Des . 10, 2024 21:02 Back to list

Estimation of Sulphate Content in Titanium Dioxide Production Processes and Methods

Estimation of Sulphate in Titanium Dioxide Production

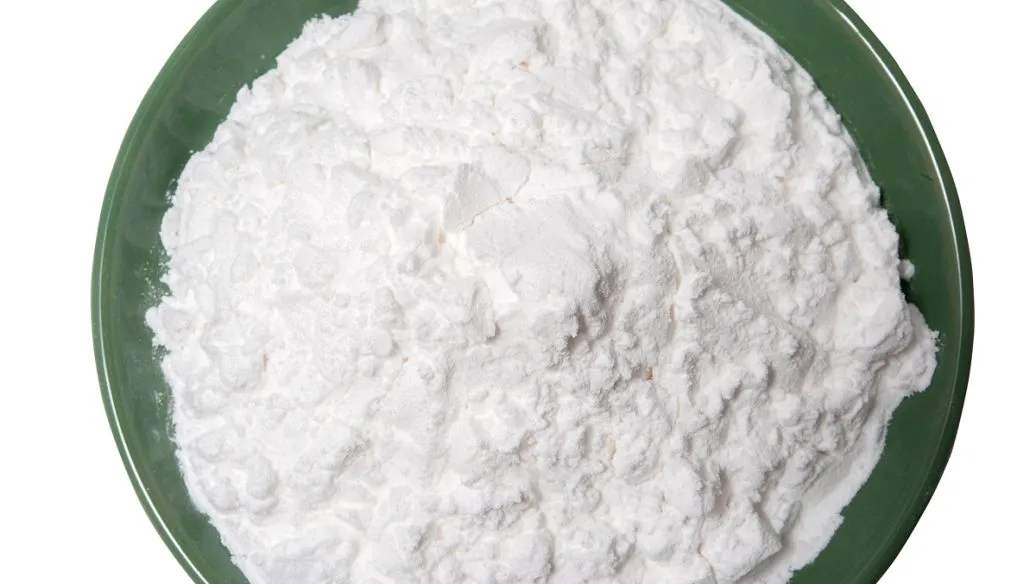

The production of titanium dioxide (TiO2) is a vital industry that plays a critical role in various applications, including pigments, coatings, plastics, and food products. One of the key raw materials involved in this production process is sulphate. The estimation of sulphate as it relates to the manufacturing of titanium dioxide is essential for ensuring both product quality and environmental compliance.

Overview of Titanium Dioxide Production

Titanium dioxide is primarily produced using two methods the sulfate process and the chloride process. The sulfate process involves the reaction of titanium-containing minerals, such as ilmenite, with sulfuric acid. This method generates by-products, including iron and other metal sulfates, and is known for its cost-effectiveness and ability to handle lower-grade ores. In contrast, the chloride process employs titanium tetrachloride, which is derived from high-purity rutile, leading to fewer impurities but at a higher production cost.

In the sulfate process, after the ilmenite is reacted with sulfuric acid, the resultant mixture is subjected to hydrolysis, yielding titanium sulfate. This titanium sulfate can then be further processed to obtain titanium dioxide. Thus, understanding the sulphate content during various stages of production is critical, both for optimizing the process and meeting regulatory standards.

Importance of Sulphate Estimation

Estimating sulphate levels during the titanium dioxide manufacturing process is crucial for several reasons. First, controlling the sulphate concentration is essential for managing the quality of the final product. Excessive sulphates can lead to undesirable properties in TiO2, such as reduced opacity and altered hue, which are critical for product performance in coatings and pigments.

Second, the estimation of sulphate is vital to minimize environmental impact. The sulfate process produces significant amounts of waste, and without proper management, it can lead to environmental pollution. Accurate sulphate estimation aids in the design of efficient waste treatment processes, ensuring compliance with environmental legislation. Many regions have stringent regulations governing the discharge of sulphate into water bodies, due to its potential to cause eutrophication.

estimation of sulphate as titanium dioxide factory

Methods of Estimating Sulphate

Multiple analytical methods can be employed for the estimation of sulphate in titanium dioxide production. Common techniques include gravimetric analysis, ion chromatography, and spectrophotometric methods.

1. Gravimetric Analysis This classic method involves precipitating sulphate as barium sulfate (BaSO4) and then weighing the precipitate. While highly accurate, it is time-consuming and requires careful handling.

2. Ion Chromatography This modern technique allows for the rapid quantification of anions, including sulphate. It provides high sensitivity and can analyze multiple ions simultaneously, which is beneficial in complex samples.

3. Spectrophotometry Sulphate can also be estimated via colourimetric methods, where it is converted to a colored complex, and the intensity of the color is measured. This method is simple and quick, but it may suffer from interferences if other anions are present.

Conclusion

Understanding and estimating sulphate during the titanium dioxide production process play a pivotal role in ensuring product quality, optimizing production efficiency, and adhering to environmental regulations. As the demand for titanium dioxide continues to rise globally, manufacturers must leverage advanced analytical techniques to monitor sulfate levels effectively. By doing so, they can enhance operational efficiencies, minimize environmental impacts, and ensure that their products meet the required standards of excellence. As industries increasingly focus on sustainability, the role of effective sulphate estimation will become even more critical in the titanium dioxide sector.

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025

-

High Quality Titanium Dioxide Used in Rubber – Trusted Supplier & Factory Price

NewsJul.08,2025

-

High Purity Barium Sulfate Particle Size - Wholesale Manufacturer from China

NewsJul.07,2025

-

Premium Titanium Dioxide Lomon R-996 Supplier – Quality & Wholesale Price from China

NewsJul.07,2025

-

Top Titanium Manufacturers in China - Quality Titanium Dioxide Supplier & Production Line Solutions

NewsJul.06,2025

-

OEM Titanium White Supplier & Factory – High Purity, Consistent Quality for Industrial Use

NewsJul.06,2025