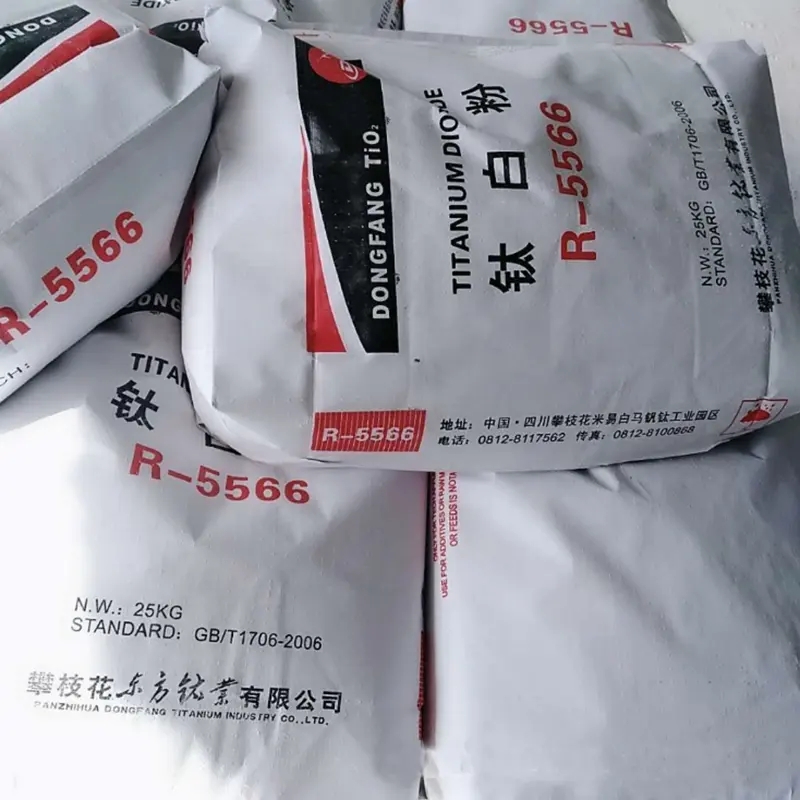

chemical material tio2 rutile titanium dioxide r816 for coating and paints suppliers

កុម្ភៈ . 19, 2025 07:01 Back to list

chemical material tio2 rutile titanium dioxide r816 for coating and paints suppliers

Navigating the intricate realm of suppliers for TiO2 coatings requires a sophisticated understanding of both the product and the industry landscape. Titanium dioxide (TiO2) is renowned for its unparalleled whiteness and opacity, essential for enhancing the performance and aesthetic of coatings in various applications, such as in the architectural, automotive, and industrial sectors.

The level of technical support and expertise a supplier offers can greatly influence a manufacturer’s choice. Suppliers that extend comprehensive client support, including formulation assistance, troubleshooting, and training, stand out. This interaction not only augments the client’s knowledge base but also builds a robust, trustworthy partnership. A notable trend within the TiO2 for coating sector is the push for more efficient use of resources. This includes optimizing TiO2 usage to reduce costs and environmental impact by integrating advanced formulas that provide superior opacity and coverage at lower pigment loadings. Suppliers at the forefront of this innovation, utilizing cutting-edge technologies, often lead the market, offering both cost-effective and environmentally friendly solutions. Furthermore, advancements in TiO2 technology have given rise to new frontiers, such as nano TiO2, which offers unique properties for specialized coating applications, including UV protection and enhanced durability. Assessing a supplier’s portfolio for such technologically advanced options can position manufacturers ahead in competitive markets. Building long-term relationships with TiO2 suppliers can also mitigate risks associated with supply chain disruptions. Suppliers who have demonstrated resilience in fluctuating markets, maintaining steady supply chains and pricing flexibility, provide a significant competitive edge to manufacturers relying on continuous production cycles. In conclusion, the journey to identifying and partnering with a premium TiO2 supplier necessitates a critical evaluation of their market presence, product quality, adherence to regulatory standards, and technical support. With the right supplier, manufacturers not only enhance their products’ performance but also secure a reliable partner dedicated to innovation and sustainability in the ever-evolving coatings industry. The choice of supplier is not just a transactional decision but a strategic partnership integral to the success and competitiveness of coating products in the global market.

The level of technical support and expertise a supplier offers can greatly influence a manufacturer’s choice. Suppliers that extend comprehensive client support, including formulation assistance, troubleshooting, and training, stand out. This interaction not only augments the client’s knowledge base but also builds a robust, trustworthy partnership. A notable trend within the TiO2 for coating sector is the push for more efficient use of resources. This includes optimizing TiO2 usage to reduce costs and environmental impact by integrating advanced formulas that provide superior opacity and coverage at lower pigment loadings. Suppliers at the forefront of this innovation, utilizing cutting-edge technologies, often lead the market, offering both cost-effective and environmentally friendly solutions. Furthermore, advancements in TiO2 technology have given rise to new frontiers, such as nano TiO2, which offers unique properties for specialized coating applications, including UV protection and enhanced durability. Assessing a supplier’s portfolio for such technologically advanced options can position manufacturers ahead in competitive markets. Building long-term relationships with TiO2 suppliers can also mitigate risks associated with supply chain disruptions. Suppliers who have demonstrated resilience in fluctuating markets, maintaining steady supply chains and pricing flexibility, provide a significant competitive edge to manufacturers relying on continuous production cycles. In conclusion, the journey to identifying and partnering with a premium TiO2 supplier necessitates a critical evaluation of their market presence, product quality, adherence to regulatory standards, and technical support. With the right supplier, manufacturers not only enhance their products’ performance but also secure a reliable partner dedicated to innovation and sustainability in the ever-evolving coatings industry. The choice of supplier is not just a transactional decision but a strategic partnership integral to the success and competitiveness of coating products in the global market.

Latest news

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025