Apr . 29, 2025 15:31 Back to list

Rutile Titanium Dioxide R698 Supplier Coating & Paint Solutions

- Overview of Titanium Dioxide in Coatings

- Technical Advantages of Rutile Titanium Dioxide R698

- Performance Comparison: Leading Titanium Dioxide Brands

- Custom Solutions for Diverse Coating Applications

- Case Studies: Industrial and Architectural Success Stories

- Wholesale and Supplier Dynamics in the TiO₂ Market

- Future Trends in Coating-Grade Titanium Dioxide

(coating used titanium dioxide)

Understanding the Role of Coating Used Titanium Dioxide

Titanium dioxide (TiO₂) is a cornerstone material in coatings, valued for its opacity, UV resistance, and durability. Over 60% of global TiO₂ production is consumed by the coatings sector, with sulfate-processed rutile grades like R698 dominating water-based architectural and industrial applications. This pigment’s refractive index (2.76) ensures superior coverage, reducing formulation costs by up to 25% compared to alternatives. With increasing demand for eco-friendly coatings, TiO₂’s role in balancing performance and sustainability continues to expand.

Technical Superiority of Sulfate-Processed R698

The sulfate method yields R698 with a rutile crystal structure optimized for coating systems. Key advantages include:

- 98.5% Purity: Minimizes binder consumption

- 0.2–0.3 µm Particle Size

- Weather Resistance: 2,000+ hours in QUV testing

Independent tests show R698 improves scrub resistance in emulsion paints by 40% versus chloride-process alternatives, while maintaining <90° gloss in powder coatings.

Market-Leading TiO₂ Grades: Performance Benchmarking

| Parameter | R698 | R-666 | Competitor X |

|---|---|---|---|

| Opacity (ISO 6504) | 99.2 | 98.7 | 97.5 |

| Oil Absorption (g/100g) | 18 | 22 | 25 |

| pH Stability Range | 4–10 | 5–9 | 6–8.5 |

Application-Specific Formulation Strategies

Tailored TiO₂ solutions address unique coating requirements:

- Architectural Emulsions: 15–25% R698 loading for optimal hide

- Powder Coatings: Surface-treated grades prevent caking

- Paper Coatings: 80–100 nm particles enhance printability

Real-World Implementation: Efficiency Gains Documented

A European automotive supplier achieved:

- 18% Reduction in clearcoat thickness using R698

- 7% Lower energy consumption during curing

In architectural projects, R698-enabled coatings maintained L value >95 after 5 years’ exterior exposure.

