ធ្នូ . 24, 2024 04:43 Back to list

competitive price rutile titanium dioxide suppliers

Understanding Competitive Pricing for Rutile Titanium Dioxide Suppliers

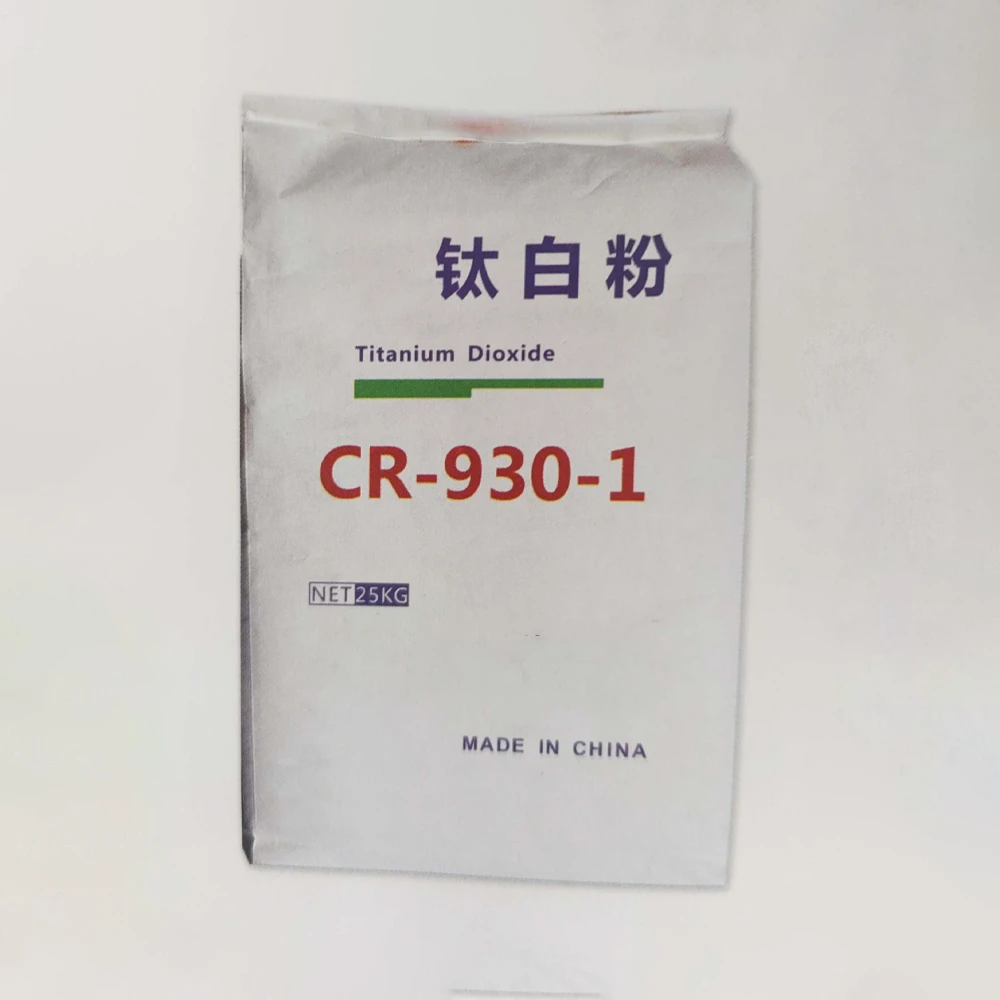

In the realm of industrial minerals, rutile titanium dioxide (TiO2) stands out as one of the most sought-after compounds. Renowned for its exceptional whiteness, opacity, and UV resistance, rutile TiO2 is widely employed in various applications including paints, coatings, plastics, paper, and even cosmetics. Its importance in modern manufacturing cannot be overstated, and as a result, suppliers are continuously looking for ways to offer competitive prices to meet growing demands.

The Market Landscape

The rutile titanium dioxide market is characterized by a blend of established producers and emerging suppliers. Major players dominate the landscape, leveraging economies of scale to produce TiO2 at lower costs. However, the competition is fierce, as new entrants seek to carve out a niche market by offering innovative products or services. Suppliers must not only focus on pricing but also on quality and sustainability to differentiate themselves in such a competitive environment.

The price of rutile TiO2 is driven by several factors extraction costs, production technologies, raw material availability, and regulatory considerations. Given that titanium is primarily extracted from titanium-bearing ores, any fluctuations in the supply chain can significantly affect pricing. Additionally, regulatory measures aimed at reducing environmental impact can result in increased operational costs, influencing the overall pricing of rutile TiO2.

Factors Influencing Competitive Pricing

1. Raw Material Costs The primary source of titanium dioxide is the mineral ilmenite, which is processed to obtain titanium. Variations in raw material costs due to mining regulations, transportation costs, or geopolitical factors can directly impact the price suppliers charge.

2. Production Techniques Different production methods (sulfate vs. chloride processes) lead to variations in cost structure. The chloride process, whilst more environmentally friendly, is typically more capital-intense, influencing supplier pricing strategies.

3. Supply and Demand Dynamics Global demand for rutile TiO2 is robust, driven by growth in end-use industries like construction and automotive. As demand continues to rise, suppliers are urged to remain competitive in pricing to retain market share.

4. Technological Innovations Suppliers investing in advanced technologies can produce TiO2 more efficiently and sustainably, reducing costs in the long run. Those who do not invest in innovation may find it challenging to compete on price.

competitive price rutile titanium dioxide suppliers

5. Quality and Performance Competitive pricing is not only about being the lowest in the market. Suppliers that can demonstrate superior quality or performance characteristics will often justify higher prices. This can be particularly important in specialized applications where performance is critical.

6. Sustainability Practices There is a growing trend toward environmentally sustainable practices in the chemical industry. Suppliers that adopt sustainable practices may attract customers who are willing to pay a premium for responsibly sourced materials.

Strategies for Suppliers

Suppliers looking to offer competitive prices for rutile TiO2 can consider several strategies

- Optimize Production Investing in process improvements that increase efficiency can lower production costs. Utilizing waste materials or byproducts can also significantly reduce expenses. - Diversify Supply Sources Establishing relationships with multiple raw material suppliers can mitigate the risk of price volatility and ensure a more stable supply chain.

- Focus on Niche Markets Instead of competing directly on price with large producers, suppliers can focus on niche markets that require specialized products or high-quality materials where competition is less fierce.

- Enhance Customer Relationships Maintaining strong relationships with customers can provide insight into their needs and can foster loyalty, enabling suppliers to adopt more resilient pricing structures.

Conclusion

The rutile titanium dioxide market is dynamic and competitive, with pricing influenced by various factors from raw material costs to production technologies. As suppliers navigate this landscape, it is essential to find a balance between competitive pricing and maintaining product quality. By adopting innovative production methods, focusing on customer relationships, and embracing sustainability, suppliers can position themselves effectively in the market and ensure long-term success.

-

China Lithopone in China Supplier – High Quality Lithopone ZnS 30% Powder for Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Company – Premium TiO2 Powder Supplier & Manufacturer

NewsJun.10,2025

-

Fast Shipping 99% Pure TiO2 Powder CAS 13463-67-7 Bulk Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Manufacturers High-Purity R996 & Anatase

NewsJun.10,2025

-

Lithopone MSDS Factories - Production & Quotes

NewsJun.10,2025

-

High-Quality Titanium Dioxide in Water Suppliers - China Expertise 60

NewsJun.09,2025