ធ្នូ . 21, 2024 06:58 Back to list

lithopone formula factory

The Lithopone Formula Factory An Overview of Production and Applications

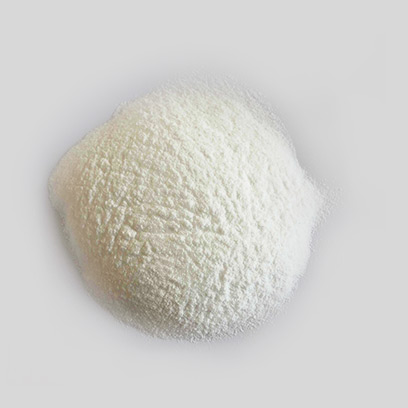

Lithopone is a white pigment made from a mixture of zinc sulfide and barium sulfate, widely recognized for its excellent opacity and brightness. The name “lithopone” derives from the combination of two words “lithos,” meaning stone, and “pon,” an abbreviation of the chemical compound 'zinc sulfide.' First developed in the 19th century, lithopone replaced lead white and became a preferred colorant in various industries due to its non-toxic nature and versatility. This article explores the production process in a lithopone formula factory and its wide-ranging applications.

Production Process

The production of lithopone involves a series of chemical reactions and purification steps. The primary raw materials used in the lithopone manufacturing process are zinc oxide (ZnO), barium sulfide (BaS), and sodium sulfate (Na2SO4).

1. Synthesis of Pigment The first step in the factory involves reacting barium sulfide with sodium sulfate to create barium sulfate. This is typically done in a reactor vessel where the two compounds are combined under controlled temperature and pressure. This reaction results in the precipitation of barium sulfate.

2. Formation of Zinc Sulfide Next, zinc oxide is reacted with hydrogen sulfide gas (H2S) to form zinc sulfide. This step also takes place in a controlled environment to ensure purity and quality of the product. The zinc sulfide precipitate is then collected and washed to remove any impurities.

3. Combining Components Once both barium sulfate and zinc sulfide are prepared, they are carefully combined in specific ratios to ensure optimal performance characteristics. The standard formula comprises about 30% zinc sulfide and 70% barium sulfate.

4. Drying and Milling The combined product is then dried and milled into a fine powder. The fineness of the powder plays a crucial role in the final opacity and brightness of the lithopone pigment. Advanced milling techniques ensure that the particles are evenly sized and homogenous, resulting in a superior product.

5. Quality Control Throughout the production process, quality control measures are put in place to test samples for consistency, brightness, and opacity. Rigorous testing is essential, as the standards for commercial pigments are high, and the colorant must meet specific regulations before it can be sold.

lithopone formula factory

Applications

Lithopone finds a variety of applications across several industries due to its excellent properties

.1. Paints and Coatings One of the most significant uses of lithopone is in the manufacture of paints and coatings. Its high opacity enables it to cover surfaces effectively, providing a bright white base that enhances the appearance of colors painted over it. Lithopone is particularly favored in water-based paint formulations.

2. Plastics Lithopone is used as a filler in plastic products, helping to enhance the color and durability of the materials. It is often employed in PVC plastics and other synthetic surfaces, contributing to improved UV resistance and overall aesthetic appeal.

3. Paper and Ink In the paper industry, lithopone is utilized as a brightening agent. It not only improves the whiteness of the paper but also enhances print quality when used in inks.

4. Cosmetics Due to its non-toxic nature, lithopone is also found in various cosmetic products, including sunscreens and powders, where it provides a white base and aids in UV protection.

5. Construction Materials Finally, lithopone is used in construction materials, like cement and mortar, to improve their whiteness and finish, making them visually appealing for architectural applications.

Conclusion

The lithopone formula factory symbolizes a blend of chemistry and industry, producing a versatile pigment that serves numerous applications. As environmental concerns regarding toxic pigments continue to rise, lithopone offers a safe and effective alternative. Its significance in various sectors highlights the ongoing demand for quality pigments, reinforcing the importance of efficient production methods and quality control in the lithopone manufacturing process. With continued advancements in production techniques, the future of lithopone remains bright, promising innovation and sustainability in the pigment industry.

-

China Lithopone in China Supplier – High Quality Lithopone ZnS 30% Powder for Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Company – Premium TiO2 Powder Supplier & Manufacturer

NewsJun.10,2025

-

Fast Shipping 99% Pure TiO2 Powder CAS 13463-67-7 Bulk Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Manufacturers High-Purity R996 & Anatase

NewsJun.10,2025

-

Lithopone MSDS Factories - Production & Quotes

NewsJun.10,2025

-

High-Quality Titanium Dioxide in Water Suppliers - China Expertise 60

NewsJun.09,2025