កញ្ញា . 06, 2024 18:03 Back to list

Leading Manufacturer of Titanium Dioxide (TiO2) - Quality Factory Sales

Exploring the Dynamics of Factory Sales in the TiO2 Manufacturing Industry

Titanium dioxide (TiO2) is a widely used pigment that plays a crucial role in various industries, including paints, plastics, paper, and cosmetics. As the demand for high-quality TiO2 continues to grow globally, the factory sales of TiO2 manufacturers have become increasingly important. This article delves into the dynamics of factory sales in the TiO2 manufacturing sector, highlighting key trends, challenges, and future prospects.

The TiO2 market has witnessed significant growth over the past few years, driven by the rapid expansion of industries requiring this versatile pigment. The construction and automotive sectors, in particular, have contributed to the rising demand for TiO2. As the global population continues to grow, particularly in developing regions, the need for infrastructure development and consumer goods is expected to increase, further boosting the TiO2 market.

Exploring the Dynamics of Factory Sales in the TiO2 Manufacturing Industry

In terms of sales strategies, TiO2 manufacturers are increasingly leveraging digital marketing and e-commerce platforms to reach a broader customer base. Direct factory sales enable manufacturers to establish closer relationships with their clients, providing them with tailored solutions and improving customer satisfaction. This approach also allows manufacturers to maintain competitive pricing by cutting out intermediaries.

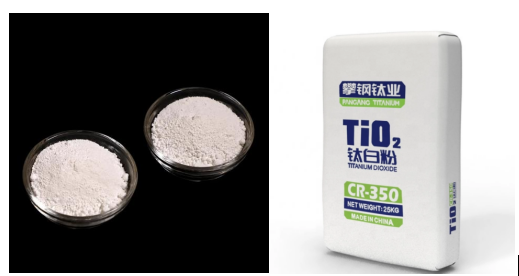

factory sales tio2 manufacturer

However, the TiO2 manufacturing sector is not without its challenges. Fluctuating raw material prices and stringent environmental regulations pose significant hurdles for manufacturers. The production of TiO2 often involves the use of hazardous materials, leading to increased scrutiny from regulatory bodies. Ensuring compliance with these regulations requires substantial investments in waste management and pollution control technologies.

Furthermore, the global market for TiO2 is affected by geopolitical factors and trade policies. Tariffs and trade restrictions in certain regions can impact the accessibility of raw materials and limit market opportunities for manufacturers. To navigate these challenges, TiO2 manufacturers must adopt agile strategies, diversifying their supply chains and markets to mitigate risks.

Looking ahead, the future of factory sales in the TiO2 manufacturing industry appears promising. With the ongoing innovation in production technologies and growing emphasis on sustainability, manufacturers are well-positioned to meet the evolving needs of their customers. Additionally, as industries shift towards environmentally friendly products, there will likely be an increased demand for high-performance TiO2 with reduced environmental impact.

In conclusion, factory sales play a vital role in the TiO2 manufacturing sector, driving growth and innovation. By embracing new technologies and adapting to market changes, TiO2 manufacturers can capitalize on emerging opportunities while addressing the challenges they face. As they continue to evolve, these manufacturers will remain essential players in the supply chain, supporting various industries worldwide.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025