Titanium Dioxide Pigment for Paints and Coatings

Feb . 16, 2025 03:13 Back to list

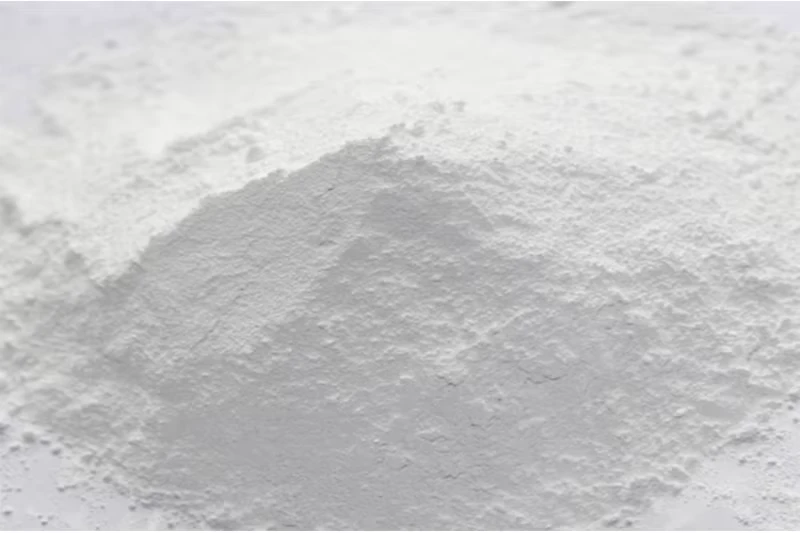

Titanium Dioxide Pigment for Paints and Coatings

Aeroxide TiO2, more commonly known as titanium dioxide, is a vital compound used in a myriad of industries. From cosmetics to electronics, and even in environmental applications, it plays a critical role in enhancing product performance. Understanding the intricacies of Aeroxide TiO2 factories requires a deep dive into their operations, safety measures, technological advancements, and environmental impacts.

Beyond production, these factories also focus on reducing their environmental footprint. Titanium dioxide production can be energy-intensive, so leading manufacturers have invested heavily in innovative technologies designed to minimize energy consumption and waste. From using renewable energy sources to implementing closed-loop systems that reduce emissions, Aeroxide TiO2 factories continuously explore new ways to align with environmental sustainability goals. The authoritativeness of information from Aeroxide TiO2 factories is reinforced by their commitment to transparency and community engagement. Many factories actively participate in research collaborations with academic institutions and industry bodies to advance knowledge and innovation in titanium dioxide applications. This collaboration not only boosts their expertise but also ensures that they remain at the forefront of industry developments, subsequently enhancing their product offerings. In terms of trustworthiness, these factories demonstrate a dedicated adherence to global regulatory requirements. By complying with regulations set by bodies such as the Environmental Protection Agency (EPA) and the European Chemicals Agency (ECHA), they provide assurance to clients and consumers regarding the safety and reliability of their products. Additionally, many companies are now documenting and publishing their sustainability initiatives and performance metrics, which further reinforces public trust. In conclusion, Aeroxide TiO2 factories epitomize a blend of high-level expertise, cutting-edge technology, and an unwavering commitment to safety and sustainability. As the demand for titanium dioxide continues to grow, these factories are not only focusing on scaling up production but are also pioneering advancements that align with global environmental and safety standards. The fusion of experience, expertise, and trustworthiness ensures that they continue to be key players in the production of high-quality titanium dioxide, catering to a diverse range of industrial applications. Through continued innovation and adherence to regulatory practices, Aeroxide TiO2 factories are well-positioned to meet the evolving needs of global industries.

Beyond production, these factories also focus on reducing their environmental footprint. Titanium dioxide production can be energy-intensive, so leading manufacturers have invested heavily in innovative technologies designed to minimize energy consumption and waste. From using renewable energy sources to implementing closed-loop systems that reduce emissions, Aeroxide TiO2 factories continuously explore new ways to align with environmental sustainability goals. The authoritativeness of information from Aeroxide TiO2 factories is reinforced by their commitment to transparency and community engagement. Many factories actively participate in research collaborations with academic institutions and industry bodies to advance knowledge and innovation in titanium dioxide applications. This collaboration not only boosts their expertise but also ensures that they remain at the forefront of industry developments, subsequently enhancing their product offerings. In terms of trustworthiness, these factories demonstrate a dedicated adherence to global regulatory requirements. By complying with regulations set by bodies such as the Environmental Protection Agency (EPA) and the European Chemicals Agency (ECHA), they provide assurance to clients and consumers regarding the safety and reliability of their products. Additionally, many companies are now documenting and publishing their sustainability initiatives and performance metrics, which further reinforces public trust. In conclusion, Aeroxide TiO2 factories epitomize a blend of high-level expertise, cutting-edge technology, and an unwavering commitment to safety and sustainability. As the demand for titanium dioxide continues to grow, these factories are not only focusing on scaling up production but are also pioneering advancements that align with global environmental and safety standards. The fusion of experience, expertise, and trustworthiness ensures that they continue to be key players in the production of high-quality titanium dioxide, catering to a diverse range of industrial applications. Through continued innovation and adherence to regulatory practices, Aeroxide TiO2 factories are well-positioned to meet the evolving needs of global industries.

Latest news

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025