अगस्त . 14, 2024 18:20 Back to list

The Role of Titanium Dioxide in Enhancing Plastic Production and Its Applications

The Role of Titanium Dioxide in Plastic Manufacturing

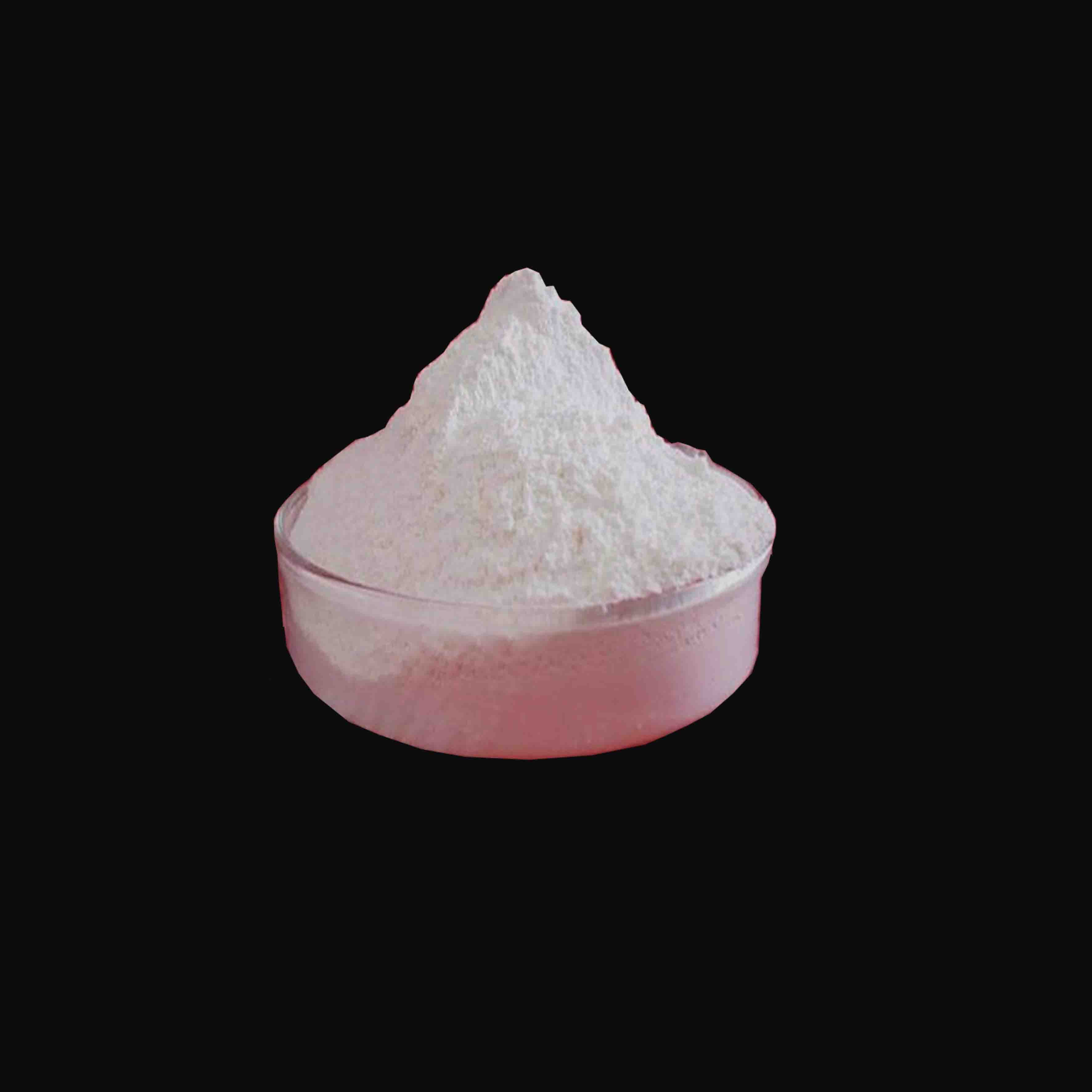

Titanium dioxide (TiO2) has become an indispensable component in the plastic manufacturing industry, mainly due to its unique properties and versatile applications. As one of the most widely used white pigments, titanium dioxide offers not only exceptional opacity and brightness but also remarkable durability and resistance to UV radiation. This article explores the importance of titanium dioxide in plastics, its benefits, and the ongoing developments that shape its utilization in manufacturing.

