ພ.ຈ. . 04, 2024 22:11 Back to list

calcium carbonate vs titanium dioxide suppliers

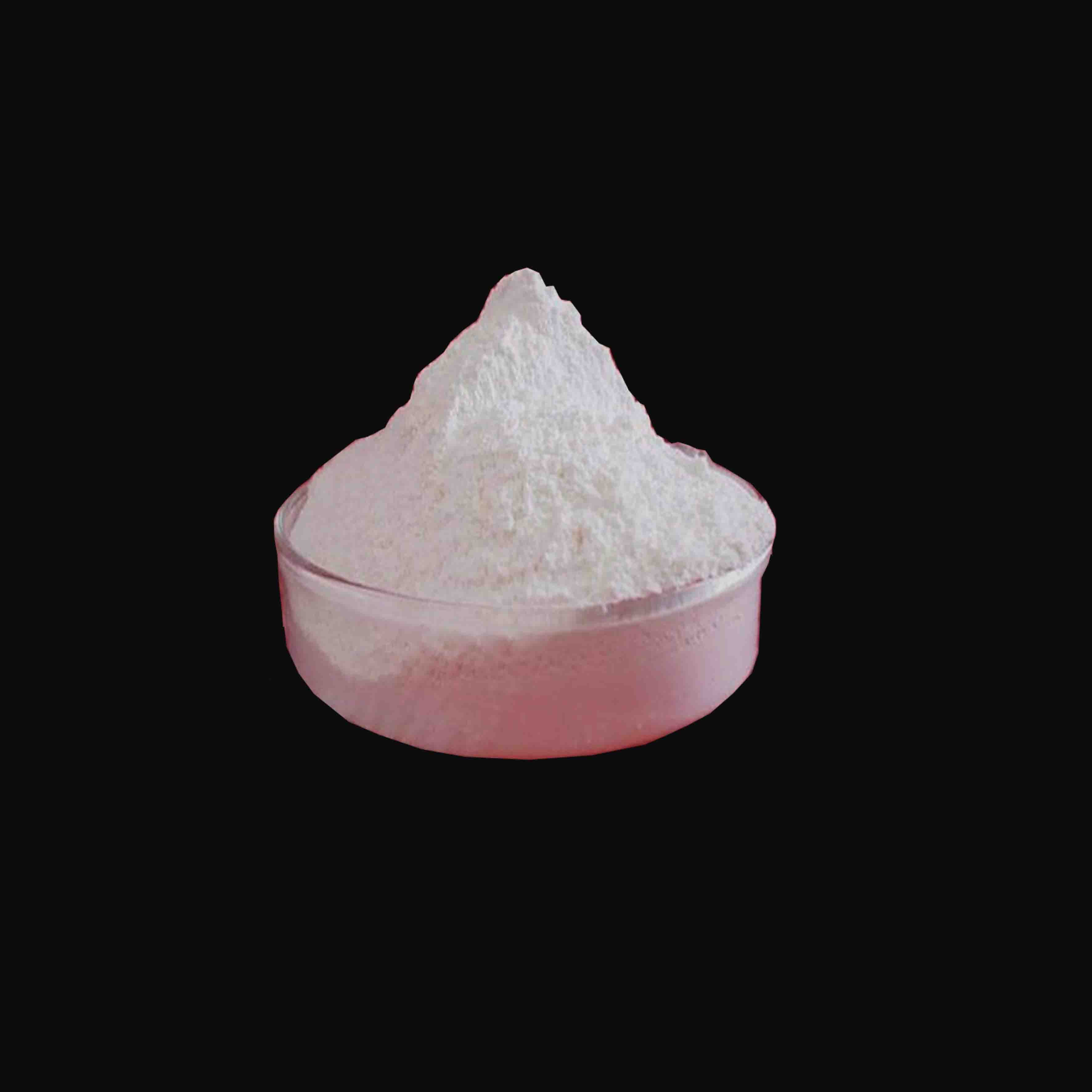

Calcium Carbonate vs. Titanium Dioxide A Comparative Analysis for Suppliers

In the realm of industrial minerals and pigments, calcium carbonate and titanium dioxide stand out as two essential substances widely utilized across various sectors. Each of these materials plays a significant role in different applications, from construction to coatings, and even in the food industry. This article aims to explore these two compounds from the perspective of suppliers, highlighting their characteristics, applications, and market dynamics.

Calcium carbonate (CaCO3) is a naturally occurring mineral that is abundant in limestone, marble, and chalk. It is primarily used as a filler, a pigment in paints, and as a soil conditioner in agriculture. One of the key advantages of calcium carbonate is its relatively low cost and ease of availability. This makes it a preferred choice for manufacturers looking for cost-effective solutions. Additionally, the mineral is non-toxic and environmentally benign, making it suitable for applications where safety and regulatory compliance are critical, such as in pharmaceuticals and food products.

On the other hand, titanium dioxide (TiO2) is renowned for its exceptional white pigment and is considered one of the most effective opacifiers available. In the coatings industry, titanium dioxide is valued for its opacity, brightness, and excellent UV resistance, which contribute to longer-lasting and more resilient products. However, the processing of titanium dioxide is more complex and resource-intensive compared to calcium carbonate, leading to higher costs. Suppliers of titanium dioxide often have to contend with fluctuating raw material costs and stringent environmental regulations, which can impact pricing and availability.

calcium carbonate vs titanium dioxide suppliers

When comparing suppliers of these two materials, it is essential to consider the specific requirements of end-users. For applications that demand high performance in terms of brightness and durability, titanium dioxide is often preferred despite its higher cost. For applications requiring bulk filler materials, such as in construction and plastics, calcium carbonate remains the go-to option due to its cost-effectiveness and availability.

Market trends also play a crucial role in shaping the landscape for suppliers of these two materials. The growth of the construction industry, particularly in emerging economies, has spurred demand for calcium carbonate in applications like cement and asphalt. Meanwhile, the increasing awareness of environmental sustainability is driving innovation in titanium dioxide formulations, with suppliers focusing on producing eco-friendly and high-performance alternatives.

In conclusion, both calcium carbonate and titanium dioxide present unique advantages and challenges for suppliers. As industries continue to evolve, the demand for both materials is expected to persist, albeit in varying capacities. Suppliers need to stay informed about market dynamics, technological advancements, and regulatory changes to remain competitive. Understanding the specific needs of their customers and adapting to trends will be essential for suppliers looking to thrive in this multifaceted market. As the demand for high-quality materials continues to grow, a strategic approach to sourcing and product development will pave the way for success in both the calcium carbonate and titanium dioxide sectors.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025