titanium dioxide anatase factory

Gen . 28, 2025 01:43 Back to list

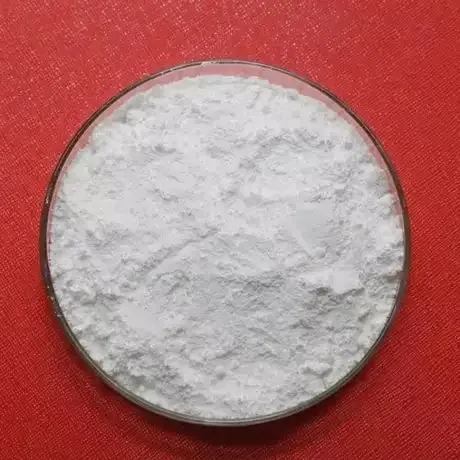

titanium dioxide anatase factory

Navigating the intricacies of the titanium dioxide anatase manufacturing sector unveils a world where expertise and innovation converge to create some of the most essential compounds in various industries. Titanium dioxide, particularly in its anatase form, is prized for its superior photocatalytic properties, making it a cornerstone material for applications ranging from environmental catalysts to photovoltaic devices.

Authoritative knowledge extends beyond production expertise into compliance with environmental and safety standards. Factories are subject to rigorous inspections and must operate in accordance with international regulations that govern chemical manufacturing and emissions. Implementing sustainable practices is not just a regulatory compliance measure but a commitment to reducing the environmental impact inherent in titanium dioxide production. Trustworthiness in this industry also hinges on transparent product quality assurances. An effective titanium dioxide anatase production unit prioritizes comprehensive quality control. This involves routine sampling and evaluation of the product's physical and chemical properties to meet strict international quality standards. End users, ranging from manufacturers of paints and coatings to producers of sunscreens and cosmetics, rely on consistent product quality to ensure the performance and safety of their own products. Furthermore, a titanium dioxide anatase factory embraces continuous innovation. Research and development teams are dedicated to enhancing production techniques and developing new applications for anatase titanium dioxide. From advancing photocatalytic applications in air and water purification systems to improving energy efficiency in low-temperature catalysis, innovation is the lifeblood that sustains and propels this industry forward. Building trust with clients and partners also involves robust logistical and customer support frameworks. Reliable supply chain management, timely delivery, and personalized technical support ensure factory products can integrate seamlessly into customers’ existing processes, maximizing their benefit and reaffirming their utility. In essence, the world of titanium dioxide anatase factories represents a confluence of science, technology, and sustainable practice. By prioritizing quality, compliance, and innovation, these factories not only supply a versatile material used in myriad applications but also set benchmarks for industry-wide best practices. For those seeking unmatched performance and reliability, titanium dioxide anatase remains an indispensable choice, underpinned by a legacy of expertise and commitment to excellence.

Authoritative knowledge extends beyond production expertise into compliance with environmental and safety standards. Factories are subject to rigorous inspections and must operate in accordance with international regulations that govern chemical manufacturing and emissions. Implementing sustainable practices is not just a regulatory compliance measure but a commitment to reducing the environmental impact inherent in titanium dioxide production. Trustworthiness in this industry also hinges on transparent product quality assurances. An effective titanium dioxide anatase production unit prioritizes comprehensive quality control. This involves routine sampling and evaluation of the product's physical and chemical properties to meet strict international quality standards. End users, ranging from manufacturers of paints and coatings to producers of sunscreens and cosmetics, rely on consistent product quality to ensure the performance and safety of their own products. Furthermore, a titanium dioxide anatase factory embraces continuous innovation. Research and development teams are dedicated to enhancing production techniques and developing new applications for anatase titanium dioxide. From advancing photocatalytic applications in air and water purification systems to improving energy efficiency in low-temperature catalysis, innovation is the lifeblood that sustains and propels this industry forward. Building trust with clients and partners also involves robust logistical and customer support frameworks. Reliable supply chain management, timely delivery, and personalized technical support ensure factory products can integrate seamlessly into customers’ existing processes, maximizing their benefit and reaffirming their utility. In essence, the world of titanium dioxide anatase factories represents a confluence of science, technology, and sustainable practice. By prioritizing quality, compliance, and innovation, these factories not only supply a versatile material used in myriad applications but also set benchmarks for industry-wide best practices. For those seeking unmatched performance and reliability, titanium dioxide anatase remains an indispensable choice, underpinned by a legacy of expertise and commitment to excellence.

Next:

Latest news

-

China Lithopone in China Supplier – High Quality Lithopone ZnS 30% Powder for Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Company – Premium TiO2 Powder Supplier & Manufacturer

NewsJun.10,2025

-

Fast Shipping 99% Pure TiO2 Powder CAS 13463-67-7 Bulk Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Manufacturers High-Purity R996 & Anatase

NewsJun.10,2025

-

Lithopone MSDS Factories - Production & Quotes

NewsJun.10,2025

-

High-Quality Titanium Dioxide in Water Suppliers - China Expertise 60

NewsJun.09,2025