Properties and Applications

Titanium dioxide is celebrated for its high refractive index, which allows it to scatter light effectively. This characteristic is critical in producing plastics that require excellent whiteness and brightness, making it a popular additive in various products such as containers, automotive parts, and construction materials. When incorporated into plastics, titanium dioxide enhances the aesthetic appeal of the final product, giving it a luminous white finish that is hard to replicate with other compounds.

Moreover, titanium dioxide exhibits outstanding chemical resistance. When plastics are exposed to environmental elements, including UV light, humidity, and temperature fluctuations, TiO2 helps maintain the integrity of the material. This makes it particularly beneficial for outdoor applications, as it aids in preventing yellowing and degradation, thereby prolonging the lifespan of the product.

Environmental Considerations and Safety

In recent years, the emphasis on sustainability and environmental safety has prompted extensive research into the use of titanium dioxide in plastics. The aerospace, automotive, and consumer goods sectors are increasingly demanding eco-friendly solutions. Titanium dioxide is non-toxic, making it a preferable choice compared to other pigments that might pose health risks.

titanium dioxide used in plastic manufacturer

Furthermore, developments in the production of titanium dioxide, particularly in the methods of extraction and processing, are moving towards more sustainable practices. Manufacturers are prioritizing the use of high-quality, natural sources of TiO2 and reducing waste in the production process, contributing to a smaller ecological footprint for plastic products.

Innovations and Future Directions

As the plastic manufacturing industry continues to evolve, so does the role of titanium dioxide. Researchers are exploring nano-sized titanium dioxide particles, which offer enhanced properties and performance. These nanostructured particles can improve the mechanical strength and thermal stability of plastics while providing greater efficiency in the utilization of TiO2. This innovation holds the promise of not only improving the quality of plastic products but also reducing the overall quantity of pigment needed, leading to cost savings and a reduction in the environmental impact.

Additionally, the growing trend towards bioplastics and recyclable materials is paving the way for new ways to incorporate titanium dioxide. The compatibility of TiO2 with bio-based polymers presents exciting opportunities for developing sustainable plastic solutions that maintain performance standards while being environmentally friendly.

Conclusion

Titanium dioxide's significance in plastic manufacturing cannot be overstated. It brings forth a host of benefits, including aesthetic enhancement, UV stability, and chemical resistance, all of which are crucial for the durability and quality of plastic products. As industries strive for sustainability, the focus on the safe and efficient use of titanium dioxide will continue to be a focal point in research and development. With innovations driving its applications into new realms, titanium dioxide will likely remain a key player in the future of plastic manufacturing, contributing toward a balanced intersection of performance, safety, and environmental responsibility.

-

Best Baso4 Price Wholesale & Manufacturer Deals in China

NewsApr.29,2025

-

Rutile Titanium Dioxide R698 Supplier Coating & Paint Solutions

NewsApr.29,2025

-

Premium Titanium Dioxide Ultra White Paint High-Coverage & Durable

NewsApr.29,2025

-

China Titanium & TiO2 Powder Factory Reliable Rutile & Lithopone Supplier

NewsApr.28,2025

-

Titanium Dioxide Types High-Purity Grades from Trusted Factories & Suppliers

NewsApr.28,2025

-

High-Quality Titanium Dioxide White Pigments Wholesale Supplier

NewsApr.28,2025