Okt . 15, 2024 03:41 Back to list

chlorination process titanium dioxide manufacturer

The Chlorination Process in Titanium Dioxide Manufacturing

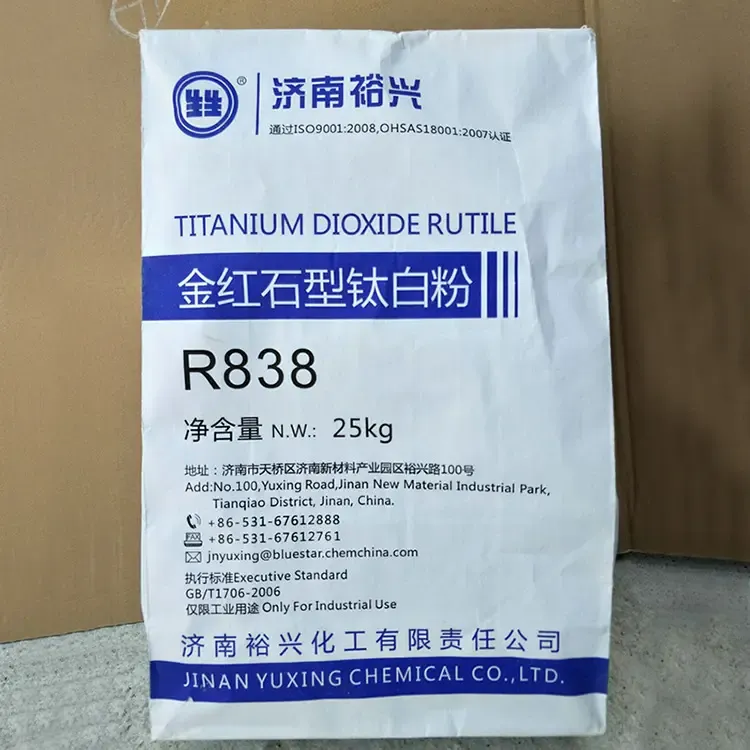

Titanium dioxide (TiO2) is a widely used white pigment in various industries, including paints, coatings, plastics, and cosmetics. Its exceptional brightness, durability, and UV resistance make it a preferred choice for manufacturers. One of the key methods employed in producing titanium dioxide is the chlorination process, a technique that has gained significant attention due to its efficiency and quality output.

The chlorination process for titanium dioxide begins with the extraction of titanium ores, primarily ilmenite (FeTiO3) or rutile (TiO2). These ores are subjected to a series of chemical treatments to separate titanium from impurities. In the chlorination method, titanium in the ore is converted to titanium tetrachloride (TiCl4) through a reaction with chlorine gas (Cl2) at high temperatures, typically between 900 and 1,100 degrees Celsius.

The chlorination reaction can be summarized as follows

\[ \text{TiO2 (s) + 2Cl2 (g) → TiCl4 (g) + O2 (g)} \]

This process yields titanium tetrachloride in gaseous form, which is then purified through distillation

. The purity of TiCl4 is crucial, as impurities can negatively affect the quality of the final titanium dioxide product.chlorination process titanium dioxide manufacturer

After purification, titanium tetrachloride undergoes hydrolysis, where it reacts with water to form titanium dioxide. This step is essential as it converts the gaseous TiCl4 into solid TiO2. The hydrolysis process can be represented by the following equation

\[ \text{TiCl4 (g) + 2H2O (l) → TiO2 (s) + 4HCl (g)} \]

The titanium dioxide produced through hydrolysis is in the form of fine particles. These particles can be further processed to achieve the desired properties, such as particle size and surface treatment, which enhance their performance in applications.

The chlorination process has several advantages over the sulfate method, another common method for producing titanium dioxide. One of the main benefits is that it yields a higher purity product with fewer impurities, resulting in better performance in applications. Additionally, the chlorination process produces less waste and requires fewer raw materials, making it a more environmentally friendly option. The chlorine used in the process can be recycled, minimizing the overall environmental impact.

Furthermore, the chlorination method offers flexibility in production scale and allows for the manufacture of specialized titanium dioxide grades tailored to meet the specific needs of various industries. This adaptability has made the chlorination process particularly attractive to manufacturers looking to innovate and meet stringent product specifications.

In conclusion, the chlorination process is a vital and efficient method for producing titanium dioxide. Its ability to yield high-purity titanium dioxide with minimal environmental impact makes it a preferred choice among manufacturers. As industries continue to seek sustainable and high-performance materials, the chlorination process will likely maintain its significance in titanium dioxide production, further solidifying its role in modern manufacturing and countless applications. The ongoing advancements in technology may also enhance this process, making it even more efficient and environmentally friendly in the years to come.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025