ធ្នូ . 14, 2024 07:32 Back to list

lithopone b301 factories

The Production and Applications of Lithopone B301

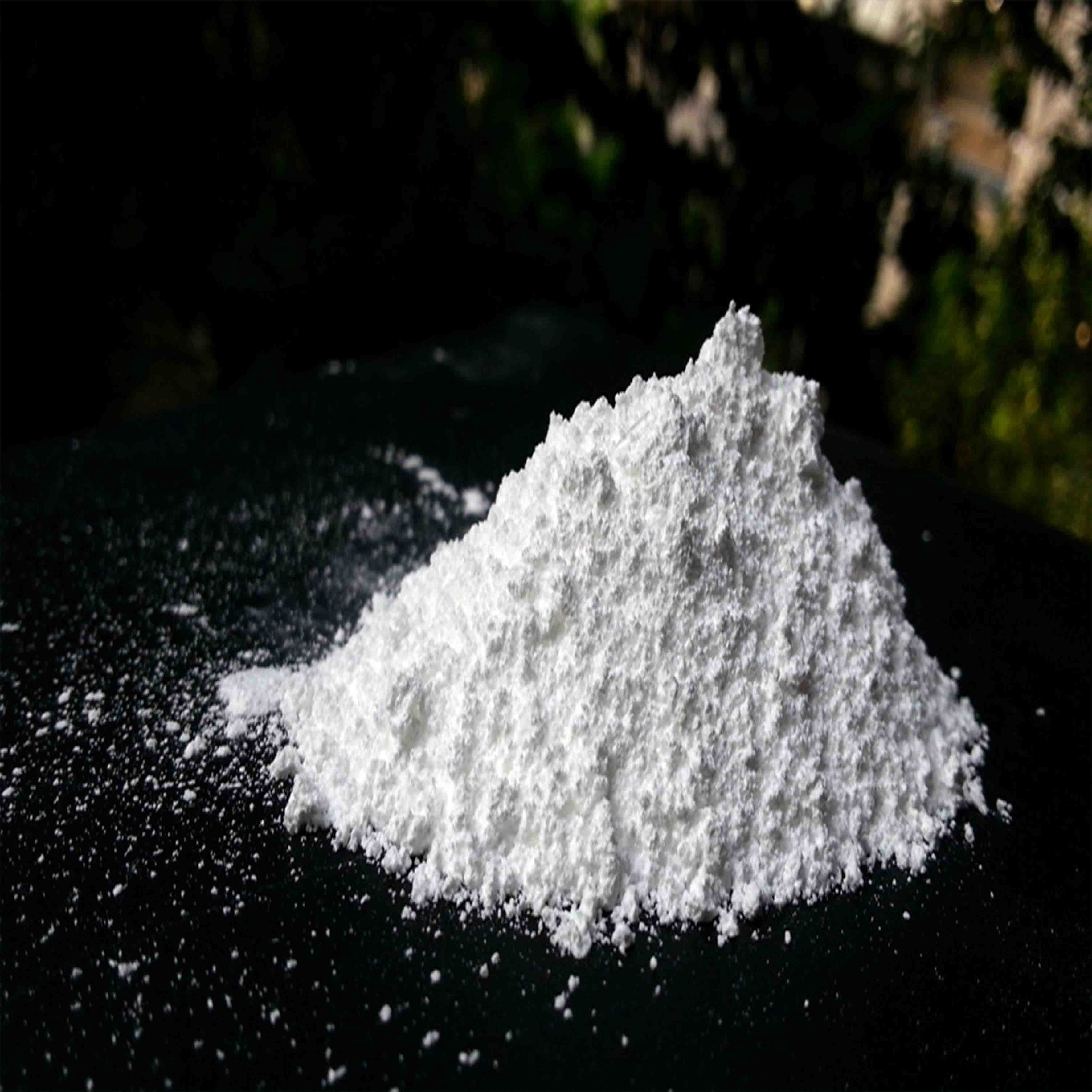

Lithopone B301 is a white pigment known for its excellent opacity, brightness, and versatility, widely used in various industries such as paints, coatings, plastics, and rubber. This compound, a mixture of zinc sulfide and barium sulfate, is primarily produced through a chemical process that combines elements of both metals. The unique properties of Lithopone B301 make it a favored choice among manufacturers aiming for high-quality finishes while maintaining cost-effectiveness.

