ធ្នូ . 14, 2024 07:48 Back to list

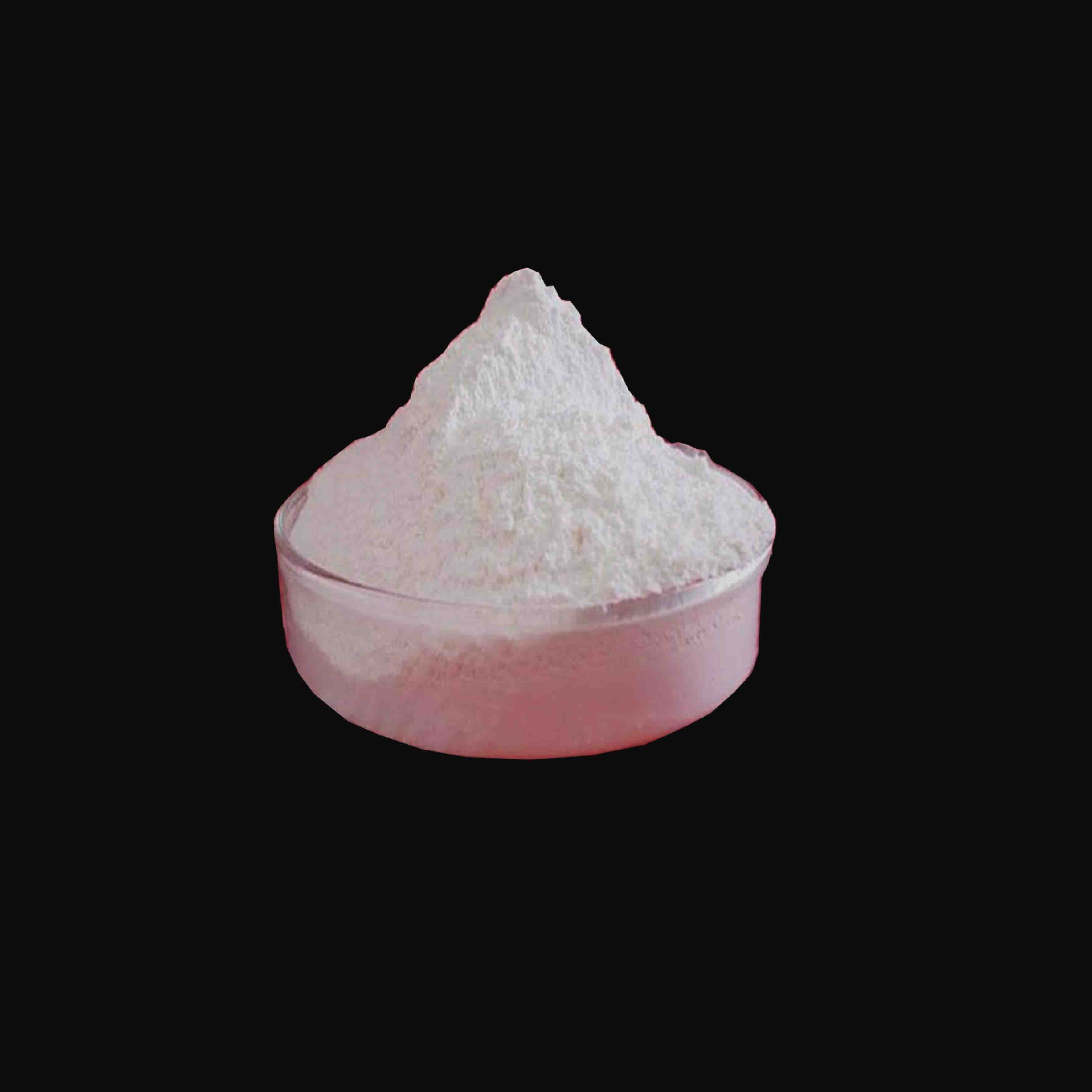

Chloride Process Titanium Dioxide BLR-895 for Automotive Coatings and Refinishing Applications

Titanium Dioxide BLR-895 A Game Changer for Automotive OEM and Refinishing Coatings

In the automotive industry, achieving the perfect balance of durability, aesthetic appeal, and environmental compliance is crucial. One of the most significant advancements in this domain has been the development of advanced titanium dioxide (TiO2) pigments, particularly the BLR-895 grade, manufactured through the chloride process. This article explores the benefits and applications of Titanium Dioxide BLR-895 in automotive Original Equipment Manufacturer (OEM) coatings and refinishing coatings.

