ທ.ວ. . 14, 2024 05:06 Back to list

titanium dioxide r-996 factories

Understanding Titanium Dioxide R-996 Factories

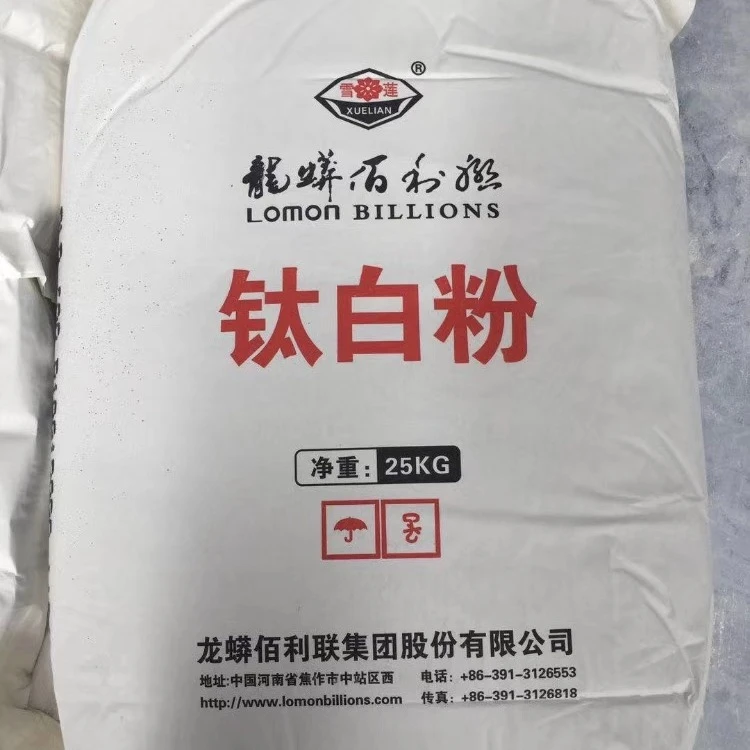

Titanium dioxide (TiO₂) is one of the most widely used white pigments in the world. Renowned for its excellent opacity, brightness, and durability, it finds applications in various industries, including paints, coatings, plastics, paper, and cosmetics. Among the many grades of titanium dioxide, R-996 is particularly notable for its high performance and versatility. This article will delve into titanium dioxide R-996 factories, exploring their significance, production processes, and the environmental considerations surrounding them.

Significance of Titanium Dioxide R-996

R-996 is a type of titanium dioxide that is known for its exceptional properties. It offers superior hiding power and is effective in diffusing light, making it an ideal choice for applications requiring high whiteness and covering strength. R-996 is predominantly used in high-end coatings, inks, and plastics, where it's crucial to maintain color stability and fade resistance in exterior applications. Its use extends to various sectors, including automotive, construction, and consumer goods, emphasizing the importance of understanding the production and sourcing of this material.

The Production Process

The production of titanium dioxide involves several complex processes. Most titanium dioxide is manufactured through two primary methods the sulfate process and the chloride process. The choice of process can influence the characteristics of the final product, including discoloration, particle size, and surface treatment.

1. Sulfate Process This is the older and more established method for producing titanium dioxide. It involves the reaction of ilmenite (a naturally occurring mineral) with sulfuric acid. The resulting titanium sulfate is further processed to yield titanium dioxide pigment. However, this method typically generates more waste and is less environmentally friendly compared to the chloride process.

titanium dioxide r-996 factories

2. Chloride Process This modern method has gained popularity due to its efficiency and lower environmental impact. In this process, titanium feedstocks are reacted with chlorine gas at high temperatures, converting them into titanium tetrachloride. This is then oxidized to produce titanium dioxide. The chloride process tends to produce a purer product and results in less waste, making it a preferred method for producing high-quality titanium dioxide, such as R-996.

Additionally, titanium dioxide production requires strict quality control measures to maintain the desired characteristics of R-996. Factories often invest in advanced technologies for monitoring and quality assurance to minimize variations in the product.

Environmental Impact and Sustainability

The production of titanium dioxide, particularly through the sulfate process, has raised environmental concerns. The generation of waste byproducts and the use of hazardous materials necessitate stringent controls and regulations. Factories producing R-996 must adhere to environmental laws to mitigate pollution and promote sustainability.

Many manufacturers are now exploring innovative solutions to reduce their environmental footprint. These include implementing closed-loop systems to recycle waste materials and reduce water usage. Additionally, using more sustainable raw materials and exploring alternative production methods are becoming key focus areas. Factories are also investing in research to find ways to reduce energy consumption during production, contributing to a more sustainable future for the industry.

Conclusion

Titanium dioxide R-996 factories play a vital role in the global pigment market, providing an essential ingredient for various applications. Understanding the processes and challenges involved in its production is crucial for stakeholders in the industry. As the demand for environmentally friendly practices grows, manufacturers are working toward more sustainable methods, ensuring that the production of titanium dioxide can meet both market needs and environmental responsibilities. By fostering innovation and adhering to regulatory standards, the titanium dioxide industry can continue to thrive while minimizing its impact on the planet. In an era where sustainability is paramount, the evolution of titanium dioxide R-996 production represents a significant step towards a more responsible future.

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025

-

High Quality Titanium Dioxide Used in Rubber – Trusted Supplier & Factory Price

NewsJul.08,2025

-

High Purity Barium Sulfate Particle Size - Wholesale Manufacturer from China

NewsJul.07,2025

-

Premium Titanium Dioxide Lomon R-996 Supplier – Quality & Wholesale Price from China

NewsJul.07,2025

-

Top Titanium Manufacturers in China - Quality Titanium Dioxide Supplier & Production Line Solutions

NewsJul.06,2025

-

OEM Titanium White Supplier & Factory – High Purity, Consistent Quality for Industrial Use

NewsJul.06,2025