ພ.ຈ. . 08, 2024 00:28 Back to list

Suppliers of Titanium Dioxide Formulations and Applications for Various Industries

Understanding Titanium Dioxide Formula Suppliers

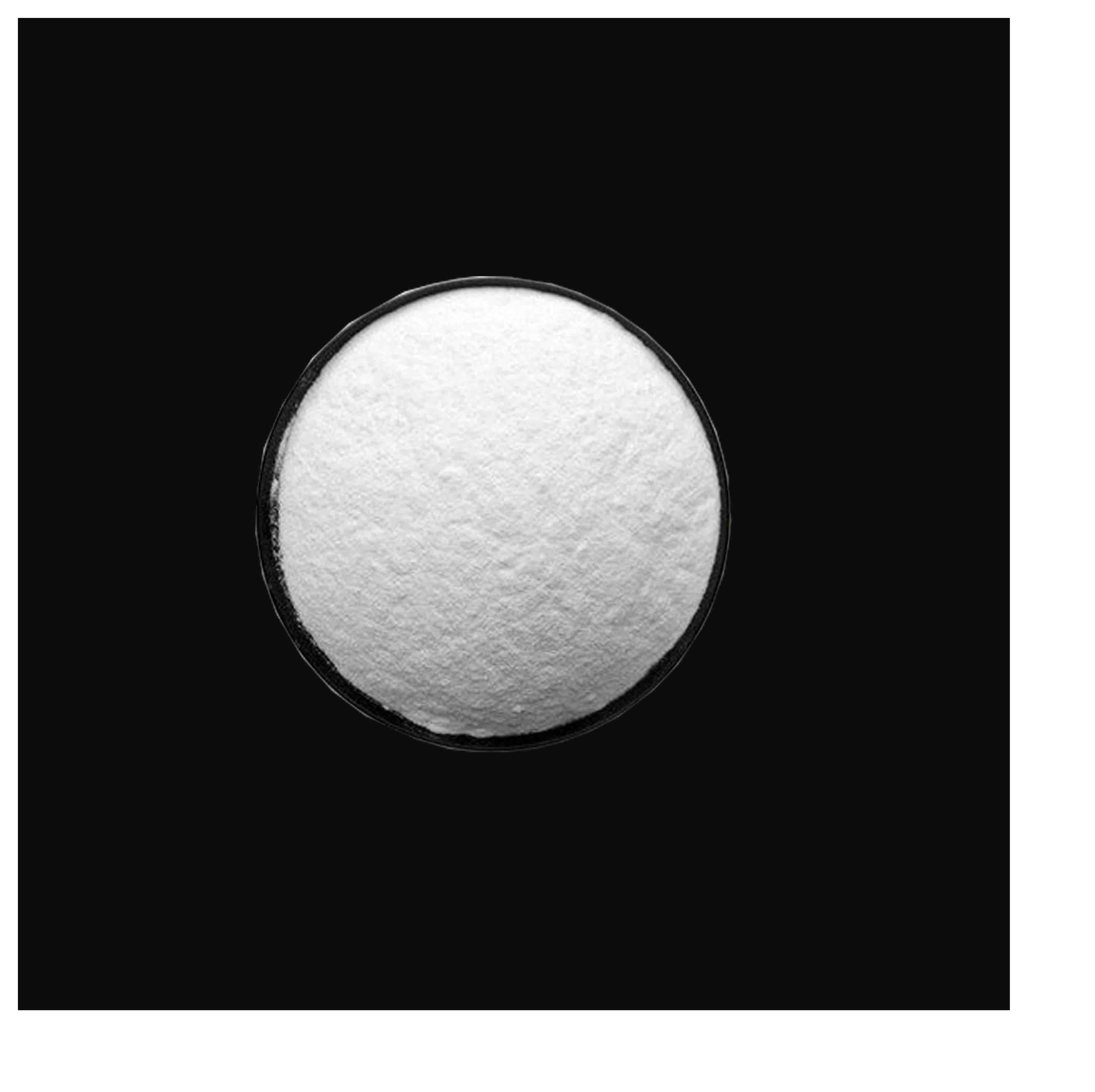

Titanium dioxide (TiO2) is a naturally occurring mineral that has garnered significant attention in various industrial applications due to its unique properties. Renowned for its high refractive index and strong ultraviolet (UV) light absorption, titanium dioxide is primarily used as a white pigment in paints, coatings, plastics, and cosmetics, as well as in applications like food processing and pharmaceuticals. Given its widespread use and importance, the role of titanium dioxide formula suppliers becomes crucial in ensuring that industries have access to high-quality raw materials.

The Role of Suppliers in the Titanium Dioxide Market

Suppliers of titanium dioxide formula play a key role in the market by providing manufacturers with essential materials that adhere to industry standards. These suppliers ensure that the titanium dioxide produced meets specific criteria required for various applications, including particle size, purity, and surface treatment. The two main types of titanium dioxide are rutile and anatase, each offering distinct properties that cater to different industries. For instance, rutile titanium dioxide is prized for its superior dispersibility and durability, making it ideal for outdoor coatings, whereas anatase may be preferred for indoor applications due to its lower cost and satisfactory performance.

Quality Assurance and Consistency

One of the most critical aspects of sourcing titanium dioxide is the assurance of quality and consistency. Suppliers employ stringent quality control measures to guarantee that the titanium dioxide delivered is free from impurities and meets the specifications laid out by manufacturers. This includes conducting rigorous testing on the chemical composition, physical properties, and performance characteristics of the product. Customers can rely on accredited suppliers to provide detailed documentation of these tests, ensuring that the material meets regulatory and safety standards.

Innovation and Adaptation

titanium dioxide formula suppliers

The titanium dioxide market is continually evolving, with advancements in technology and changing customer preferences leading suppliers to adapt their offerings. Innovative formulations of titanium dioxide have emerged, often enhanced through surface treatments to improve performance in specific applications. For example, hydrophobic and hydrophilic titanium dioxide can be produced to cater to different application needs, allowing for improved dispersion in coatings or enhanced photocatalytic properties for environmental applications.

