វិច្ឆិកា . 10, 2024 21:05 Back to list

Titanium Dioxide Applications in Plastic Manufacturing and Its Benefits for Factories

Titanium Dioxide in Plastic Manufacturing An Essential Ingredient

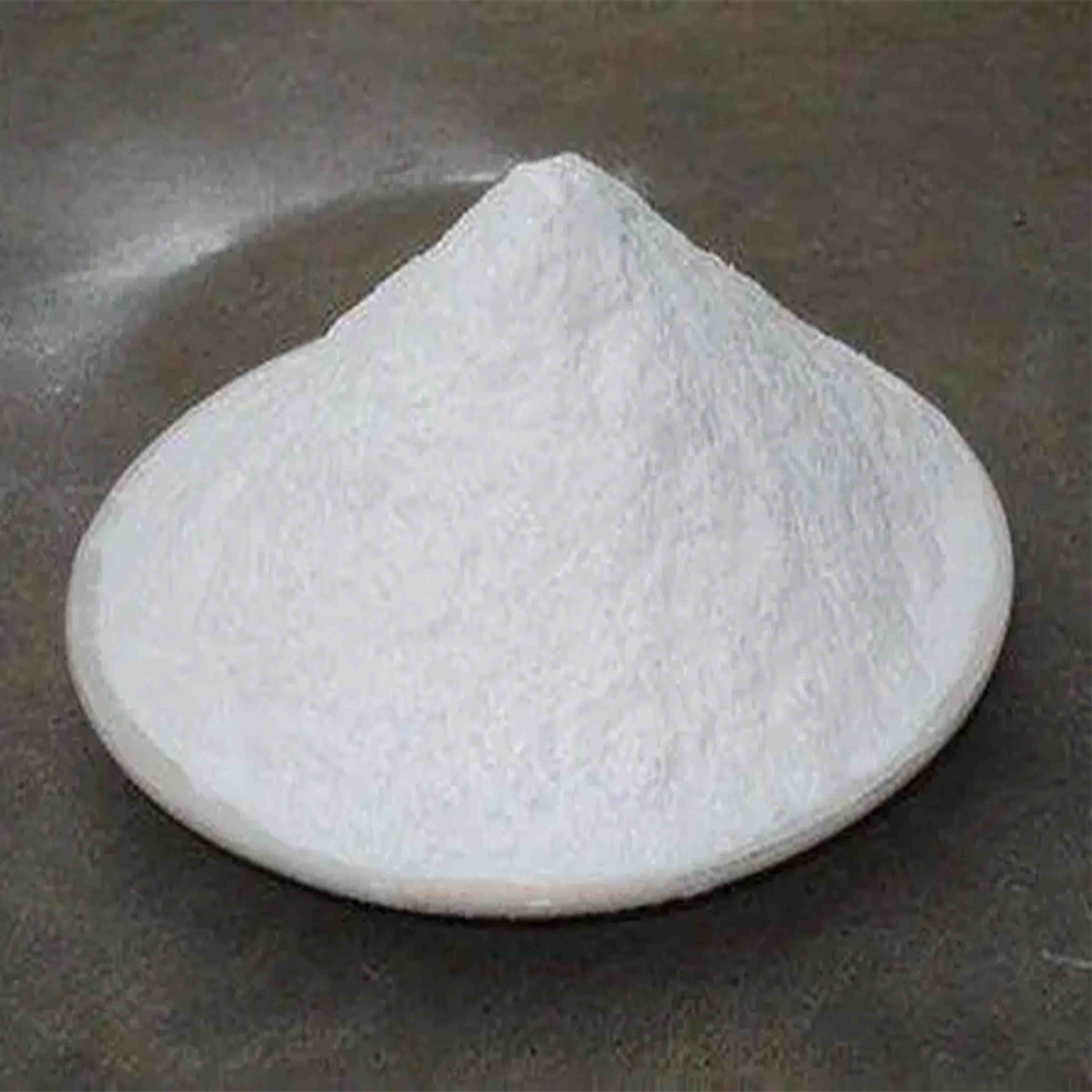

Titanium dioxide (TiO2) is a widely used white pigment that plays a critical role in various industries, particularly in plastic manufacturing. Its unique properties, such as high refractive index, excellent opacity, and durability, make it an invaluable component in the production of plastics used for various applications, ranging from packaging materials to automotive components.

Understanding Titanium Dioxide

Titanium dioxide is a naturally occurring oxide of titanium that is derived from two primary minerals rutile and anatase. It can be produced through two main processes the sulfate process and the chloride process. The sulfate process involves the reaction of titanium ore with sulfuric acid, while the chloride process uses chlorine to produce titanium tetrachloride, which is then oxidized to form TiO2. Among these, the chloride process is known for producing higher-quality titanium dioxide with superior brightness and opacity.

Role in Plastic Manufacturing

In plastic manufacturing, titanium dioxide serves several essential purposes

1. Pigmentation The most significant role of titanium dioxide in plastic products is its function as a pigment. It provides the white color and enhances the brightness of plastic materials. This property is essential for producing items where color accuracy and brightness are crucial, such as consumer goods, toys, and household products.

2. Opacity and UV Protection Titanium dioxide offers excellent opacity, allowing manufacturers to create opaque products that hide imperfections or undesirable colors in the underlying plastic substrate. Additionally, TiO2 has the ability to absorb ultraviolet (UV) radiation, helping to protect plastic products from degradation caused by sun exposure. This is particularly beneficial for outdoor applications, where plastics are frequently subjected to harsh environmental conditions.

titanium dioxide for plastic factories

3. Durability and Weather Resistance The incorporation of titanium dioxide in plastics enhances their mechanical properties, contributing to improved durability and weather resistance. This is essential for products that need to withstand extreme temperatures, moisture, and UV light over prolonged periods.

4. Versatility in Applications Titanium dioxide is used across a wide range of plastic applications, including polyvinyl chloride (PVC), polyethylene, polypropylene, and polystyrene. Its versatility allows manufacturers to cater to different consumer needs, from food packaging to construction materials.

Health and Safety Considerations

While titanium dioxide is generally regarded as safe for use in various applications, recent regulatory discussions have raised questions about its potential health effects, particularly in inhalable forms. The International Agency for Research on Cancer (IARC) classified titanium dioxide as possibly carcinogenic to humans when inhaled in large quantities, leading to increased scrutiny by regulatory bodies. As a result, it is essential for manufacturers to follow strict guidelines pertaining to occupational safety and health when using TiO2 in powdered form to minimize inhalation risks.

Sustainability and Innovation

As the world becomes more environment-conscious, the plastics industry is exploring sustainable alternatives and innovative solutions involving titanium dioxide. Researchers are developing biodegradable plastic composites that incorporate TiO2, aiming to enhance their properties while reducing environmental impact. The potential use of recycled TiO2 from end-of-life products is also being investigated, contributing to a circular economy and minimizing waste.

Conclusion

Titanium dioxide is a crucial component of plastic manufacturing, contributing to the aesthetics, durability, and performance of plastic products. As industries evolve, the focus will undoubtedly shift towards safer, more sustainable use of TiO2. By leveraging technology and innovation, manufacturers can continue to utilize this remarkable pigment while adhering to health and environmental standards. In an ever-changing global landscape, the importance of titanium dioxide in plastics cannot be overstated, making it an essential topic for further research and development.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025