វិច្ឆិកា . 18, 2024 23:34 Back to list

titanium dioxide for plastic manufacturers

The Role of Titanium Dioxide in Plastic Manufacturing

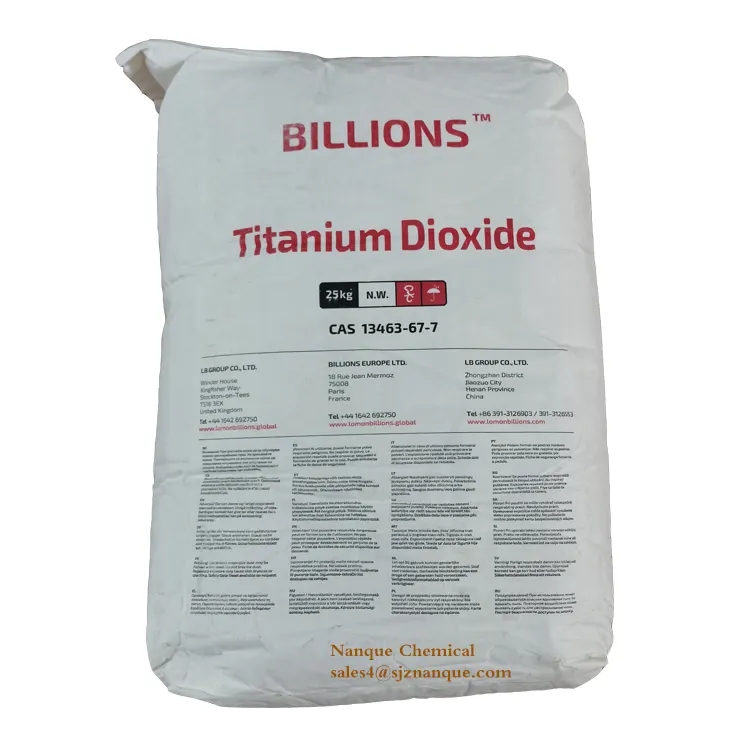

Titanium dioxide (TiO2) is a naturally occurring mineral widely recognized for its exceptional properties and versatility. It plays a pivotal role in the plastic manufacturing industry, mainly due to its effectiveness as a pigment and its unique functional attributes. This article explores the significance of titanium dioxide for plastic manufacturers, examining its benefits, applications, and the ongoing developments in this field.

The Importance of Titanium Dioxide in Plastics

One of the key reasons titanium dioxide is favored in the plastic industry is its outstanding whiteness and opacity. These characteristics make it an ideal white pigment, which is essential for a wide range of plastic products. When incorporated into plastics, TiO2 enhances the brightness and coverage of the final products, ensuring they meet aesthetic and functional requirements.

Moreover, titanium dioxide exhibits excellent UV resistance. This property is particularly important for outdoor applications where plastics are exposed to sunlight. TiO2 provides a protective barrier against harmful UV rays, which can cause degradation, discoloration, and loss of mechanical properties in plastic materials over time. As a result, plastics enhanced with titanium dioxide can maintain their appearance and integrity, leading to longer-lasting products.

Applications of Titanium Dioxide in Plastics

Titanium dioxide finds a wide range of applications in the plastic manufacturing process. It is commonly used in polyethylene, polypropylene, polyvinyl chloride (PVC), polystyrene, and engineering plastics. These materials are prevalent in various industries, including automotive, packaging, construction, and consumer goods.

1. Packaging In the packaging industry, titanium dioxide serves both functional and aesthetic purposes. It enhances the opacity of plastic films and containers, ensuring products remain visible yet protected from light exposure, which can compromise the quality of contents, particularly in food and pharmaceutical applications.

2. Automotive In the automotive sector, TiO2 is incorporated into interior and exterior components to enhance durability and provide color stability. The ability of this pigment to withstand high temperatures and UV exposure makes it particularly suitable for automotive parts that are subject to rigorous conditions.

titanium dioxide for plastic manufacturers

3. Consumer Goods Many household products, including toys, appliances, and furniture, leverage titanium dioxide for its aesthetic appeal and long-lasting qualities. The bright, white finish provided by TiO2 improves product visibility on store shelves and reflects consumer preferences for high-quality, durable goods.

Environmental Considerations

As the demand for sustainable practices increases, manufacturers are seeking eco-friendly alternatives. Titanium dioxide, being a naturally occurring substance, poses relatively low environmental risks when sourced responsibly. However, the production process must adhere to stringent regulations to minimize ecological impacts. Innovations aimed at enhancing the sustainability of titanium dioxide production are underway, focusing on reducing carbon footprints and waste.

Additionally, TiO2 has been recognized for its potential in photocatalytic applications. In this context, it can be utilized to break down pollutants and contribute to cleaner environments when incorporated into certain plastic products. This dual function adds significant value to manufacturers looking to enhance their sustainability credentials.

Challenges and Future Prospects

Despite its numerous advantages, titanium dioxide is not without challenges. Regulatory scrutiny regarding the safety of certain forms of TiO2, especially in aerosolized applications, has prompted manufacturers to re-evaluate their use. The industry is responding by investing in research to develop safer alternatives and improve existing formulations.

Looking ahead, the future of titanium dioxide in the plastic manufacturing industry appears bright. With ongoing advancements in technology and a growing emphasis on sustainability, plastic manufacturers can continue to leverage the benefits of TiO2 while aligning with global environmental goals. As innovations emerge, it is expected that titanium dioxide will play an even more integral role in advancing the quality, longevity, and sustainability of plastic products.

Conclusion

In conclusion, titanium dioxide is a cornerstone of the plastic manufacturing industry, providing critical benefits that enhance both the performance and aesthetics of plastic products. As manufacturers navigate the complexities of sustainability and safety, the versatility of titanium dioxide ensures it remains a valuable asset in the ever-evolving landscape of plastics. With continued innovation and responsible sourcing practices, titanium dioxide will undoubtedly maintain its prominence in the industry for years to come.

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025