វិច្ឆិកា . 05, 2024 13:55 Back to list

antase and rutile type titanium dioxide factories

Titanium dioxide (TiO2) is a critical material used in a wide variety of applications, from paints and coatings to plastics and food products. Among the different forms of titanium dioxide, anatase and rutile are the two primary crystal structures, each possessing unique properties that cater to specific industrial needs. Understanding these two types and the manufacturing processes of TiO2 can provide insightful perspectives on their significance in various sectors.

Anatase and rutile differ primarily in their crystal structure, which influences their physical and chemical properties. Anatase is a tetragonal crystal structure that is typically more reactive than rutile. This heightened reactivity makes anatase a preferred choice in photocatalytic applications, such as self-cleaning surfaces and environmental remediation, where it can break down organic pollutants under UV light. In contrast, rutile, with its more stable tetragonal form, exhibits less reactivity; however, it is renowned for its exceptional performance as a pigment due to its superior opacity and brightness. This makes rutile the material of choice for applications requiring high durability and color-fastness, such as in paints, coatings, and plastics.

The manufacturing processes for anatase and rutile titanium dioxide are vital to their end-use performance and functionality

. Generally, these processes can be categorized into two main techniques sulfate and chloride processes.The sulfate process, which has been traditionally used for the production of titanium dioxide, begins with the reaction of titanium ores, such as ilmenite, with sulfuric acid to produce titanium sulfate. This intermediate product is subsequently hydrolyzed and calcined to yield anatase or rutile TiO2, depending on the conditions. However, the sulfate process can generate a significant amount of waste, which poses environmental challenges that have drawn scrutiny in recent years.

antase and rutile type titanium dioxide factories

On the other hand, the chloride process is a more contemporary method that is gaining traction due to its lower environmental impact. In this method, titanium ores are reacted with chlorine at high temperatures to produce titanium tetrachloride (TiCl4). This precursor is then subjected to oxidation, resulting in the formation of TiO2. The chloride process is particularly preferred for the production of rutile titanium dioxide, as it allows for a more efficient extraction of the desired crystal structure with fewer impurities, resulting in a higher-quality product.

In terms of market demand, the choice between anatase and rutile often hinges on the specific requirements of the application. The global market for titanium dioxide continues to grow, driven by the expanding use of TiO2 in construction, automotive, and consumer products. As industries strive for sustainability, the development of more environmentally friendly production methods and the recycling of TiO2 pigments has also become a focal point for manufacturers.

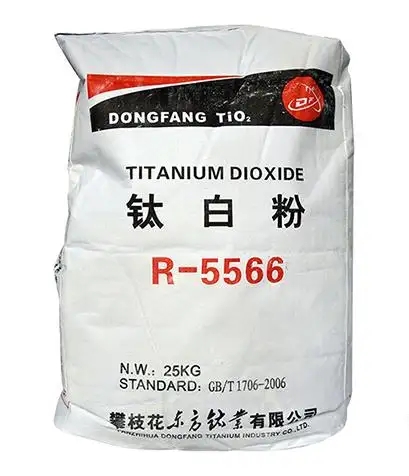

Many factories around the world specialize in the production of anatase and rutile titanium dioxide, each utilizing its unique processes. China is currently a leading producer, leveraging vast titanium ore resources and advancing production technologies. Several companies are investing in research and development to optimize production efficiency, reduce waste, and enhance the performance characteristics of their TiO2 products.

In summary, the diversity between anatase and rutile titanium dioxide extends beyond their crystal structures; it influences manufacturing processes and, ultimately, the scope of their applications. With ongoing advancements in production technologies and increasing environmental considerations, the future of titanium dioxide manufacturing is poised for transformation. Industries relying on this essential pigment will benefit from innovations that allow for more sustainable practices while ensuring that the unique properties of anatase and rutile continue to meet market demands.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025