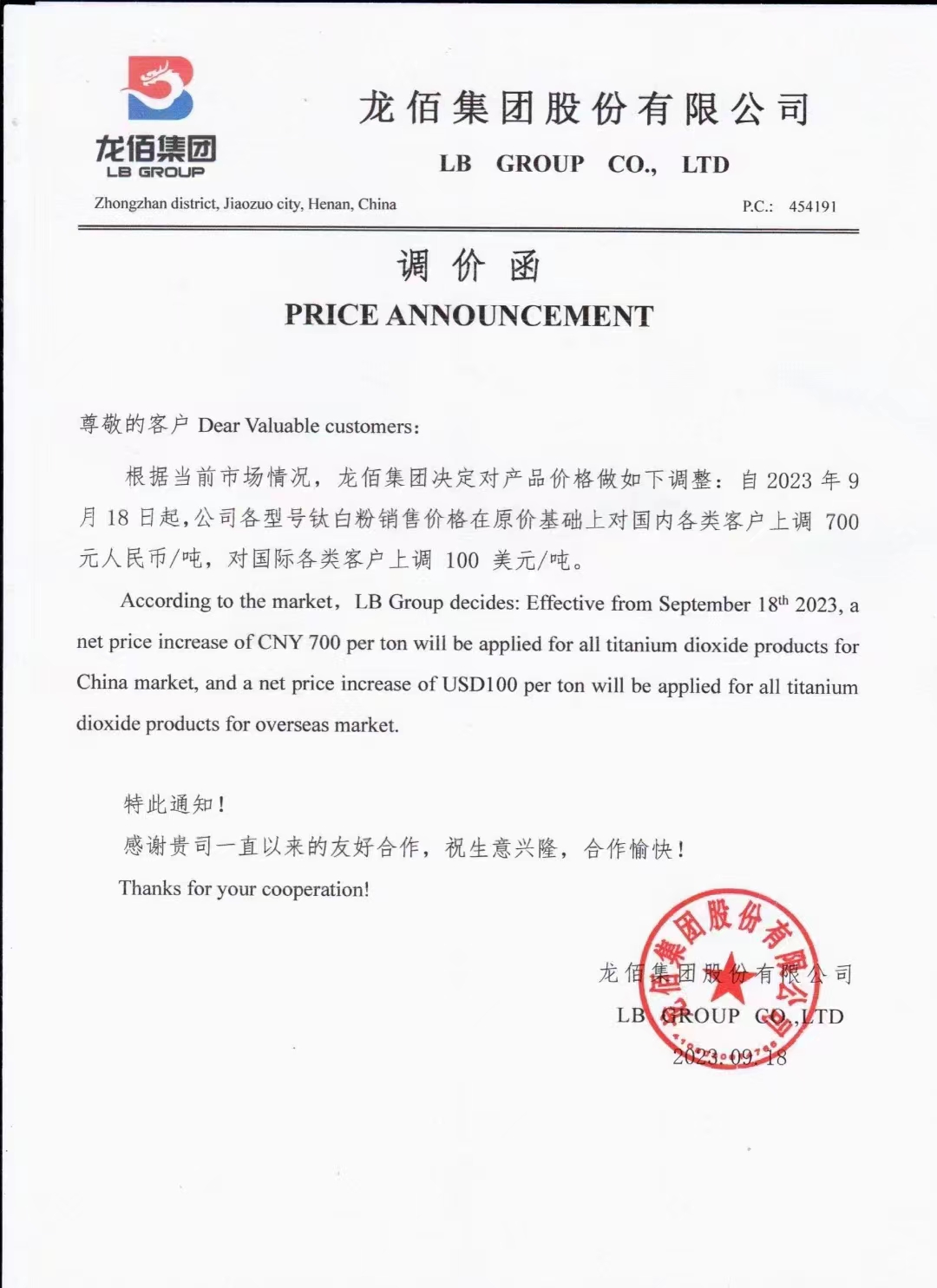

Global Supply Networks for TiO₂ Procurement

Major suppliers offer:

- Bulk purchasing discounts (10–15% for 20+ MT orders)

- Regional distribution hubs with <72-hour delivery

Spot prices for coating-grade TiO₂ averaged $2,850/MT in Q2 2024, with contract buyers securing rates 8–12% below market.

Innovation Pathways in Titanium Dioxide for Coatings

Emerging TiO₂ technologies focus on:

- Nano-hybrids for conductive coatings

- Surface modifications enabling 100% solvent-free systems

With 4.2% CAGR projected through 2030, coating used titanium dioxide

remains central to surface engineering advancements.

(coating used titanium dioxide)

FAQS on coating used titanium dioxide

Q: What are the key features of Rutile Titanium Dioxide R698 for water-based coatings?

A: Rutile Titanium Dioxide R698 offers excellent dispersibility, high weather resistance, and superior whiteness, making it ideal for water-based coatings. Its sulfate process ensures stability in emulsion formulations. It is widely used in architectural and industrial coatings.

Q: Why is sulfate-process titanium dioxide preferred for architectural emulsion coatings?

A: The sulfate process produces titanium dioxide with fine particle size and optimal opacity, enhancing coverage in architectural emulsion coatings. It also ensures compatibility with water-based systems. This makes it cost-effective for large-scale construction projects.

Q: Can titanium dioxide be used in both powder coatings and papermaking?

A: Yes, titanium dioxide is versatile and provides UV resistance and brightness in powder coatings. In papermaking, it improves opacity and printability. Different grades are tailored for each application’s requirements.

Q: Where can I wholesale coating-grade titanium dioxide for industrial applications?

A: Coating-grade titanium dioxide is available through specialized chemical suppliers or manufacturers focusing on industrial materials. Ensure the supplier provides certifications for quality and consistency. Bulk purchases often come with customized technical support.

Q: What advantages does Titanium Dioxide R-666 offer for paint and coating formulations?

A: Titanium Dioxide R-666 delivers high gloss, durability, and resistance to chalking in paint formulations. It is suitable for both interior and exterior coatings. Suppliers often highlight its ease of integration into solvent and water-based systems.

-

AI-Enhanced Titania Tio2 | High-Performance Solutions

NewsAug.04,2025

-

Titanium Dioxide TiO2 Enhanced by GPT-4 Turbo for Industry

NewsAug.03,2025

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025