नवम्बर . 16, 2024 06:14 Back to list

classification of titanium dioxide manufacturers

Classification of Titanium Dioxide Manufacturers

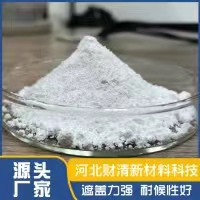

Titanium dioxide (TiO2) is a highly versatile compound widely used across various industries, including paints, coatings, plastics, paper, and cosmetics. Its excellent whiteness and brightness, coupled with its ability to absorb UV light, make it an essential ingredient in products requiring durability and opacity. Due to its significant industrial applications, the titanium dioxide market has seen a proliferation of manufacturers worldwide. In this article, we will explore the classification of titanium dioxide manufacturers based on different criteria such as production process, scale of operation, and geographical location.

1. By Production Process

Titanium dioxide manufacturers can primarily be classified into two categories based on their production methods the sulfate process and the chloride process.

- Sulfate Process Manufacturers This traditional method involves the reaction of titanium ore (usually ilmenite) with sulfuric acid to produce titanium dioxide. While this process can produce lower-grade products, it is often more economical for manufacturers using lower-quality titanium ores. Companies employing the sulfate process typically produce TiO2 that serves in applications where durability and high performance are less critical.

- Chloride Process Manufacturers This advanced method uses chlorine gas to convert titanium ores into titanium tetrachloride (TiCl4), which is then oxidized to produce high-purity titanium dioxide. The chloride process is known for producing superior quality TiO2 with finer particle sizes and enhanced properties. Manufacturers utilizing this process often cater to high-end markets, including premium paints, coatings, plastics, and even food-grade applications.

2. By Scale of Operation

Manufacturers can be further classified based on their scale of operation, which includes large-scale industrial producers, medium-sized firms, and small enterprises.

- Large-scale Manufacturers These companies tend to dominate the market, equipped with extensive facilities and advanced technologies to produce titanium dioxide at scale. They benefit from economies of scale, allowing them to offer competitive prices while maintaining high product quality. Major players in the industry such as Chemours, Tronox, and Huntsman are recognized for their substantial market shares and global reach.

classification of titanium dioxide manufacturers

- Medium-sized Firms These manufacturers often specialize in niche markets and may focus on specific applications of titanium dioxide. They balance quality and cost-effectiveness, providing customized solutions to their clients. While they may not have the massive production capabilities of large corporations, they often excel in flexibility, innovation, and personalized customer service.

- Small Enterprises Smaller manufacturers can be found in specialized markets where customization and specific performances of titanium dioxide are essential. They might produce tailored products for unique applications or local markets, forging strong relationships with their customers. While they face challenges competing against larger corporations, they can thrive by focusing on quality and specialized product offerings.

3. By Geographical Location

The geographical classification of titanium dioxide manufacturers reveals regional trends in production and demand.

- North America Home to some of the largest players in the industry, North America has a well-established market characterized by high-quality production facilities. Companies here often engage in significant research and development, driving innovations in product formulations.

- Asia-Pacific This region has emerged as a major hub for titanium dioxide production due to the availability of raw materials and lower labor costs. Countries like China and Japan are leading producers, not only supplying domestic demand but also exporting TiO2 to global markets.

- Europe European manufacturers focus heavily on high-quality standards and sustainable production methods, often complying with stringent environmental regulations. They typically produce for industries that prioritize performance, such as cosmetics and high-end coatings.

Conclusion

The classification of titanium dioxide manufacturers is multifaceted, reflecting variations in production processes, operational scales, and geographical distribution. Understanding these classifications helps businesses navigate the complex market landscape, enabling them to choose the right suppliers that meet their specific needs. As industries continue to evolve and demand for titanium dioxide grows, manufacturers will need to adapt and innovate to remain competitive in this dynamic market.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025