Manufacturing Process of Lithopone B301

The production of Lithopone B301 typically involves a series of chemical reactions. The initial stage consists of precipitating zinc sulfide from zinc salts and sodium sulfide. Once the zinc sulfide is produced, barium sulfate is introduced to create the final product. This reaction is critical, as the right conditions must be met to ensure a high level of purity and quality in the final pigment.

Control over the production environment—such as temperature, pH levels, and the purity of raw materials—is essential. The use of advanced technology in factories allows for precise control over these parameters, leading to a consistent and reliable product. Moreover, modern manufacturing processes are designed to minimize waste and energy consumption, addressing environmental concerns associated with industrial production.

Quality Control and Standards

Once Lithopone B301 is produced, rigorous quality control measures are implemented. These measures ensure that the pigment meets industry standards concerning purity, particle size, and opacity. Factories dedicated to the production of Lithopone B301 often employ advanced testing methods, including spectroscopy and microscopy, to analyze the pigment for any impurities or irregularities.

Adhering to international standards, factories producing Lithopone B301 must also comply with environmental regulations. The production process is scrutinized to ensure that waste materials and emissions are managed properly, highlighting the importance of sustainable manufacturing practices in the industry.

lithopone b301 factories

Applications of Lithopone B301

The versatility of Lithopone B301 allows it to be used in a wide range of applications. Its primary use is as a pigment in the paint and coating industry, where it imparts a bright white color and excellent hiding power. Lithopone B301 is particularly valued for its ability to be mixed with other pigments, enhancing the overall opacity and brightness of the paint while maintaining a smooth texture.

In the plastics industry, Lithopone B301 serves as a filler and a colorant, providing not only aesthetic qualities but also improving mechanical properties. Its use in rubber products enhances durability, making Lithopone B301 a common choice for manufacturers of tires and other rubber goods.

Furthermore, Lithopone B301 finds relevance in the cosmetic industry, where it is utilized in products such as sunscreens and makeup. Its non-toxic nature and excellent coverage make it an appealing option for formulations that require a white base or high opacity.

The Market for Lithopone B301

The demand for Lithopone B301 has been steadily growing, driven by the expansion of industries that utilize this pigment. Market trends indicate a shift towards sustainable and environmentally friendly products, pushing factories to innovate in terms of production methods. As consumers become more informed about the environmental impact of industrial processes, manufacturers are prompted to adopt greener practices to meet market demands.

In conclusion, Lithopone B301 continues to play a significant role in various industries, thanks to its favorable properties and adaptability. As factories around the world strive to enhance their production processes and product quality, the future of Lithopone B301 looks promising. With ongoing research and development, it is likely that new applications for this versatile pigment will emerge, further solidifying its place in the global market. The combination of traditional manufacturing expertise with modern technological advancements is shaping a compelling narrative for the continued relevance of Lithopone B301 in an ever-evolving industrial landscape.

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025

-

High Quality Titanium Dioxide Used in Rubber – Trusted Supplier & Factory Price

NewsJul.08,2025

-

High Purity Barium Sulfate Particle Size - Wholesale Manufacturer from China

NewsJul.07,2025

-

Premium Titanium Dioxide Lomon R-996 Supplier – Quality & Wholesale Price from China

NewsJul.07,2025

-

Top Titanium Manufacturers in China - Quality Titanium Dioxide Supplier & Production Line Solutions

NewsJul.06,2025

-

OEM Titanium White Supplier & Factory – High Purity, Consistent Quality for Industrial Use

NewsJul.06,2025