Nov . 05, 2025 00:40 Back to list

tio2 Pigment: High Purity, R902 & P25, UV Shielding

Tio2 is a key solution in the chemical industry industry, specifically within fine chemicals and Manufacturing of inorganic pigments. This article explores how Hebei Caiqing New Material Technology Co., LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Tio2 Overview

- Benefits & Use Cases of Tio2 in Manufacturing of inorganic pigments

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in chemical industry

- Conclusion on Tio2 from Hebei Caiqing New Material Technology Co., LTD

Tio2 Overview

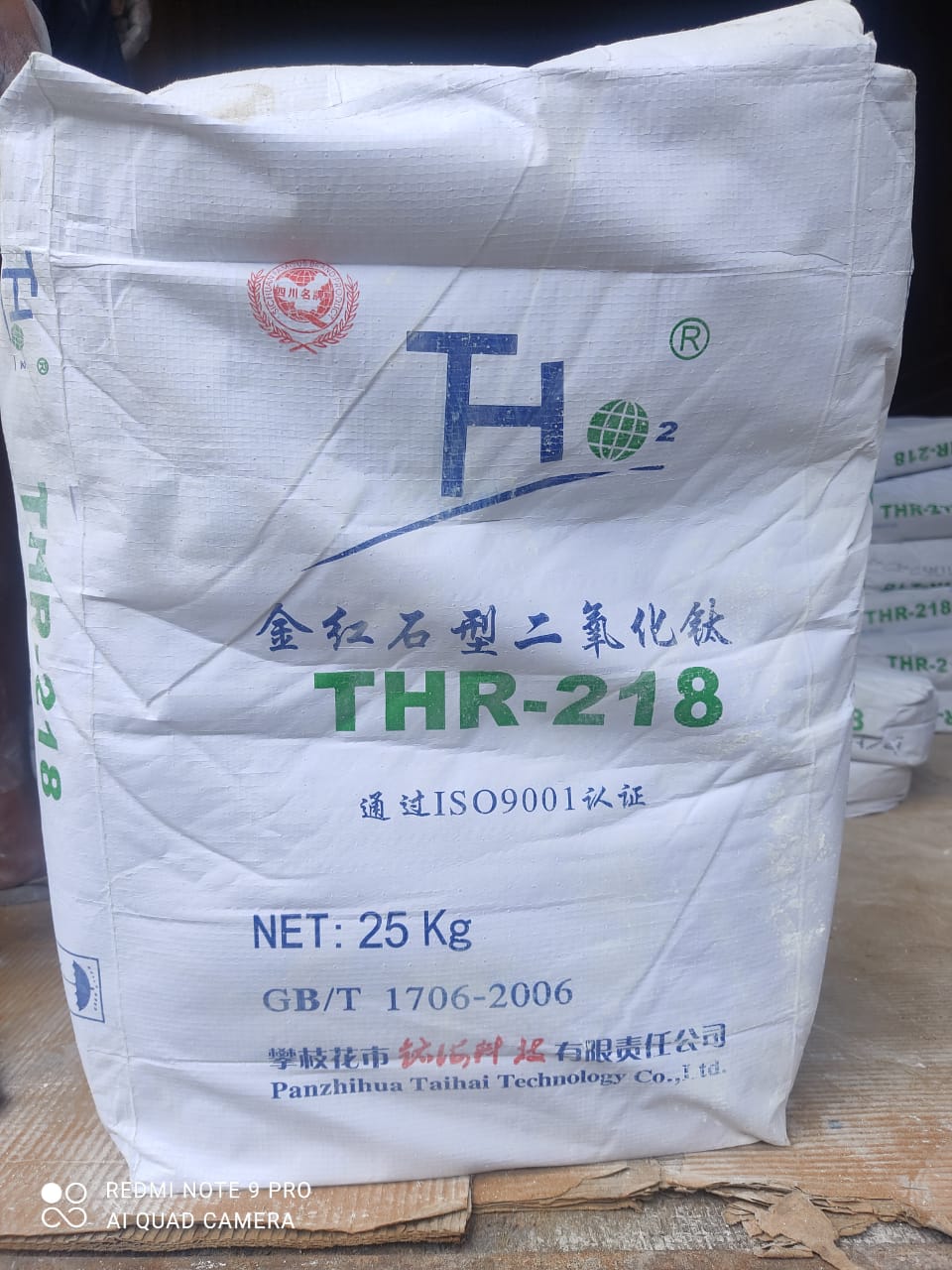

Titanium dioxide (TiO2) is the workhorse white pigment for coatings, inks, plastics, and masterbatches. With an exceptionally high refractive index and optimized particle size distribution, TiO2 delivers opacity, brightness, and UV durability that alternative fillers cannot match. For B2B buyers in fine chemicals and the Manufacturing of inorganic pigments, TiO2 is the performance backbone behind color consistency, gloss, and hiding power targets. Hebei Caiqing New Material Technology Co., LTD supplies production-proven grades like THR‑218 for painting, coating, and ink formulations, engineered for fast dispersion and stable tint strength in both solventborne and waterborne systems.

