Des . 10, 2024 07:58 Back to list

first class lithopone factory

The Rise of First-Class Lithopone Factories

Lithopone, a versatile white pigment, has gained significant recognition in various industries due to its excellent opacity and durability. The rise of first-class lithopone factories marks an important milestone in the production of this essential compound, and it is crucial to understand the factors contributing to their emergence, the production process, and the broad applications of lithopone.

Understanding Lithopone

Lithopone is a mixture of zinc sulfide and barium sulfate, primarily used as a pigment in paints, coatings, plastics, and other materials. Its ability to provide a brilliant white color and its high resistance to discoloration makes it ideal for use in a wide array of product formulations. The quest for non-toxic, high-performance pigments has further spurred interest in lithopone, especially as industries strive to meet stringent environmental regulations.

The Emergence of First-Class Factories

The establishment of first-class lithopone factories is driven by several key factors. One of the primary reasons is the growing demand for high-quality pigments in the paint and coatings industry. As manufacturers become increasingly aware of environmental impacts and consumer preferences shift towards eco-friendly products, the need for higher-grade lithopone has surged.

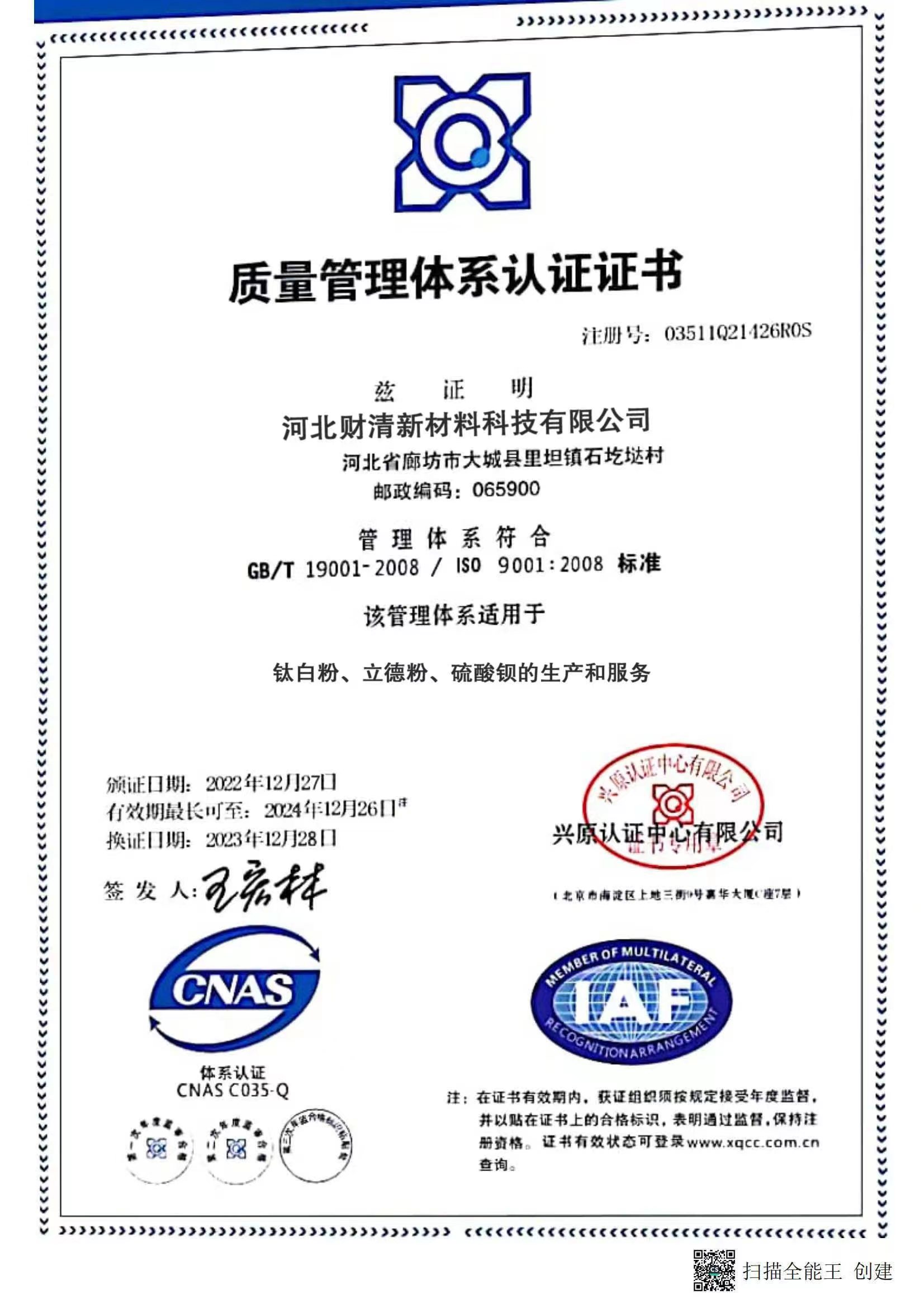

Investment in modern technology is another highlight of first-class lithopone factories. Sophisticated manufacturing processes, such as advanced milling techniques and precise blending operations, have increased both the efficiency and quality of lithopone production. By employing cutting-edge equipment and quality control systems, these facilities can produce lithopone that meets or exceeds international standards.

Furthermore, the globalization of trade has enabled first-class factories to access raw materials and market their products worldwide

. With the ability to source high-purity zinc and barium compounds, these manufacturers ensure that their lithopone is not only cost-effective but also of superior quality.Manufacturing Process of Lithopone

first class lithopone factory

The production of lithopone generally involves several stages raw material preparation, synthesis, separation, and drying. The primary components, zinc sulfide and barium sulfate, are processed in a controlled environment to ensure optimal purity and performance.

In the initial phase, high-quality raw materials are carefully selected and mixed in specific ratios. This mixture is then subjected to a series of chemical reactions that lead to the formation of lithopone. Separation processes help in isolating the resultant pigment, which is then dried to attain the desired powder consistency.

Quality control is paramount in first-class lithopone factories. Rigorous testing methods are employed at various stages of production to ensure that the final product adheres to established specifications. This commitment to quality guarantees that clients receive a pigment that performs well across different applications.

Applications of Lithopone

The versatility of lithopone allows it to be used in a myriad of applications. In the paint and coatings industry, it provides excellent coverage and brightness, making it a favorite choice among manufacturers. It also finds its way into plastics, rubber products, and even cosmetics, where its non-toxic nature and stability are highly valued.

In addition, lithopone is utilized in the production of ceramics, where it imparts a smooth finish and enhances color vibrancy. The construction industry also benefits from its use in building materials, where it contributes to both aesthetic and functional properties.

Conclusion

The advent of first-class lithopone factories signifies a promising advancement in pigment production, driven by technological innovation and a commitment to quality. As industries continue to seek sustainable and high-performance solutions, the role of lithopone as a key pigment will likely expand. The investment in superior production facilities not only elevates the standards of lithopone but also supports a growing market keen on environmentally friendly options, ensuring that this remarkable compound remains a staple in various applications for years to come.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025