Des . 11, 2024 11:16 Back to list

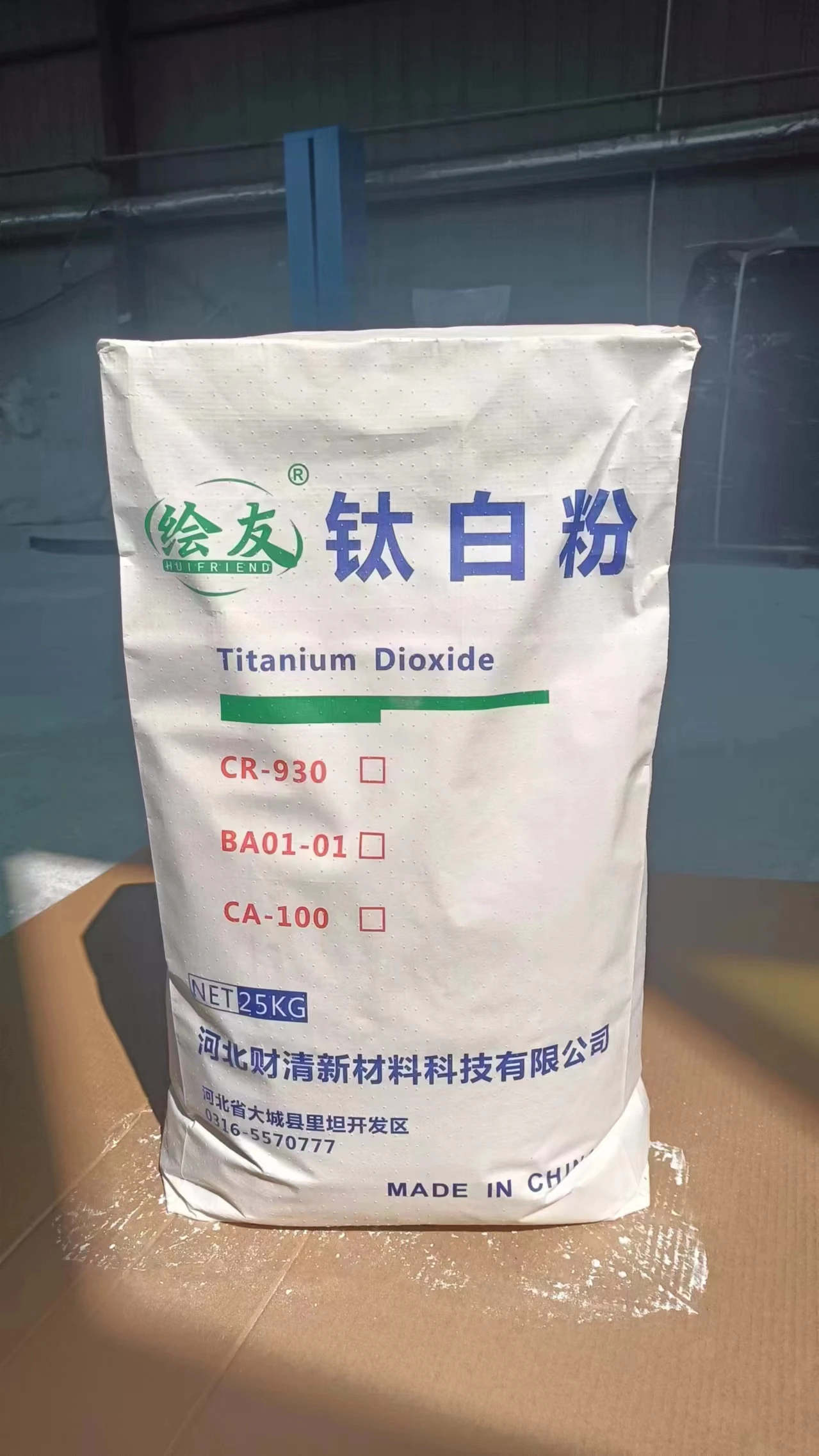

factory tio2 powder rutile titanium dioxide factory

Exploring the Factory Production of Rutile Titanium Dioxide Powder

Rutile titanium dioxide (TiO2) is a critical material widely utilized in various industries due to its exceptional properties such as high refractive index, excellent UV resistance, and superior opacity. The growing demand for titanium dioxide powder, particularly rutile grade, has led to a surge in the establishment of specialized factories dedicated to its production. This article explores the processes, applications, and significance of factories producing rutile titanium dioxide powder.

