ធ្នូ . 17, 2024 13:59 Back to list

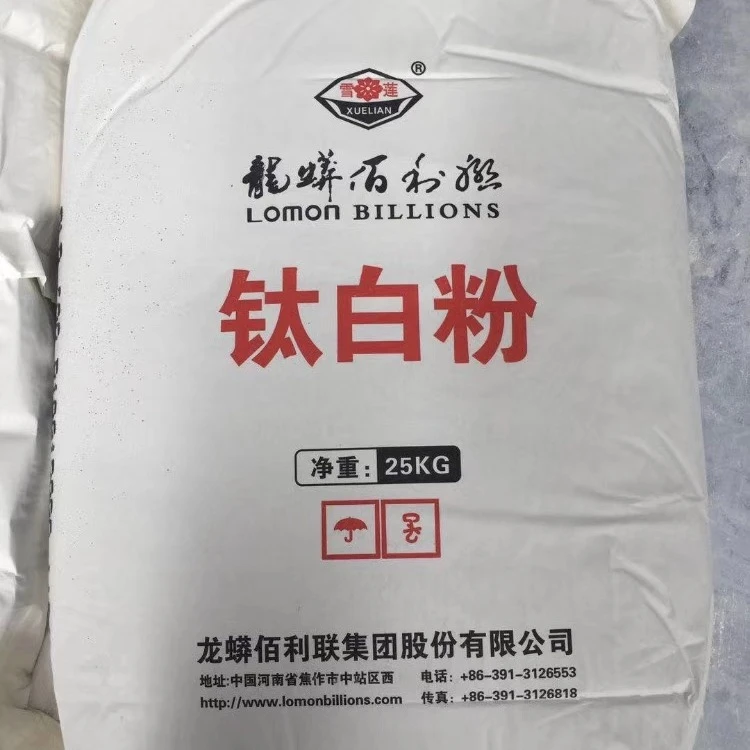

Factories Producing Ultra White Paint with High-Quality Titanium Dioxide for Superior Coverage

The Revolution of Titanium Dioxide Ultra White Paint in Industrial Applications

In the world of coatings and finishes, the demand for high-quality products is continuously growing. Among the various options available, titanium dioxide ultra white paint stands out due to its exceptional properties and versatility. This article explores the significance of titanium dioxide in paint manufacturing, the benefits it offers, and the role of factories in producing this essential material.

Understanding Titanium Dioxide

Titanium dioxide (TiO2) is a naturally occurring mineral that has earned its reputation as one of the most effective white pigments in the industry. Known for its brilliant whiteness and excellent hiding power, TiO2 enhances the brightness and opacity of paints. It is non-toxic, resistant to fading, and provides a long-lasting finish, making it a popular choice in various applications, including residential, commercial, and industrial settings.

The Importance of Ultra White Paint

Ultra white paint, formulated with high-quality titanium dioxide, offers superior reflectivity and durability. This type of paint is particularly valuable in energy-efficient building designs, as it reflects sunlight and helps to maintain cooler indoor temperatures. By reducing reliance on air conditioning, ultra white paint contributes to energy conservation and lowers utility costs. In addition, its reflective properties can minimize the urban heat island effect, making it an environmentally friendly option for urban developments.

Manufacturing Process of Titanium Dioxide Paint

The production of titanium dioxide ultra white paint involves several key steps. Firstly, raw materials are sourced and processed. The titanium dioxide is typically derived from either the sulfate process or the chloride process. The sulfate process uses sulfuric acid to extract TiO2 from ilmenite or rutile, while the chloride process involves converting titanium ore into titanium tetrachloride, which is then oxidized to produce TiO2.

Once the titanium dioxide is synthesized, it is then finely milled and mixed with other components such as binders, solvents, and additives to create the paint formulation. Factors such as particle size, distribution, and surface treatment of titanium dioxide are crucial, as these characteristics significantly impact the final paint's performance.

titanium dioxide ultra white paint factories

The Role of Factories in Production

Factories specializing in titanium dioxide ultra white paint play a critical role in ensuring consistent quality and supply. These facilities are equipped with advanced technology and adhere to stringent quality control measures to guarantee that the final product meets industry standards. Furthermore, many manufacturers are implementing sustainable practices to minimize their environmental footprint, such as recycling waste materials and reducing energy consumption during the production process.

With a growing demand for eco-friendly products, factories are increasingly focusing on producing water-based paints with titanium dioxide. Water-based paints generally have lower levels of volatile organic compounds (VOCs), making them a healthier choice for both consumers and the environment.

Market Trends and Future Outlook

The market for titanium dioxide ultra white paint is experiencing significant growth, driven by expanding applications in construction, automotive, and industrial sectors. The increasing focus on sustainability and energy efficiency is further propelling the demand for high-performance, reflective coatings. As regulations surrounding VOC emissions become more stringent, the shift towards water-based formulations is expected to gain momentum, positioning manufacturers to innovate and meet evolving consumer demands.

Moreover, ongoing research into enhancing the properties of titanium dioxide, such as improving its efficacy in reducing heat absorption, could lead to even greater advancements in ultra white paint technology. The development of nanotechnology may also pave the way for superior formulations that surpass current limitations.

Conclusion

Titanium dioxide ultra white paint represents a significant advancement in the coatings industry. Its remarkable attributes, combined with the commitment of factories to produce high-quality and sustainable products, make it an ideal choice for a variety of applications. As consumers and industries alike become more environmentally conscious, the future of titanium dioxide ultra white paint looks bright, paving the way for innovative solutions in the world of coatings. Through continuous research and development, the potential for titanium dioxide paints to contribute to energy efficiency and sustainability will only continue to grow, marking it as a cornerstone of modern industrial practices.

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025