Understanding Titanium Dioxide BLR-895

Titanium dioxide is renowned for its excellent opacity, brightness, and UV resistance properties. The BLR-895 variant stands out because of its unique production process. The chloride process, utilized to create this premium pigment, involves a cleaner and more efficient method of synthesizing titanium dioxide compared to the older sulfate method. This results in a pigment with superior purity, a finer particle size distribution, and enhanced performance characteristics.

Advantages for Automotive OEM Coatings

1. Superior Color Performance Automotive manufacturers seek coatings that not only provide protection but also enhance the visual appeal of the vehicle. BLR-895 offers exceptional color strength and opacity, enabling manufacturers to achieve vibrant colors even with lower pigment loading. This not only reduces material costs but also enhances the overall sustainability of the automotive production process.

2. Excellent Weather Resistance Vehicles are subjected to various environmental factors, including UV radiation, moisture, and temperature fluctuations. BLR-895 provides outstanding weather resistance, thereby prolonging the lifespan of the coating. This is particularly important in automotive applications, where a durable finish can enhance vehicle resale value by maintaining aesthetics over time.

3. Low VOC and Environmental Compliance With increasing regulations on volatile organic compounds (VOCs), the automotive industry is under pressure to adopt eco-friendly solutions. BLR-895 fits the bill, as it can be formulated into low-VOC coatings without compromising performance. This characteristic is crucial for OEMs looking to comply with environmental regulations while meeting consumer demand for sustainable products.

titanium dioxide blr-895 for automotive oem coatings and refinishing coatings manufactured by chloride process

Benefits for Refinishing Coatings

Refinishing coatings in the automotive sector require different performance characteristics due to their unique applications. Titanium Dioxide BLR-895 meets these requirements effectively

1. High Compatibility Refinishing requires coatings that can seamlessly blend with various substrates, including existing paints. The compatibility of BLR-895 ensures excellent adhesion, which is fundamental for maintaining a uniform appearance in repairs and touch-ups.

2. Quick Drying and Curing Time is of the essence in the automotive refinishing business. The use of BLR-895 in formulations can help accelerate the drying and curing processes, reducing downtime for vehicles in repair. This feature significantly enhances productivity for refinishers.

3. Enhanced Scratch Resistance One of the persistent challenges in automotive refinishing is ensuring that the repaired areas withstand daily wear and tear. BLR-895 contributes to the formulation of finishes that exhibit superior scratch resistance, ensuring that refinished areas maintain their integrity and appearance under real-world conditions.

Conclusion

As the automotive industry evolves, the demand for high-performance, sustainable, and aesthetically pleasing coatings continues to grow. Titanium Dioxide BLR-895, manufactured using the chloride process, emerges as a revolutionary solution for both OEM and refinishing applications. Its superior properties, including vibrant color performance, weather resistance, low VOC content, compatibility, quick curing, and scratch resistance, set it apart as an essential ingredient in modern automotive coatings.

For manufacturers and refinishers alike, investing in high-quality raw materials like BLR-895 is a step toward achieving remarkable results while adhering to environmental standards. In a highly competitive market, such innovations not only enhance the product offerings but also strengthen a brand's commitment to quality and sustainability.

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025

-

High Quality Titanium Dioxide Used in Rubber – Trusted Supplier & Factory Price

NewsJul.08,2025

-

High Purity Barium Sulfate Particle Size - Wholesale Manufacturer from China

NewsJul.07,2025

-

Premium Titanium Dioxide Lomon R-996 Supplier – Quality & Wholesale Price from China

NewsJul.07,2025

-

Top Titanium Manufacturers in China - Quality Titanium Dioxide Supplier & Production Line Solutions

NewsJul.06,2025

-

OEM Titanium White Supplier & Factory – High Purity, Consistent Quality for Industrial Use

NewsJul.06,2025