Understanding Rutile Titanium Dioxide

Rutile is one of the three different crystal modifications of titanium dioxide, with the other two being anatase and brookite. Rutile titanium dioxide is particularly notable for its high stability and durability, making it the preferred choice for applications demanding long-lasting performance. One of the most distinguished characteristics of rutile TiO2 is its ability to effectively scatter light, providing brilliant whiteness, which makes it a key ingredient in the production of paints, coatings, plastics, and paper products.

Manufacturing Process of Rutile TiO2 Powder

The manufacturing of rutile titanium dioxide powder involves several intricate processes

. The most widely adopted method is the sulfate route and the chloride route.1. Sulfate Process This method begins with the digestion of ilmenite ore in sulfuric acid. The reaction produces titanyl sulfate, which is then hydrolyzed to form titanium dioxide. After the formation, it undergoes calcination at high temperatures to convert the anatase form into the more stable rutile phase. The resultant rutile is then milled to produce fine powder before being packaged for distribution.

2. Chloride Process In contrast, the chloride process starts with the chlorination of titanium ore, such as ilmenite or rutile itself, using carbon in the presence of chlorine gas. The chlorination produces titanium tetrachloride (TiCl4), which is then oxidized to form TiO2. The chloride route typically yields purer and more consistent grades of TiO2 powder, making it a popular choice among manufacturers.

factory tio2 powder rutile titanium dioxide factory

Both methods require advanced technologies to ensure efficiency, quality, and environmental compliance. Factories producing rutile titanium dioxide must be equipped with sophisticated machinery and adhere to stringent regulations regarding emissions and waste management to mitigate the environmental impact.

Applications Across Industries

Rutile titanium dioxide powder finds extensive application across various sectors. In the paint and coatings industry, it is prized for its opacity and brightness, ensuring that products achieve vibrant colors and long-lasting finishes. Similarly, in the plastics industry, TiO2 enhances UV resistance, allowing products to maintain their appearance and structural integrity over time.

Furthermore, rutile titanium dioxide is utilized in the production of paper, contributing to the brightness and printability of the finished products. Additionally, its photocatalytic properties have led to its use in the development of self-cleaning surfaces and air purification systems.

Economic Importance and Sustainability

The production of rutile titanium dioxide powder represents not only technological advancement but also significant economic potential. Factories involved in its manufacturing play a vital role in local economies, providing employment opportunities and stimulating related industries. Moreover, with the increased focus on sustainability, manufacturers are now adopting greener practices and innovations to reduce their carbon footprint and enhance the recyclability of their products.

Conclusion

The factory production of rutile titanium dioxide powder is a testament to the advancements in chemical manufacturing and the industrial applications of this versatile material. The methods used in its production, coupled with its extensive applications in diverse industries, highlight the importance of TiO2 as a pivotal component in modern manufacturing. As industries continue to evolve towards greater efficiency and sustainability, the role of titanium dioxide, particularly in its rutile form, will undoubtedly expand, underpinning its significance in our daily lives and the global economy.

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025

-

High Quality Titanium Dioxide Used in Rubber – Trusted Supplier & Factory Price

NewsJul.08,2025

-

High Purity Barium Sulfate Particle Size - Wholesale Manufacturer from China

NewsJul.07,2025

-

Premium Titanium Dioxide Lomon R-996 Supplier – Quality & Wholesale Price from China

NewsJul.07,2025

-

Top Titanium Manufacturers in China - Quality Titanium Dioxide Supplier & Production Line Solutions

NewsJul.06,2025

-

OEM Titanium White Supplier & Factory – High Purity, Consistent Quality for Industrial Use

NewsJul.06,2025