In procurement conversations, you may encounter different naming conventions and grades such as R902 TiO2 (often compared with r902 tio2 or tio2 r902), P25 TiO2 for photocatalysis (p25 tio2 / tio2 p25), and references to ISK TiO2 equivalents (isk tio2). Some sourcing lists even use shorthand like “.c TiO2.” Regardless of label, what matters is the surface treatment, particle morphology, and dispersion behavior—factors that drive real-world outcomes. Hebei Caiqing’s solutions balance ti in TiO2 crystal stability, surface chemistry, and processing to reduce grind time, improve film integrity, and help customers meet tight quality specifications at scale.

Benefits & Use Cases of Tio2 in Manufacturing of inorganic pigments

In coatings and inks, TiO2 usage is centered on maximizing hiding at the lowest possible PVC and grind energy. Typical applications include architectural paints (interior/exterior), industrial primers and topcoats, automotive refinishes, powder coatings, and high-solids inks. For ink makers, a well-engineered TiO2 paste can simplify dispersion and ensure press-ready whiteness, while in plastics, TiO2 supports UV screening and color retention. Compared with commodity alternatives, premium rutile TiO2 types provide superior weatherability, chalk resistance, and whiteness retention—critical in exterior coatings and high-durability finishes.

Hebei Caiqing New Material Technology Co., LTD focuses on consistent particle size, robust surface treatment, and cleanliness to enhance gloss, tint strength, and film smoothness. Customers often benchmark against well-known grades like R902 TiO2; our portfolio is engineered to meet modern coating line requirements, helping reduce rework and improve batch-to-batch uniformity. Whether your spec calls for universal rutile for multi-resin compatibility or a specialized grade, our technical team helps match the right TiO2 types to your system—waterborne, solventborne, UV/EB, or powder—so performance and cost objectives align from lab to plant.

Cost, Maintenance & User Experience

Total cost of ownership for TiO2 is driven by more than the invoice line. TiO2 cost should be evaluated alongside letdown ratios, dispersion time, energy consumption, film performance, and warranty claims. A highly dispersible rutile pigment with stable viscosity can cut grind cycles, reduce wear on media mills, and shorten cleaning intervals—tangible savings that improve ROI. In many systems, optimizing loading by 1–2% while retaining opacity can offset price moves and lower formulation complexity. If your process favors ready-to-use intermediates, a controlled TiO2 paste can further streamline production and inventory handling.

Feedback from coatings and ink producers indicates improved whiteness consistency, fewer filter blockages, and predictable rheology when switching to tighter-spec pigments. Users also note easier color matching versus legacy materials labeled “tio2 is equivalent” but lacking surface treatment robustness. Hebei Caiqing backs supply with technical service, documentation, and batch traceability to support scale-up and quality audits, helping procurement teams balance cost, risk, and performance across changing demand cycles.

Sustainability & Market Trends in chemical industry

Across the TiO2 value chain, sustainability pressures and regulations are shaping purchasing strategies. Buyers increasingly request transparency on energy intensity, waste management, and heavy metal limits, along with documentation to support compliance in major markets. Trends include optimizing chloride/sulfate route operations, developing lower-VOC systems that disperse efficiently, and extending coating lifetimes to reduce repaint cycles. Specialty segments are also growing—such as P25 TiO2 for photocatalytic and antimicrobial surfaces—while mainstream demand continues to prefer durable rutile TiO2 types for long-term weathering performance.

Hebei Caiqing New Material Technology Co., LTD positions customers for the future with quality-focused manufacturing, process control, and an emphasis on resource efficiency. We collaborate on formulation choices that maintain performance while supporting sustainability goals, from optimizing PVC to selecting surface treatments that reduce energy-intensive dispersion. As regulations evolve, our team provides timely documentation and guidance so your materials strategy remains resilient—technically, commercially, and environmentally.

Conclusion on Tio2 from Hebei Caiqing New Material Technology Co., LTD

From architectural paints to high-spec industrial inks, TiO2 is the critical pigment that enables opacity, brightness, and durability. Selecting the right grade impacts everything from throughput and formulation cost to long-term film performance. Hebei Caiqing New Material Technology Co., LTD delivers dependable quality, technical support, and supply stability to help B2B teams hit their performance and budget targets. Contact us: email: sales01@cqtitaniumdioxide.com. Visit our website: https://www.cqtitaniumdioxide.com

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025