ພ.ຈ. . 25, 2024 15:01 Back to list

calcium carbonate vs titanium dioxide manufacturers

The Competitive Landscape of Calcium Carbonate and Titanium Dioxide Manufacturers

In the world of industrial minerals, calcium carbonate (CaCO3) and titanium dioxide (TiO2) are two of the most widely used compounds. They serve crucial roles in various applications, ranging from paints and coatings to plastics and pharmaceuticals. As demand for these materials continues to rise globally, the competitiveness among manufacturers of calcium carbonate and titanium dioxide has intensified. This article explores the characteristics of these minerals, their respective manufacturing processes, and the key players in the market.

Characteristics and Applications

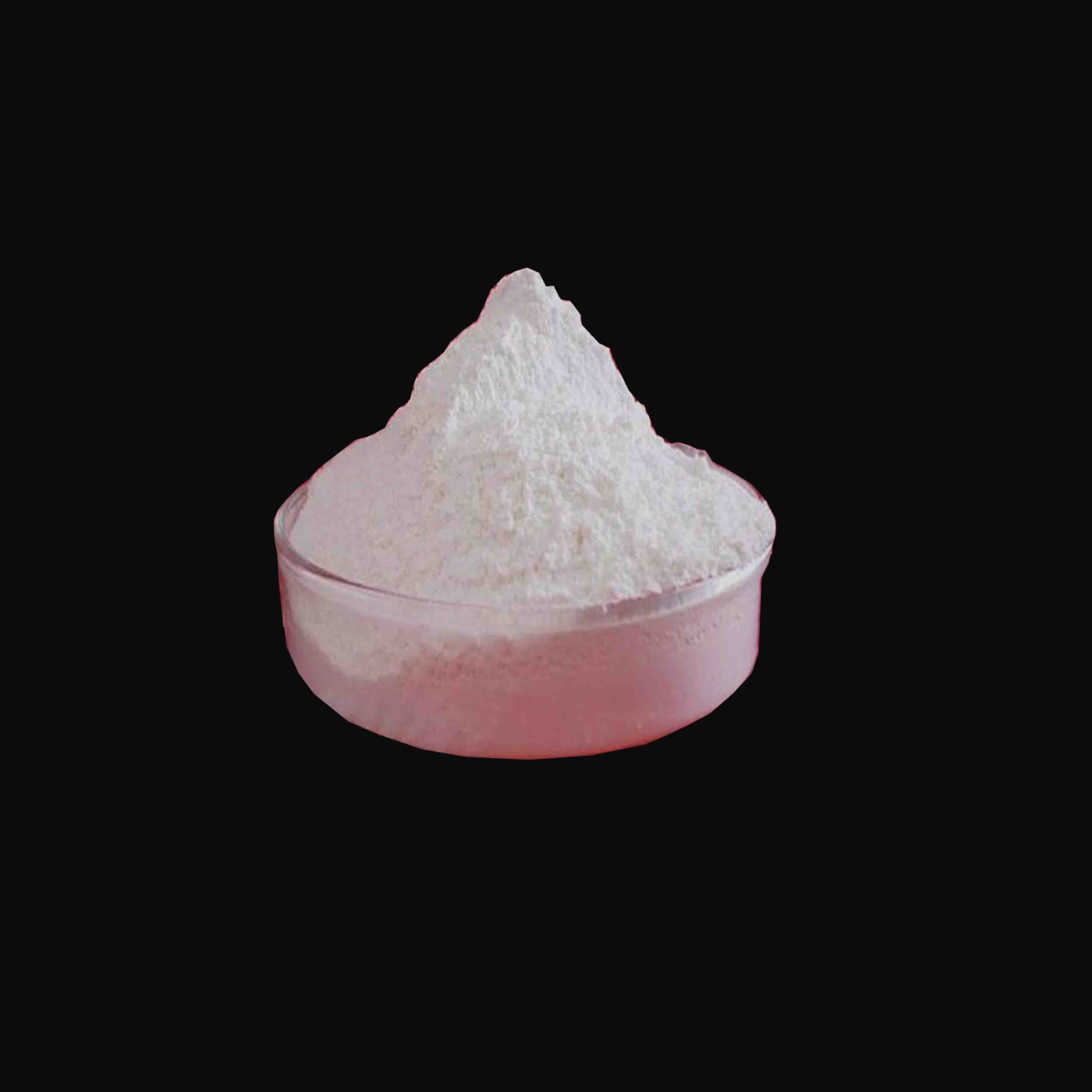

Calcium Carbonate Calcium carbonate is a naturally occurring mineral with a chemical formula of CaCO3. It exists in three primary forms calcite, aragonite, and vaterite. Its most common source is limestone, and it is often used as a filler in products like paper, plastics, paints, and rubber due to its high whiteness and low cost. Moreover, it serves an essential role in the construction industry as a basic ingredient in cement and as a soil conditioner in agriculture.

Titanium Dioxide Titanium dioxide, a white pigment with the formula TiO2, is renowned for its brightness and opacity. It is primarily derived from the minerals ilmenite and rutile. The pigment is widely utilized in coatings, plastics, and cosmetics due to its excellent UV resistance and stability. Its reflective properties make it a popular choice for applications where color vibrancy and durability are paramount.

Manufacturing Processes

The production of calcium carbonate typically involves mining and milling processes. Depending on its intended use, it can be ground to various particle sizes and can be either treated or un-treated. The manufacturing process often includes the use of small-scale operations that can provide significant flexibility in scale and product customization.

In contrast, the production of titanium dioxide is more complex, typically involving two main processes the sulfate process and the chloride process. The sulfate process involves the reaction of ilmenite with sulfuric acid, while the chloride process substitutes chlorine for sulfuric acid, producing a purer form of titanium dioxide. The choice of process affects both the quality of the final product and the environmental impact of production.

calcium carbonate vs titanium dioxide manufacturers

Key Players in the Market

