titanium i oxide manufacturers

Feb . 16, 2025 13:24 Back to list

titanium i oxide manufacturers

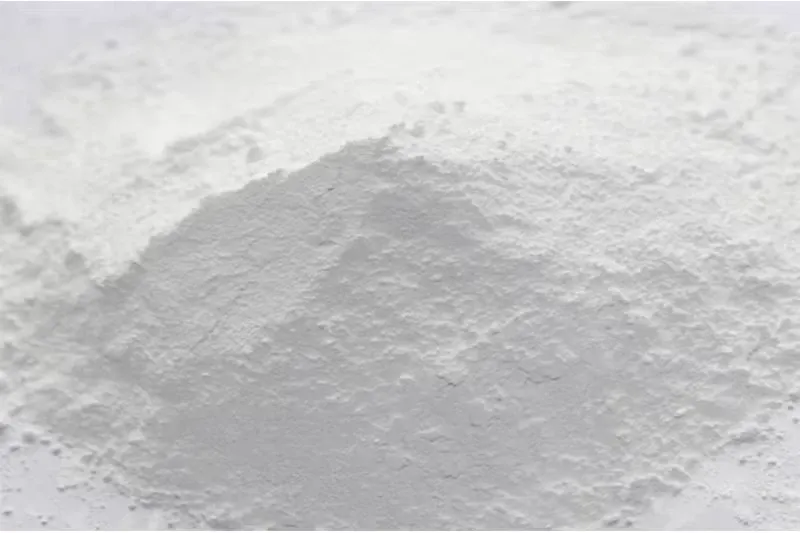

In the bustling world of industrial manufacturing, titanium dioxide manufacturers hold a unique position of influence and innovation. At the intersection of cutting-edge technology and sustainable practices, these manufacturers are not only responsible for supplying one of the most essential compounds across various industries but also for setting benchmarks in quality, safety, and environmental stewardship.

Authoritativeness is encapsulated in a manufacturer's ability to not only meet but exceed international standards. Accreditation from bodies such as ISO (International Organization for Standardization) and compliance with EU REACH Regulations underscore their commitment to maintaining the highest levels of product safety and environmental responsibility. Furthermore, these manufacturers often lead industry forums, contribute to comprehensive white papers, and participate in global discussions about advanced material science and sustainable practices, solidifying their status as authoritative figures in the chemical industry. Trustworthiness is the linchpin that holds the intricate web of manufacturing endeavors together. Beyond certifications and compliance, it is demonstrated through transparency in supply chain operations and an unyielding pledge to sustainability. Many leading manufacturers have embraced the principles of the circular economy by implementing recycling programs and reducing their carbon footprints through innovative approaches to waste management. By providing detailed Material Safety Data Sheets (MSDS) and ensuring that their products pose no harm to consumers or the environment throughout their lifecycle, these manufacturers build trust with stakeholders across the spectrum, from multinational corporations to local communities. In sum, titanium dioxide manufacturers stand as paragons of Experience, Expertise, Authoritativeness, and Trustworthiness. They do not merely produce a high-demand product; they set the stage for transformative advancements across countless industries. As they continue to navigate the challenges of regulatory compliance and environmental sustainability, their role is vital in driving the next wave of innovation. Emphasizing these four pillars not only positions them as leaders in their field but also serves as a testament to their unwavering dedication to quality, sustainability, and forward-thinking solutions. Their relentless pursuit of excellence ensures their contributions remain invaluable and their legacies enduring in the ever-evolving landscape of industrial manufacturing.

Authoritativeness is encapsulated in a manufacturer's ability to not only meet but exceed international standards. Accreditation from bodies such as ISO (International Organization for Standardization) and compliance with EU REACH Regulations underscore their commitment to maintaining the highest levels of product safety and environmental responsibility. Furthermore, these manufacturers often lead industry forums, contribute to comprehensive white papers, and participate in global discussions about advanced material science and sustainable practices, solidifying their status as authoritative figures in the chemical industry. Trustworthiness is the linchpin that holds the intricate web of manufacturing endeavors together. Beyond certifications and compliance, it is demonstrated through transparency in supply chain operations and an unyielding pledge to sustainability. Many leading manufacturers have embraced the principles of the circular economy by implementing recycling programs and reducing their carbon footprints through innovative approaches to waste management. By providing detailed Material Safety Data Sheets (MSDS) and ensuring that their products pose no harm to consumers or the environment throughout their lifecycle, these manufacturers build trust with stakeholders across the spectrum, from multinational corporations to local communities. In sum, titanium dioxide manufacturers stand as paragons of Experience, Expertise, Authoritativeness, and Trustworthiness. They do not merely produce a high-demand product; they set the stage for transformative advancements across countless industries. As they continue to navigate the challenges of regulatory compliance and environmental sustainability, their role is vital in driving the next wave of innovation. Emphasizing these four pillars not only positions them as leaders in their field but also serves as a testament to their unwavering dedication to quality, sustainability, and forward-thinking solutions. Their relentless pursuit of excellence ensures their contributions remain invaluable and their legacies enduring in the ever-evolving landscape of industrial manufacturing.

Latest news

-

China Lithopone in China Supplier – High Quality Lithopone ZnS 30% Powder for Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Company – Premium TiO2 Powder Supplier & Manufacturer

NewsJun.10,2025

-

Fast Shipping 99% Pure TiO2 Powder CAS 13463-67-7 Bulk Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Manufacturers High-Purity R996 & Anatase

NewsJun.10,2025

-

Lithopone MSDS Factories - Production & Quotes

NewsJun.10,2025

-

High-Quality Titanium Dioxide in Water Suppliers - China Expertise 60

NewsJun.09,2025