दिसम्बर . 11, 2024 02:37 Back to list

Estimation of Sulphate Levels in Titanium Dioxide Production Processes for Manufacturers

Estimation of Sulphate as Titanium Dioxide An Overview of Manufacturers

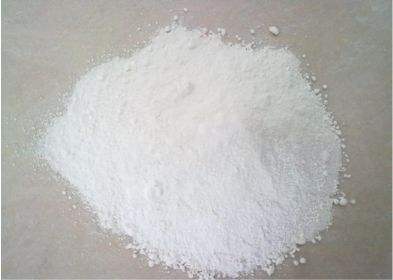

Titanium dioxide (TiO2) is a widely utilized white pigment, renowned for its high opacity, brightness, and UV resistance. It is predominantly used in industries such as paints, coatings, plastics, and cosmetics. The production of titanium dioxide can be achieved through various methods, with the sulfate process and the chloride process being the most prominent. This article delves into the estimation of sulphate-based titanium dioxide and reviews some leading manufacturers in the field.

Understanding the Sulfate Process

The sulfate process for producing titanium dioxide begins with the extraction of ilmenite ore (FeTiO3). This ore undergoes a series of chemical reactions involving sulfuric acid, which ultimately leads to the formation of titanium sulfate. The resultant titanium sulfate solution is then subjected to hydrolysis, which precipitates titanium dioxide. After filtering and washing, the product is calcined to improve its properties, resulting in high-purity titanium dioxide.

One of the main advantages of the sulfate process is its relatively low cost compared to the chloride process, which utilizes titanium tetrachloride as its intermediate. However, the sulfate process generates considerable quantities of waste, including iron sulfate, necessitating effective waste management strategies.

Estimation of Sulphate Content in Titanium Dioxide

In evaluating the quality of titanium dioxide produced via the sulfate process, the estimation of sulphate content is crucial. Sulphate impurities can affect the performance characteristics of titanium dioxide, including opacity, color, and dispersion. Manufacturers are therefore tasked with implementing analytical techniques to quantify sulphate levels during production.

Common methods for estimating sulfate in titanium dioxide include gravimetric methods, ion chromatography, and spectrophotometry. These techniques help manufacturers ensure that the end product meets regulatory standards and specific customer requirements.

Key Manufacturers in the Titanium Dioxide Industry

Several manufacturers have established a strong foothold in the titanium dioxide market, utilizing the sulfate process or combining it with the chloride process

. Here are a few notable playersestimation of sulphate as titanium dioxide manufacturers

1. Chemours Company Chemours is one of the largest producers of titanium dioxide globally, operating both sulfate and chloride production facilities. The company emphasizes sustainable practices and innovative solutions, providing a range of titanium dioxide products that cater to various applications.

2. Tronox Holdings plc Tronox is a leading producer of titanium dioxide, largely focusing on the sulfate process. With operations spanning multiple countries, they are known for their high-quality TiO2 products that meet stringent quality control measures, including sulfate content estimation.

3. Huntsman Corporation Huntsman produces titanium dioxide through different processes and is committed to research and development in the field. The company frequently invests in modernizing its facilities to minimize waste generation and enhance product performance.

4. Lomon Billions Based in China, Lomon Billions is one of the top titanium dioxide manufacturers in Asia. They employ both the sulfate and chloride processes and have developed proprietary methods to optimize sulphate estimation during production, ensuring their products maintain high quality.

5. Valspar (part of Sherwin-Williams) Known for their coatings and paints, Valspar incorporates titanium dioxide into their products, sourcing from reputable manufacturers. They prioritize high-performance TiO2 with low sulphate content to ensure optimal aesthetic and functional properties in coatings.

Challenges and Future Outlook

The titanium dioxide industry faces several challenges, including environmental regulations concerning waste management and emissions. As governments around the world impose stricter regulations, manufacturers are under pressure to develop more sustainable production methods, especially concerning the sulphate process.

Future trends may see increased investments in technology that enhances sulphate reduction and improves recycling of by-products. Innovations in analytical techniques for estimating sulphate will also play a pivotal role in ensuring product quality and compliance.

In conclusion, the estimation of sulphate content in titanium dioxide production is a critical aspect that manufacturers must address to ensure quality and compliance. As industry leaders adopt more sustainable practices, the focus on refining the sulfate process and enhancing product quality will contribute to the growth and evolution of the titanium dioxide market.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025