វិច្ឆិកា . 19, 2024 01:13 Back to list

Titanium Dioxide CAS 13463-67-7 Production Overview and Factory Insights

An Insight into Titanium Dioxide (CAS 13463-67-7) Production Factory Operations and Applications

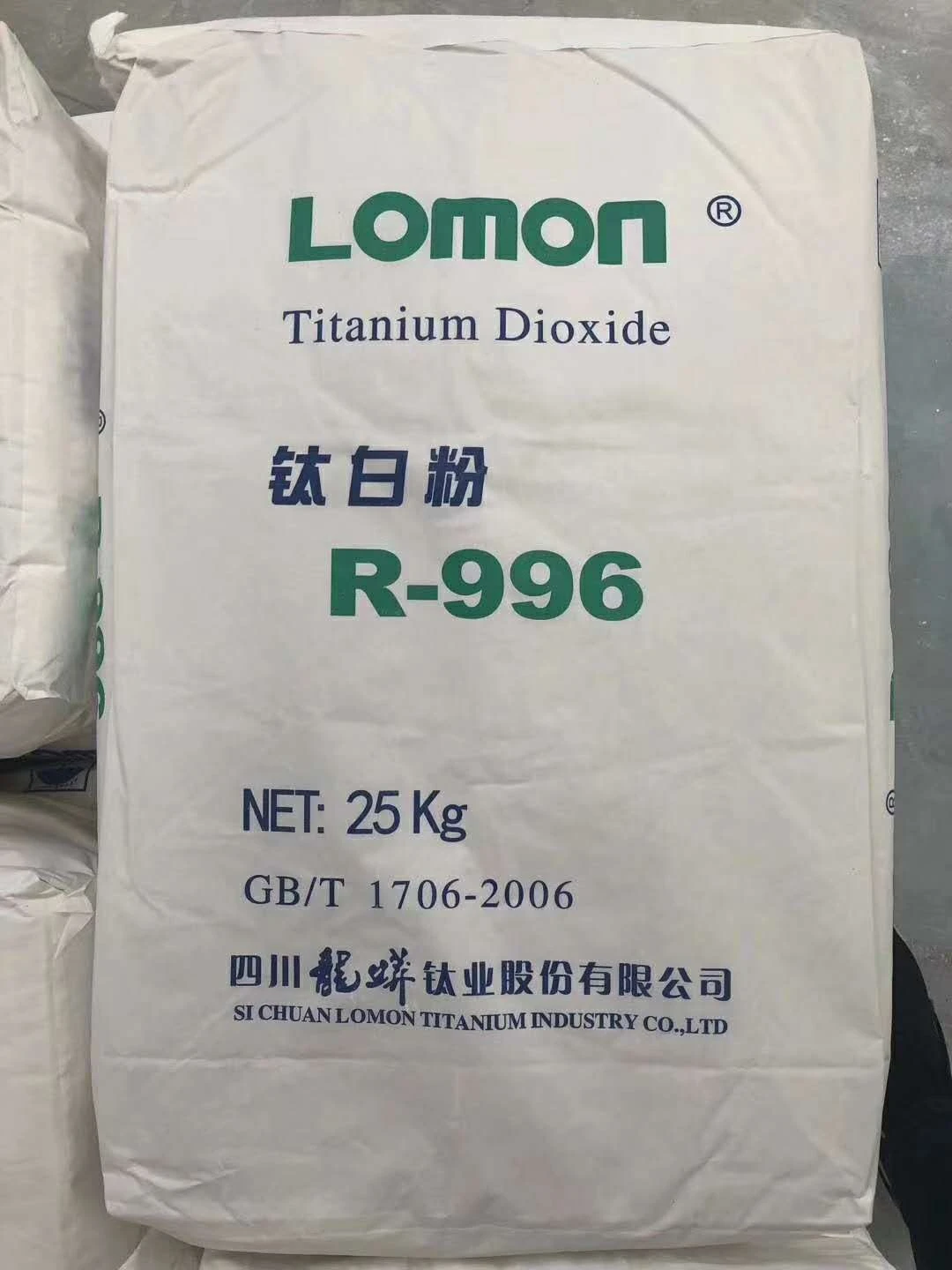

Titanium dioxide, commonly referred to by its chemical formula TiO2 and recognized by its CAS number 13463-67-7, is a widely used inorganic compound renowned for its excellent pigmentary properties and versatility in various industrial applications. This white pigment, known for its brightness and high refractive index, is predominantly used in paints, coatings, plastics, paper, and cosmetics. Understanding the production processes within a titanium dioxide factory is imperative for grasping its crucial role in multiple sectors.

Production Processes

Titanium dioxide can be produced through two primary methods the sulfate process and the chloride process. Each method has its advantages and is suitable for specific applications, resulting in different grades of TiO2.

1. Sulfate Process The sulfate process involves the digestion of titanium ores (such as ilmenite) in sulfuric acid. This method generates a slurry that undergoes filtration to separate impurities. After purification, the titanyl sulfate produced is hydrolyzed to form titanium dioxide. It is then calcined at high temperatures to produce high-quality TiO2. The sulfate process typically yields a lower-cost product but is associated with higher waste generation and environmental concerns.

2. Chloride Process The chloride process employs chlorine gas to convert titanium ores into titanium tetrachloride (TiCl4). This gaseous intermediate is subsequently oxidized in a high-temperature reactor, producing titanium dioxide. This method is favored for its ability to produce high-purity titanium dioxide and lower environmental impact compared to the sulfate process. Products derived from the chloride process often possess superior whiteness and better performance in applications.

Factory Operations

The operations within a titanium dioxide factory are multifaceted, involving various stages of production ranging from raw material sourcing to quality control. Here’s a breakdown of these operations

- Raw Material Sourcing The primary raw materials, titanium ores, are sourced from mineral deposits. Factories often establish long-term relationships with suppliers to ensure the consistent quality and quantity of materials.

dioxide titanium cas 13463-67-7 factory

- Processing Facilities High-capacity reactors and processing units are utilized for both the sulfate and chloride processes. These facilities are equipped with advanced technology to monitor and manage temperature, pressure, and chemical reactions efficiently.

- Environmental Management Given the potential environmental impacts associated with titanium dioxide production, factories are increasingly adopting sustainable practices. This includes waste management protocols, emissions control systems, and water recycling technologies that minimize their ecological footprint.

- Quality Control Rigorous quality control measures are implemented throughout the production process. Samples of TiO2 are regularly analyzed for purity, particle size, and color strength to ensure compliance with international standards.

Applications and Market Trends

Titanium dioxide's versatility translates into its extensive use across various industries. In the paint and coatings industry, TiO2 acts as a pigment that provides opacity and brightness. In plastics, it enhances durability and UV resistance, making it an integral additive. The cosmetic industry relies on TiO2 for its ability to offer a white base and its reflective properties in sunscreens.

In recent years, the demand for titanium dioxide has surged due to the growth in construction, automotive, and consumer goods sectors. Moreover, the push for sustainable products has led to innovative applications, such as in photocatalysis and self-cleaning surfaces, where TiO2 plays a pivotal role in driving advancements in technology.

Conclusion

The production of titanium dioxide, especially through processes associated with the CAS number 13463-67-7, is critical to numerous industrial applications. As factories strive to enhance efficiency and minimize their environmental impact, they are also adapting to the evolving demands of the global market. The continued innovation in production techniques and applications will likely define the future trajectory of titanium dioxide, solidifying its place as a vital component in everyday products. Understanding these factory operations offers valuable insight into an industry that significantly affects our modern life and the environment.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025