Nov . 24, 2024 03:41 Back to list

anatase grade titanium dioxide factory

Exploring the Production of Anatase Grade Titanium Dioxide

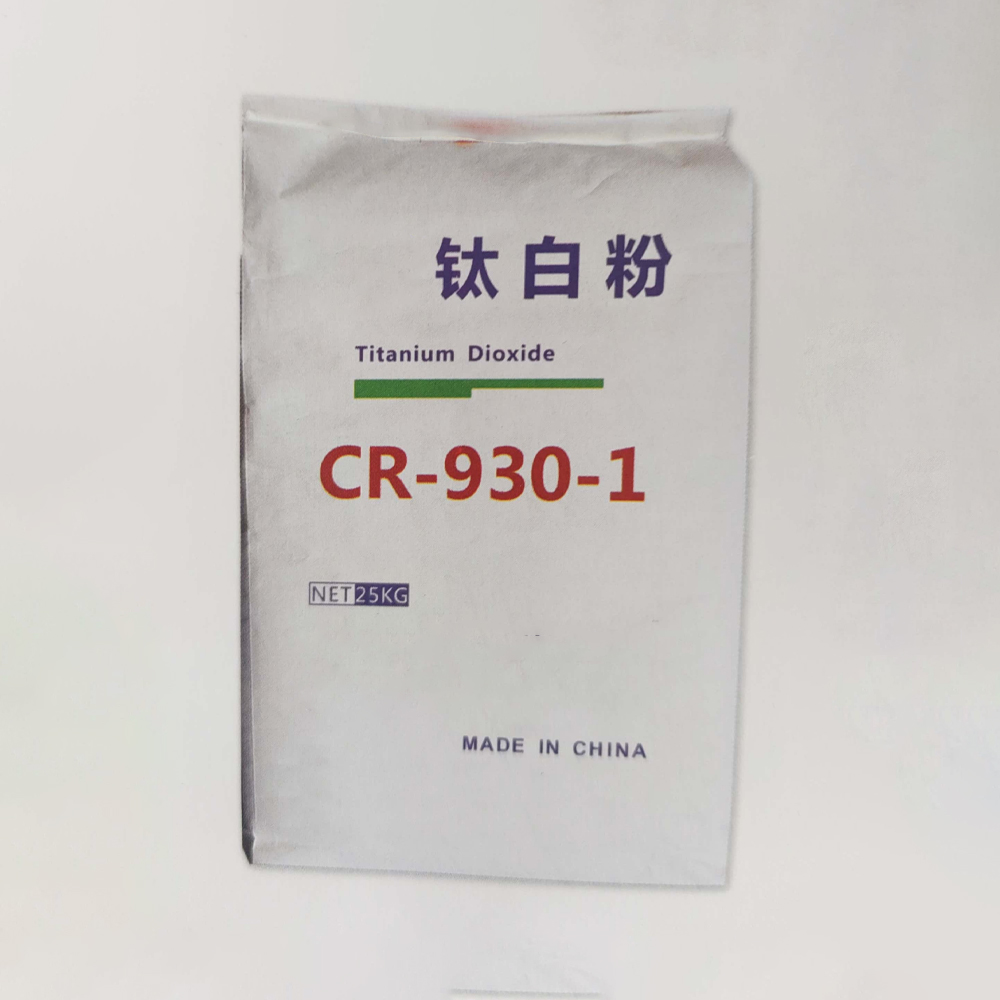

Titanium dioxide (TiO2) is one of the most widely utilized minerals across various industries, owing to its remarkable properties such as high opacity, brightness, and resistance to UV light. Among its forms, anatase grade titanium dioxide has garnered significant attention due to its unique characteristics that make it particularly valuable in specific applications. This article explores the production processes, uses, and market trends related to anatase grade titanium dioxide.

The manufacturing of anatase grade titanium dioxide typically begins with the extraction of titanium-bearing ores, such as ilmenite and rutile. These ores undergo a series of processes, including crushing, grinding, and leaching, to separate titanium dioxide from impurities. The extracted titanium dioxide is then further processed to produce the anatase form, which is accomplished through hydrolysis or sulfation processes. During these procedures, the conditions like temperature and pH levels are carefully controlled to ensure the desired crystal structure and purity levels of the anatase phase are achieved.

Anatase grade titanium dioxide is characterized by its tetragonal crystal structure, which provides it with distinct properties compared to the more stable rutile form. It has a higher surface area and, thus, enhanced photocatalytic activity, making it suitable for various applications. Notably, it is primarily used in the production of pigments for paints, coatings, and plastics. In the paint industry, its ability to provide excellent coverage and durability is unparalleled, making it a preferred choice among manufacturers.

anatase grade titanium dioxide factory

Furthermore, anatase grade titanium dioxide is increasingly being used in the production of sunscreen products

. Due to its effectiveness in blocking harmful UV radiation, it plays a crucial role in protecting skin health. Additionally, the photocatalytic properties of anatase enable its use in self-cleaning surfaces and pollutants degradation, further broadening its application scope.In terms of market dynamics, the demand for anatase grade titanium dioxide is witnessing growth, particularly in the Asia-Pacific region, where industrialization and urbanization are on the rise. However, fluctuations in raw material prices and environmental regulations concerning titanium dioxide production processes pose challenges for manufacturers. Companies are thus investing in research and development to adopt more sustainable production methods and improve the efficiency of TiO2 usage.

Emerging innovations, such as nano-sized anatase titanium dioxide, are also gaining traction, as they offer enhanced properties and open new avenues for applications in electronics and environmental remediation. This continuous evolution in the production techniques and applications of anatase grade titanium dioxide highlights its significance in the modern industry.

In conclusion, anatase grade titanium dioxide remains a vital substance in multiple sectors, driven by its unique properties and growing demand. The manufacturing processes and market trends indicate a promising future for this versatile mineral, as it evolves to meet the ever-changing needs of various industries. As we move forward, the focus on sustainability and innovation will likely shape the future of anatase titanium dioxide production, ensuring its relevance for years to come.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025