दिसम्बर . 23, 2024 22:46 Back to list

rutile titanium dioxide mbr9668-coating manufacturers

The Significance of Rutile Titanium Dioxide in Coating Applications

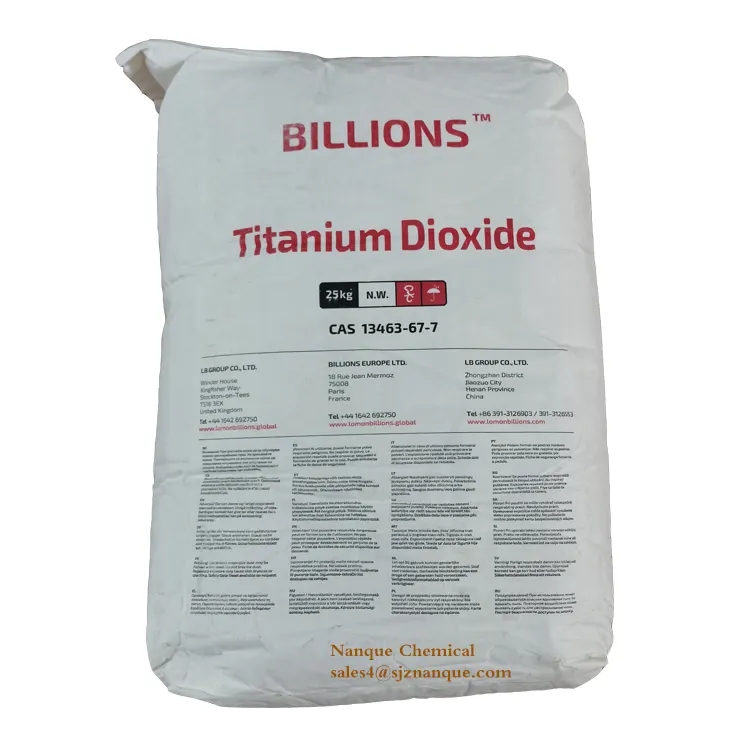

Rutile titanium dioxide (TiO2) is a widely-used pigment renowned for its exceptional whiteness, brightness, and UV resistance. It is primarily utilized in various coating applications, ranging from architectural paints to industrial coatings and plastics. Its unique properties make it an essential component in many manufacturing processes, leading to its high demand globally. Among manufacturers, the focus on rutile TiO2, specifically formulations like MBR9668, has gained traction in recent years, prompting a closer look at its benefits and applications.

Understanding Rutile Titanium Dioxide

Rutile titanium dioxide comes in two primary crystalline forms rutile and anatase. The rutile form is predominately used in industrial applications due to its superior opacity and UV resistance, making it ideal for use in coatings. It is derived from titanium ore through various extraction processes and has established itself as a staple in various manufacturing industries, particularly in coatings.

Advantages of Rutile TiO2 in Coatings

1. Excellent Opacity and Whiteness Rutile titanium dioxide is prized for its high refractive index, which provides excellent hiding power. This allows manufacturers to use less pigment while achieving desired opacity, reducing overall material costs. The bright white color of rutile also enhances the aesthetic appeal of coatings.

2. Durability Coatings formulated with rutile TiO2 are known for their durability and long-lasting performance. They have excellent weather resistance and scratch resistance, making them suitable for exterior applications where exposure to sunlight, moisture, and adverse weather conditions is prevalent.

3. UV Stability Rutile TiO2 is effective in absorbing harmful UV rays, protecting underlying surfaces from degradation. This characteristic is particularly crucial in outdoor applications, where exposure to UV radiation can lead to color fading and material breakdown over time.

4. Chemical Resistance Coatings containing rutile titanium dioxide exhibit enhanced resistance to various chemicals, making them ideal for industrial settings. This quality ensures that the coatings maintain their integrity when exposed to solvents, acids, and other harsh substances.

rutile titanium dioxide mbr9668-coating manufacturers

5. Versatility Rutile TiO2 can be easily incorporated into a variety of formulations, including water-based and solvent-based coatings. This versatility allows manufacturers to tailor products to specific applications and customer requirements.

MBR9668 A Leading Formulation

Among the diverse range of titanium dioxide products, MBR9668 has emerged as a notable coating formulation. As a high-grade rutile titanium dioxide, it is specifically designed to meet the rigorous demands of modern coating technologies. MBR9668 offers enhanced properties such as superior dispersibility, allowing it to integrate seamlessly into coating systems. This results in improved application characteristics and final product performance.

Environmental Considerations

In recent years, there has been a growing emphasis on the environmental impact of manufacturing processes. Rutile titanium dioxide manufacturers are increasingly adopting eco-friendly practices, such as minimizing waste and emissions during production. Additionally, the inherent properties of TiO2 contribute to sustainability, as coatings formulated with this pigment can reduce energy consumption by reflecting sunlight and lowering heat absorption.

The Future of Rutile TiO2 in Coatings

The future of rutile titanium dioxide in coating applications looks promising, with ongoing innovations in formulations and application techniques. As industries seek to produce more sustainable and high-performance products, the role of rutile TiO2 will continue to evolve. Manufacturers are investing in research and development to create new formulations that enhance functionality while addressing environmental concerns.

In conclusion, rutile titanium dioxide, particularly formulations like MBR9668, plays a critical role in the coatings industry. Its exceptional properties, coupled with its versatility and durability, make it an indispensable component in various applications. With a continued focus on sustainability and performance, rutile TiO2's significance in the manufacturing sector is poised to grow. Manufacturers must remain aware of the latest trends and innovations to leverage the benefits of rutile titanium dioxide fully, ensuring their products meet the demands of an ever-evolving market.

-

China Lithopone in China Supplier – High Quality Lithopone ZnS 30% Powder for Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Company – Premium TiO2 Powder Supplier & Manufacturer

NewsJun.10,2025

-

Fast Shipping 99% Pure TiO2 Powder CAS 13463-67-7 Bulk Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Manufacturers High-Purity R996 & Anatase

NewsJun.10,2025

-

Lithopone MSDS Factories - Production & Quotes

NewsJun.10,2025

-

High-Quality Titanium Dioxide in Water Suppliers - China Expertise 60

NewsJun.09,2025