វិច្ឆិកា . 16, 2024 12:11 Back to list

Rutile Titanium Oxide Production Facilities and Their Impact on Industry

Titanium Oxide Rutile Factories A Beacon of Industrial Innovation

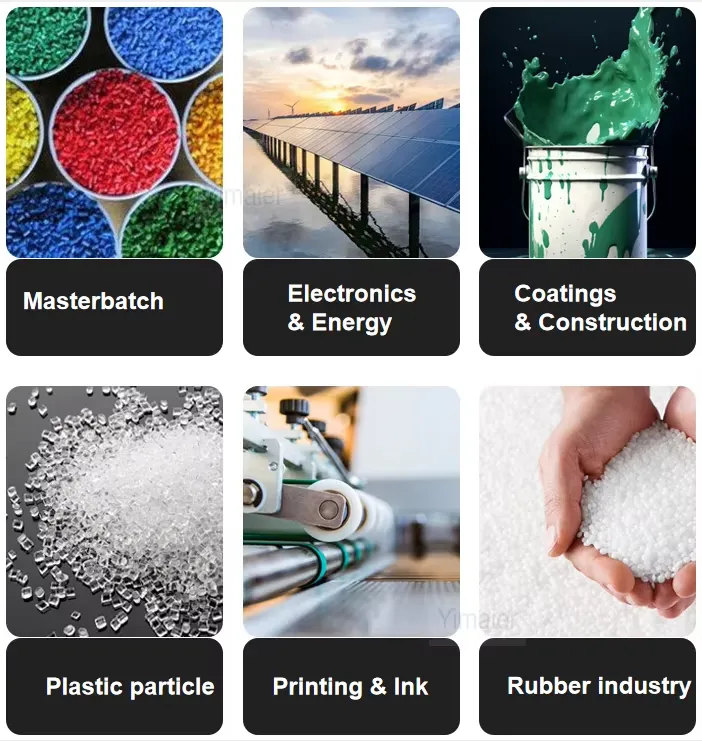

Titanium dioxide (TiO2) is a critical material widely used in various industries, especially in pigments, coatings, plastics, and even in the environmental sector for photocatalytic applications. Among the several forms of titanium oxide, rutile is particularly significant due to its superior properties, including high refractive index, excellent UV resistance, and durability. Consequently, the establishment and operation of titanium oxide rutile factories have become an essential facet of modern industrial development.

Rutile, the most stable and abundant mineral form of titanium dioxide, is predominantly sourced from the mineral sands through extensive mining and refining processes. Factories specializing in the production of rutile titanium oxide focus on utilizing advanced extraction and purification technologies to ensure high-quality output. These factories employ state-of-the-art equipment and methodologies to keep up with the increasing global demand for titanium dioxide, which has seen significant growth due to its wide range of applications.

The manufacturing process of titanium dioxide rutile in factories involves several critical stages, beginning with the mining of raw materials. After extraction, the ore is subjected to various processes, such as crushing, grinding, and separation to obtain the desired rutile concentrate. Subsequently, the concentrate undergoes a series of chemical treatments to produce high-purity titanium dioxide. High-temperature treatment processes, such as the chloride or sulfate routes, are commonly adopted to achieve superior quality specifications required for end-user applications.

titanium oxide rutile factories

Environmental considerations are pivotal in the operation of titanium oxide rutile factories. As the industry faces scrutiny over its ecological footprint, many factories have embraced sustainable practices. This includes waste recycling, water conservation, and minimizing harmful emissions through advanced filtration and treatment systems. Compliance with strict environmental regulations not only helps in preserving the ecosystem but also enhances the reputation and marketability of the products manufactured.

The economic impact of titanium oxide rutile factories extends beyond their immediate contributions to production. They create job opportunities, revitalize local economies, and foster advancements in technological innovation. As countries aim to bolster their manufacturing capabilities, the establishment of these factories serves as a strategic investment in industrial growth.

Importantly, the future of titanium oxide rutile factories looks promising. With the global shift towards sustainability and the increasing demand for eco-friendly products, rutile titanium dioxide is poised to play a vital role. Industries are exploring its potential in fields such as renewable energy and advanced materials, thereby boosting the need for efficient and innovative manufacturing solutions.

In summary, titanium oxide rutile factories represent a crucial component of modern industrial landscapes. They not only cater to diverse market needs but also promote sustainable practices in manufacturing. As technology advances and environmental concerns grow, the importance of these factories will undoubtedly rise, paving the way for a more sustainable and innovative future.

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025