វិច្ឆិកា . 13, 2024 13:05 Back to list

titanium dioxide used in plastic factories

The Application of Titanium Dioxide in Plastic Manufacturing

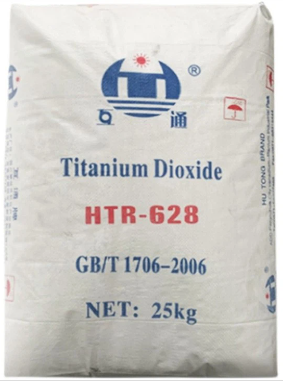

Titanium dioxide (TiO₂) is widely recognized as one of the most versatile and effective materials used in various industries, and its application in plastic manufacturing is particularly noteworthy. As a premium white pigment, TiO₂ is celebrated for its excellent opacity, brightness, and UV resistance, making it an indispensable component in the production of high-quality plastic products ranging from containers to automotive parts. This article explores the significance of titanium dioxide in plastic factories, delving into its benefits, applications, and environmental considerations.

Enhancing Aesthetic and Functional Properties

One of the primary uses of titanium dioxide in plastic manufacturing is to enhance the aesthetic quality of plastic products. The pigment's high refractive index allows it to scatter light effectively, contributing to the bright whiteness that consumers often expect in finished goods. This is particularly important for products requiring a pristine appearance, such as packaging materials, household goods, and consumer electronics.

Moreover, TiO₂ not only improves the aesthetic appeal but also increases the opacity of the plastic, preventing the underlying substrate from showing through. In applications such as paint and coatings, where coverage is crucial, the presence of titanium dioxide ensures that the final product maintains uniformity and quality. Additionally, TiO₂ provides UV resistance, helping to protect plastics from degradation due to sun exposure. This is especially beneficial for outdoor products, which must withstand varied weather conditions and prolonged sunlight.

Wide Range of Applications

The versatility of titanium dioxide allows for its incorporation into a wide range of plastic products. In the packaging industry, TiO₂ is commonly used in food packaging materials to enhance whiteness and protect contents from light degradation, thus prolonging shelf life. In consumer goods, it is a prevalent additive in toys, containers, and household items, ensuring that these products meet consumer expectations for both appearance and durability.

titanium dioxide used in plastic factories

In the automotive sector, where high-performance materials are crucial, titanium dioxide is utilized in various components for its strength and longevity. Interior parts often use TiO₂ to achieve the desired aesthetic while ensuring they can withstand the rigors of daily use. Additionally, in the electrical and electronics industry, titanium dioxide’s dielectric properties enable its use in insulating materials, where it plays a key role in maintaining the safety and reliability of electronic devices.

Environmental Considerations and Sustainability

While titanium dioxide is an invaluable asset in plastic manufacturing, its use comes with environmental considerations. The production and disposal of plastic products can have detrimental effects on the environment. As such, plastic manufacturers are increasingly under pressure to adopt sustainable practices. Many companies are exploring ways to reduce their dependence on virgin materials and invest in recycling initiatives to minimize environmental impact.

To address these concerns, some manufacturers are developing bio-based plastics that incorporate TiO₂ while being more environmentally friendly. These innovative materials aim to reduce reliance on fossil fuels and improve biodegradability. Additionally, ongoing research into the recycling of plastic containing titanium dioxide is essential for creating a circular economy, ensuring that the benefits of TiO₂ can be realized without compromising environmental integrity.

Conclusion

Titanium dioxide plays a pivotal role in the plastic manufacturing industry, enhancing both the aesthetic and functional properties of a myriad of products. Its versatility allows for diverse applications across various sectors while contributing to the quality and durability that consumers expect. As the industry moves towards more sustainable practices, the continued use of TiO₂ will require innovation to ensure that it aligns with environmental goals. By leveraging the benefits of titanium dioxide responsibly, plastic factories can produce high-quality products while contributing to a sustainable future. The future of titanium dioxide in plastics is promising, provided that environmental considerations remain at the forefront of production methodologies.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025