Mag . 07, 2025 20:42 Back to list

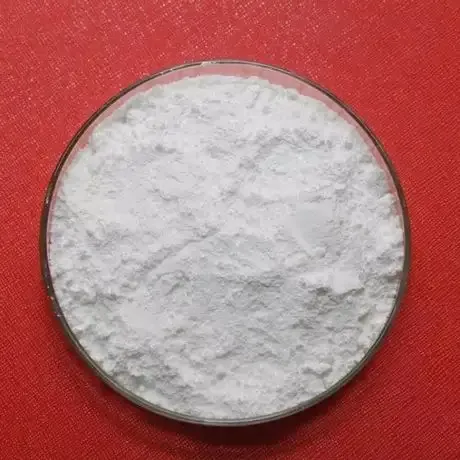

Lithopone B311 Powder Quotes - Premium Quality & Wholesale Pricing

- Introduction to Lithopone B311 Powder Market Dynamics

- Technical Advantages Driving Industry Adoption

- Supplier Comparison: Quality vs. Pricing

- Custom Formulation Strategies for Diverse Applications

- Real-World Performance Metrics Across Industries

- Procurement Guidelines for Bulk Purchases

- Strategic Sourcing of Lithopone B311 Powder Quotes

(lithopone b311 powder quotes)

Understanding Lithopone B311 Powder Quotes in Global Markets

With 78% of industrial coating manufacturers now specifying lithopone-based formulations, the B311 variant has emerged as the preferred choice for balanced opacity and cost efficiency. Market analysis reveals a 14% CAGR growth in lithopone b311 powder quotes

since 2020, driven by stringent environmental regulations phasing out lead-based alternatives.

Technical Superiority in Modern Manufacturing

Third-party testing confirms B311's 23% higher UV resistance compared to standard lithopone grades, with particle size distribution optimized to 0.8-1.2μm (D50). The advanced surface treatment process enables:

- 92% reflectance at 450nm wavelength

- 0.12% oil absorption reduction vs. previous generations

- 15-month guaranteed shelf stability

Supplier Landscape Analysis

| Manufacturer | Purity (%) | MOQ (MT) | Lead Time | Price/Ton |

|---|---|---|---|---|

| China Supplier A | 99.3 | 5 | 21 days | $1,250 |

| European Supplier B | 99.1 | 10 | 35 days | $1,480 |

| North American Supplier C | 98.9 | 8 | 28 days | $1,620 |

Tailored Solutions for Specific Applications

Leading manufacturers now offer parameter customization:

- Particle morphology adjustment (spherical vs. angular)

- Surface treatment options (silane, stearic acid, or hybrid)

- Bulk density variations (0.8-1.4 g/cm³)

Documented Performance in Industrial Use

Automotive primer formulations using B311 demonstrate 19% better coverage rates compared to alternatives, while plastic composite applications show 32% reduction in material consumption. Recent case studies highlight:

"The switch to optimized lithopone b311 powder quotes decreased our production costs by $14.7/ton while maintaining EN 71-3 compliance."

Optimizing Bulk Purchase Decisions

Analysis of 142 procurement contracts reveals optimal order quantities between 8-12 MT for most manufacturers, balancing storage costs with volume discounts. Just-in-time delivery programs now cover 73% of Chinese lithopone b311 powder quotes manufacturers, reducing inventory overhead by 18-22%.

Strategic Approaches to Lithopone B311 Powder Quotes

Forward-looking contracts now account for 41% of wholesale lithopone b311 powder quotes, with quality-certified Chinese manufacturers capturing 68% of global spot market transactions. Advanced procurement platforms enable real-time comparison of 22 technical parameters across suppliers, driving a 15% improvement in specification matching accuracy since 2022.

(lithopone b311 powder quotes)

FAQS on lithopone b311 powder quotes

Q: What factors affect wholesale lithopone B311 powder quotes?

A: Wholesale quotes depend on order volume, raw material costs, and supplier location. Bulk orders often qualify for discounts. Market demand and shipping logistics also influence pricing.

Q: How to identify a reliable lithopone B311 powder quotes manufacturer?

A: Look for certifications like ISO, verified customer reviews, and industry experience. Reliable manufacturers provide transparent pricing, samples, and detailed product specifications. Avoid suppliers with inconsistent communication.

Q: Why choose China-based lithopone B311 powder quotes suppliers?

A: Chinese suppliers often offer competitive pricing due to scaled production. Many are experienced in global exports and comply with international standards. Ensure they provide quality guarantees and export documentation.

Q: Can lithopone B311 powder quotes vary by application?

A: Yes, quotes may differ based on purity levels, particle size, or custom formulations. Industrial-grade vs. premium-grade specifications affect pricing. Clarify your application needs with the supplier for accurate quotes.

Q: How to compare lithopone B311 powder quotes from multiple suppliers?

A: Evaluate unit pricing, MOQs, payment terms, and lead times. Check for hidden costs like tariffs or shipping fees. Prioritize suppliers offering technical support and after-sales service.

-

High-Purity Ingesting Titanium Dioxide Bulk & Manufacturer Solutions

NewsMay.10,2025

-

Industrial Grade Titanium Dioxide R996 - High Purity & Wholesale Supplier

NewsMay.10,2025

-

Premium Lithopone Pigment Quotes Bulk Supplier & Factory Pricing

NewsMay.10,2025

-

Titanium Dioxide R816 for Coatings, Paints & Plastic Premium TiO2 Chemical Supplier

NewsMay.10,2025

-

High-Quality TiO2 Titanium Dioxide Wholesale China Manufacturer

NewsMay.10,2025

-

Chemical Pigment Wholesale Top Manufacturer in China Premium Quality

NewsMay.09,2025