The global market for calcium carbonate is characterized by a variety of players ranging from large multinational corporations to smaller regional manufacturers. Notable companies include Omya AG, Imerys, and Minerals Technologies Inc., all of which have extensive production capabilities. These manufacturers focus on technological advancements and sustainable practices to reduce their environmental footprint while maintaining product quality.

In the titanium dioxide sector, major players such as Chemours, Tronox, and Huntsman are prominent. The titanium dioxide market is highly concentrated, with a few companies dominating global supply. Firms in this industry are increasingly investing in research and development to improve production techniques and explore new applications for titanium dioxide, particularly in the fields of energy efficiency and environmental sustainability.

Market Trends and Challenges

Both the calcium carbonate and titanium dioxide markets are experiencing growth, driven by demand in various industries. The construction sector, for instance, is witnessing increased usage of both minerals due to ongoing infrastructure projects and a rise in residential construction. In the coatings and plastics industries, the shift towards eco-friendly products is pushing manufacturers to innovate, creating opportunities for those who can provide sustainable solutions.

However, challenges such as fluctuating raw material costs and environmental regulations loom over both sectors. The extraction of raw materials can lead to environmental degradation, and companies must navigate stringent regulations to minimize their ecological impact. Furthermore, competition from alternative materials, especially in coating applications, poses a risk to traditional markets.

Conclusion

In conclusion, the competitive landscape of calcium carbonate and titanium dioxide manufacturers reflects the broader trends in industrial mineral usage. As both minerals play pivotal roles across multiple sectors, maintaining a balance between production efficiency, product quality, and environmental responsibility will be crucial for manufacturers. With ongoing research and innovation, the future looks promising for companies willing to adapt to an ever-evolving market landscape. As the demand for high-performance materials continues to grow, so too will the opportunities for manufacturers who can meet the needs of a diverse clientele while adhering to sustainable practices.

-

High-Performance r6618 TiO2 for Superior Whitening and Versatility

NewsJul.28,2025

-

Titanium Dioxide B101 for High Purity and Brightness

NewsJul.28,2025

-

High Quality TiO2 for Superior Performance - Reliable Supply & Purity

NewsJul.27,2025

-

13463-67-7 Titanium Dioxide Using for Coating Supplier – High-Quality Rutile TiO2 for Paints

NewsJul.26,2025

-

High-Quality Titania TiO2 from Leading China Suppliers & Factories

NewsJul.25,2025

-

High Quality Titania TiO2 from Leading China Manufacturer and Supplier

NewsJul.24,2025