Suppliers also focus on sustainability, responding to growing environmental concerns by sourcing materials responsibly and reducing the ecological footprint of production processes. This includes developing methods to recycle waste products and utilizing green chemistry principles to minimize the impact on the environment. Companies that prioritize sustainability not only meet regulatory requirements but also enhance their marketability to environmentally conscious consumers.

Global Supply Chains and Logistics

In a globalized economy, the management of supply chains and logistics is vital for titanium dioxide suppliers. As demand for TiO2 rises worldwide, especially in regions such as Asia-Pacific, suppliers must navigate international regulations, tariffs, and shipping logistics to deliver products efficiently. Establishing a robust supply chain allows suppliers to respond quickly to market changes and customer demands, ensuring that manufacturers have a steady supply of the materials they need.

For many manufacturers, the relationship with titanium dioxide suppliers goes beyond mere transactions; it involves forming strategic partnerships. Suppliers who provide technical support, product customization, and efficient logistics are often preferred over competitors. This collaborative approach fosters innovation and makes it easier for manufacturers to develop new products that meet the specific needs of their target markets.

Conclusion

In conclusion, titanium dioxide formula suppliers are integral to the industrial landscape, providing high-quality materials critical for a plethora of applications. With their focus on quality assurance, innovation, and sustainable practices, these suppliers not only support manufacturers but also contribute to the overall advancement of the titanium dioxide market. As industries continue to grow and evolve, the importance of reliable suppliers who can adapt to changing demands and technological advances will remain a cornerstone of success in utilizing titanium dioxide effectively across various sectors. Whether for coatings, plastics, or specialized applications, the partnership between manufacturers and titanium dioxide suppliers will pave the way for continued innovation and growth in the industry.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025