranging from paints and varnishes to protective coatings and inks. This article delves into the significance of titanium dioxide in the coatings industry, highlighting the processes involved in its production, the role of factories in manufacturing, and the implications for product performance and environmental considerations.

Overview of Titanium Dioxide in Coatings

As one of the most commonly used inorganic compounds, titanium dioxide serves as a vital pigment due to its exceptional opacity and brightness. Coatings that incorporate TiO2 are prized for their ability to provide excellent coverage and resistance to ultraviolet (UV) light, making them suitable for both interior and exterior applications. The versatility of TiO2 extends beyond pigments; it is also used in performance-enhancing additives that improve the durability, corrosion resistance, and aesthetic qualities of coatings.

Production Processes of Titanium Dioxide

The manufacturing of titanium dioxide primarily occurs through two distinct processes the sulfate process and the chloride process

.1. Sulfate Process This method begins with the sulfation of ilmenite ore at high temperatures, producing a mixture of titanium and iron sulfate. This mixture is then purified and subjected to hydrolysis, resulting in the formation of titanium dioxide. This method is cost-effective and widely used, especially in settings where ilmenite is abundant. However, it generates considerable waste and requires careful environmental management.

2. Chloride Process In contrast, the chloride process is more environmentally friendly, albeit more expensive. Here, titanium-containing ores are reacted with chlorine gas at high temperatures to produce titanium tetrachloride (TiCl4). This compound is then purified and oxidized to yield high-purity titanium dioxide. The chloride process results in fewer by-products and offers better control over the properties of the titanium dioxide produced, making it a preferred choice for high-performance coatings.

The Role of Factories in Production

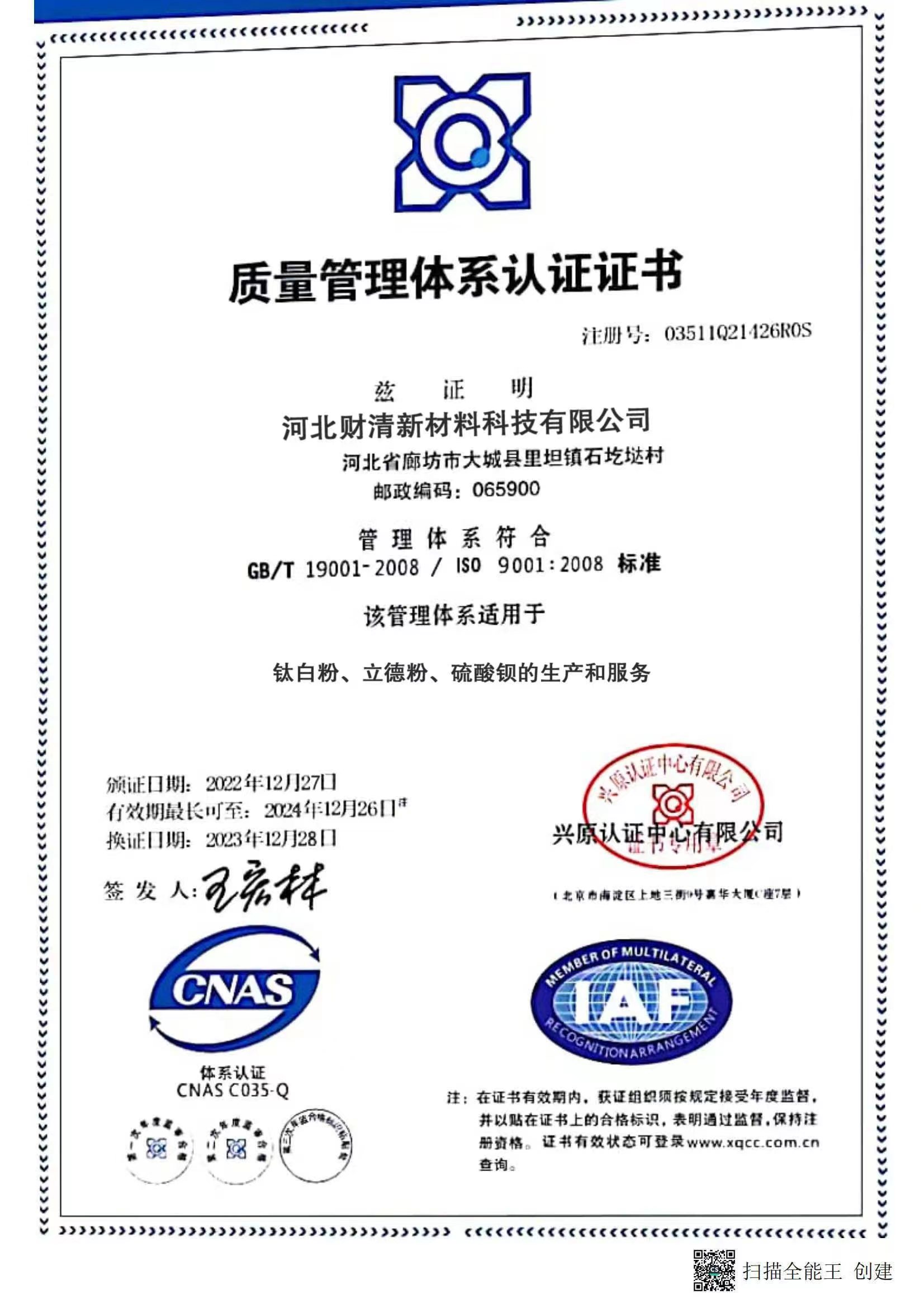

coatings titanium dioxide factories

Factories specializing in the production of titanium dioxide employ advanced technologies and stringent quality control measures to ensure the reliability and consistency of their products. These facilities are designed to handle large-scale production while minimizing environmental impacts. The integration of automation and digital technologies enables manufacturers to optimize processes, reduce waste, and ensure compliance with safety regulations.

Manufacturers often invest in research and development to enhance the functionality of titanium dioxide in coatings. Innovations such as surface modification techniques and the development of nano-sized titanium dioxide particles have opened up new applications and performance enhancements in coatings. For instance, nano-TiO2 can improve the photocatalytic properties of coatings, leading to self-cleaning surfaces and enhanced durability.

Environmental Considerations

While titanium dioxide has many advantageous properties, its production and application present environmental challenges. The sulfate process, in particular, has been criticized for its potential to generate significant waste and pollute waterways. This has led to stricter regulations and a push for more sustainable production methods within the industry.

Furthermore, there are concerns surrounding the inhalation of titanium dioxide particles, leading to scrutiny regarding worker safety and environmental exposure. As a result, many companies are investing in cleaner technologies and practices to mitigate risks and enhance workplace wellness.

Future Prospects

The future of titanium dioxide in the coatings industry looks promising, driven by continued innovations and a growing emphasis on sustainability. Manufacturers are exploring bio-based alternatives and developing formulations that utilize less titanium dioxide without compromising quality. The quest for more eco-friendly products aligns with global trends towards sustainability, and the coatings industry is no exception.

In conclusion, titanium dioxide remains a cornerstone of the coatings industry, offering performance benefits that are hard to replicate. As factories adapt to meet environmental challenges and embrace new technologies, the role of titanium dioxide will likely evolve, paving the way for safer and more sustainable coatings solutions. The synergy between innovation and sustainability will define the future of titanium dioxide production and its applications in coatings, ensuring it continues to meet the demands of an ever-evolving market.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025