វិច្ឆិកា . 14, 2024 08:44 Back to list

13463-67-7 titanium dioxide factories

Titanium Dioxide Factories An Overview of Production and Applications

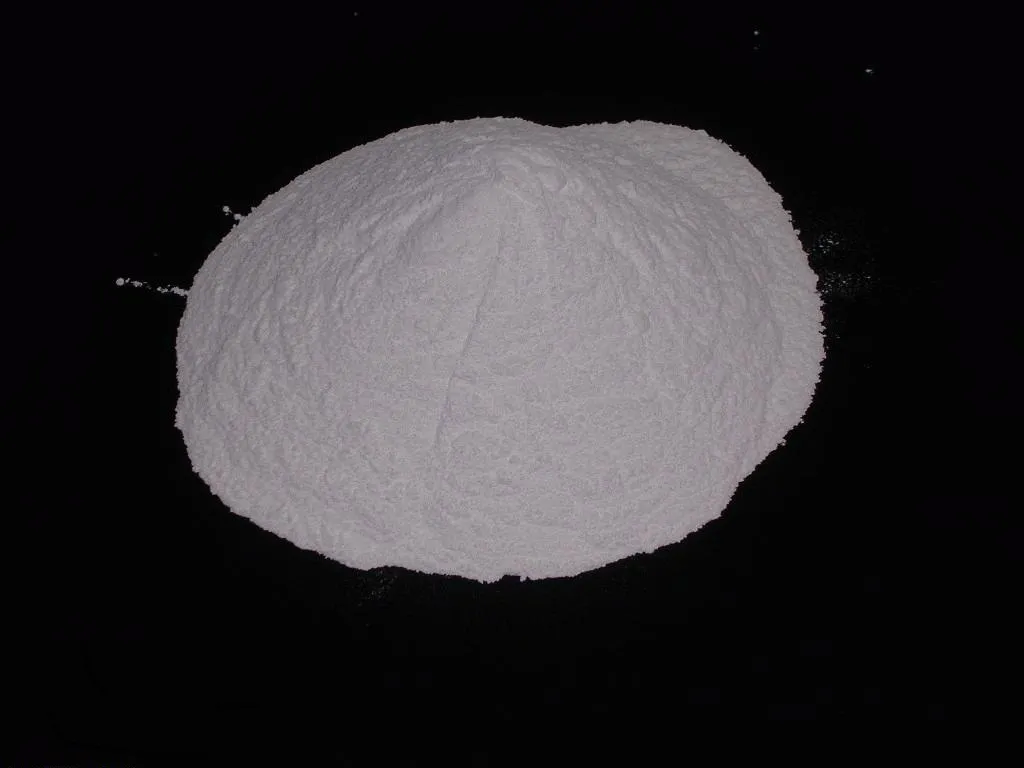

Titanium dioxide (TiO2), identified by the chemical index 13463-67-7, is one of the most widely used compounds in the world today. This white, opaque powder is known for its high refractive index and strong ultraviolet light absorbing capabilities, making it invaluable in various industries, including paints, coatings, plastics, cosmetics, and food. The manufacturing of titanium dioxide is a complex process that involves several stages, from mining raw materials to producing the final product in factories.

Raw Material Sourcing

The primary raw materials used in the production of titanium dioxide are titanium-bearing minerals such as ilmenite, rutile, and leucoxene. These minerals are typically extracted from open-pit mines or from beach sands. The mining process can have significant environmental impacts, which have led to strict regulations and monitoring. Sustainable practices, including land reclamation and careful water management, are increasingly being adopted by titanium dioxide manufacturers to mitigate these effects.

Production Processes

There are two main processes used to produce titanium dioxide the sulfate process and the chloride process.

1. Sulfate Process This traditional method begins with the digestion of ilmenite in sulfuric acid. The reaction produces titanium sulfate, which is further hydrolyzed to produce titanium dioxide. The sulfate process is less expensive but generates a significant amount of waste, leading to environmental concerns.

2. Chloride Process This is a more modern and environmentally friendly method that uses chlorine gas to convert titanium-bearing ores into titanium tetrachloride (TiCl4). The TiCl4 is then oxidized to produce high-purity titanium dioxide. The chloride process is known for its higher efficiency and lower environmental impact compared to the sulfate process, making it the preferred choice for many manufacturers today.

Global Production Landscape

13463-67-7 titanium dioxide factories

The production of titanium dioxide is concentrated in a few key regions around the world. Major titanium dioxide manufacturers include companies such as DuPont, Chemours, Huntsman, and Tronox. These factories are strategically located in areas with access to raw materials and transportation infrastructure. Asia, particularly China, has seen rapid growth in titanium dioxide production, driven by increasing domestic demand for paints, coatings, and plastics.

Applications of Titanium Dioxide

Titanium dioxide's primary application is in the pigment industry, where it is used for its whiteness and brightness. It is a critical ingredient in paints and coatings, providing excellent coverage and durability. Additionally, TiO2 is used in plastics to enhance color and opacity, making it fundamental in the production of everything from packaging materials to automotive components.

In the cosmetics industry, titanium dioxide serves as a key ingredient in sunscreen formulations due to its ability to block ultraviolet radiation. Its safety and efficacy have made it a standard in the production of lotions and creams. Furthermore, TiO2 is also used in the food industry as a coloring agent, though its use has become subject to scrutiny in some regions due to health concerns.

Environmental and Health Concerns

Despite its benefits, the production of titanium dioxide is associated with several environmental and health concerns. The manufacturing processes can release harmful pollutants and waste products, necessitating strict regulatory compliance. Moreover, there have been discussions regarding the safety of titanium dioxide in inhalable forms, particularly in relation to its use in consumer products. Ongoing research is essential to assess these risks and ensure the safe application of titanium dioxide across its various industries.

Conclusion

Titanium dioxide production is a critical industry that supports numerous sectors globally. As demand continues to rise, especially in emerging markets, the industry faces the challenge of balancing production efficiency with environmental sustainability. With advancements in manufacturing processes and increased regulatory scrutiny, titanium dioxide factories are evolving to meet the demands of a changing world while striving to minimize their impact on the environment and public health.

-

AI-Enhanced Titania Tio2 | High-Performance Solutions

NewsAug.04,2025

-

Titanium Dioxide TiO2 Enhanced by GPT-4 Turbo for Industry

NewsAug.03,2025

-

Advanced Titania TIO2 Solutions with GPT-4 Turbo AI Tech

NewsAug.02,2025

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025