ທ.ວ. . 18, 2024 06:57 Back to list

l titanium dioxide factories

The Role of Titanium Dioxide Factories in Modern Industry

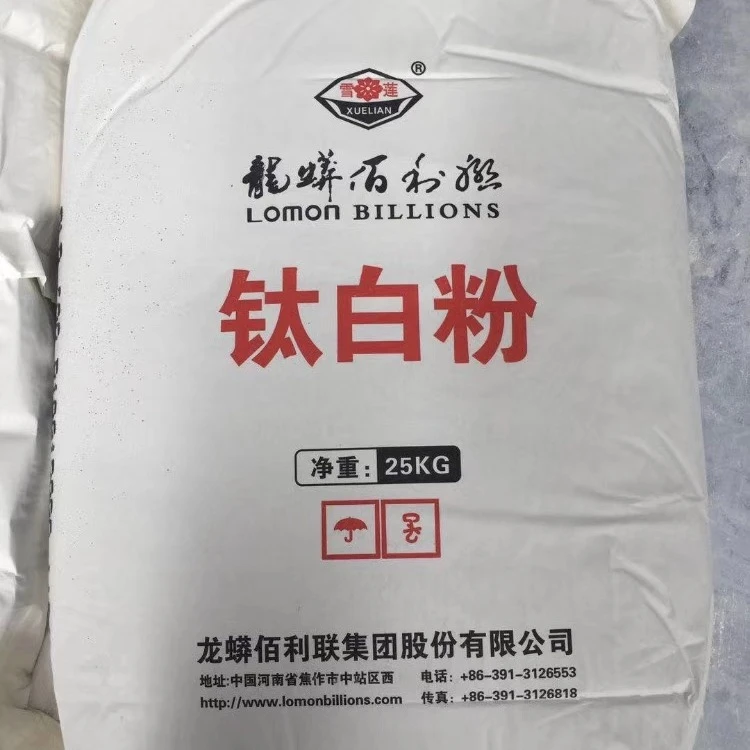

Titanium dioxide (TiO2) is a vital compound used in a myriad of applications, most notably as a pigment in paints, coatings, plastics, and paper. With its high refractive index and excellent UV resistance, it provides a bright whiteness and opacity that is unmatched by other materials. In recent years, the demand for titanium dioxide has soared, necessitating the establishment and expansion of titanium dioxide factories around the globe. This article will delve into the significance of these factories, their production processes, and their impact on various industries.

The Importance of Titanium Dioxide

Titanium dioxide is not merely a pigment; it is a versatile substance at the heart of many industrial processes. Its applications range from cosmetics, where it serves as a sunscreen agent due to its ability to block UV rays, to food products, where it is used as a colorant. Furthermore, the increasing focus on aesthetic and aesthetic enhancement has led to a rising demand for titanium dioxide in the automotive and construction industries. The global push towards sustainability has also sparked interest in TiO2’s potential in photocatalytic applications, where it can help in environmental remediation and energy generation.

Manufacturing Processes

The production of titanium dioxide primarily involves two methods the sulfate process and the chloride process.

1. Sulfate Process This traditional method involves the extraction of titanium from ilmenite or anatase ores. The ore is treated with sulfuric acid, which separates titanium from other components. This method produces a high-quality TiO2 pigment but is associated with higher costs and greater environmental impact due to the large amounts of waste generated.

2. Chloride Process In contrast, the chloride process is a more modern and efficient method. It begins with the chlorination of titanium-bearing ores, resulting in titanium tetrachloride (TiCl4). This compound is then oxidized to produce titanium dioxide. The chloride process is preferred by many manufacturers because it offers a higher purity product with lower production costs and reduced environmental footprint.

l titanium dioxide factories

Both processes require stringent safety measures and environmental regulations, due to the hazardous nature of the chemicals involved

. As a result, titanium dioxide factories are often equipped with advanced technologies to mitigate emissions and waste.Economic Impact

The establishment of titanium dioxide factories has significant economic implications. They contribute to job creation in various sectors, from construction to engineering and research and development. Moreover, these factories boost local economies by attracting associated businesses, such as suppliers and service providers. On a global scale, the industry's growth has a ripple effect, enhancing trade and investment opportunities, particularly in emerging markets.

Environmental Considerations

While titanium dioxide factories play a crucial role in industrial manufacturing, they also face scrutiny regarding their environmental impact. The production processes can lead to pollution if not properly managed. For instance, the sulfate process generates a considerable amount of acid waste, which can pose risks to local ecosystems. As such, many manufacturers are exploring sustainable practices, including waste recycling and cleaner production technologies, to mitigate these impacts.

Recent advancements in research are also paving the way for new applications of titanium dioxide in environmental technologies, such as air and water purification systems. By harnessing TiO2's photocatalytic properties, industries can develop solutions that contribute to cleaner environments.

Conclusion

Titanium dioxide factories are a cornerstone of modern manufacturing, providing essential materials for various industries. As demand continues to rise, the need for efficient and sustainable production methods becomes increasingly important. While these factories contribute significantly to economic growth and innovation, it is imperative to balance industrial output with environmental stewardship. By investing in clean technologies and sustainable practices, the titanium dioxide industry can continue to thrive and adapt to the changing demands of the global market. Moving forward, the collaboration between industry stakeholders, researchers, and policymakers will be crucial in addressing the challenges and leveraging the opportunities that lie ahead in the titanium dioxide landscape.

-

China Lithopone in China Supplier – High Quality Lithopone ZnS 30% Powder for Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Company – Premium TiO2 Powder Supplier & Manufacturer

NewsJun.10,2025

-

Fast Shipping 99% Pure TiO2 Powder CAS 13463-67-7 Bulk Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Manufacturers High-Purity R996 & Anatase

NewsJun.10,2025

-

Lithopone MSDS Factories - Production & Quotes

NewsJun.10,2025

-

High-Quality Titanium Dioxide in Water Suppliers - China Expertise 60

NewsJun.09,2025