Sep . 23, 2025 09:20 Back to list

13463-67-7 Titanium Dioxide Coating Supplier | High Quality TiO2

Strategic Sourcing of CAS 13463-67-7 Titanium Dioxide for Advanced Coating Applications

In the highly specialized realm of industrial coatings, the selection of raw materials directly impacts product performance, durability, and cost-efficiency. Titanium dioxide (TiO₂) with CAS number 13463-67-7 stands as the preeminent white pigment, critical for achieving opacity, brightness, and UV resistance in a vast array of coating formulations. For B2B stakeholders, identifying a reliable 13463-67-7 titanium dioxide using for coating supplier is not merely a procurement task; it is a strategic decision influencing market competitiveness and product integrity. This comprehensive guide delves into the technical aspects, industry dynamics, and strategic considerations for sourcing high-quality TiO₂ for coating applications.

The demand for superior coating performance—encompassing enhanced weatherability, scratch resistance, and aesthetic appeal—drives continuous innovation in material science. As a critical component, CAS 13463-67-7 titanium dioxide, available from reputable 13463-67-7 titanium dioxide using for coating manufacturer, offers unparalleled pigmentary properties, making it indispensable across diverse sectors from automotive and construction to packaging and marine. Understanding the nuances of its production, technical specifications, and application benefits is paramount for informed decision-making.

Industry Trends and Market Dynamics for Coating-Grade TiO₂

The global titanium dioxide market, particularly for coating applications, is experiencing steady growth, projected to reach over USD 25 billion by 2027, with a CAGR of approximately 6% (Source: Grand View Research). Key drivers include rapid urbanization, increasing infrastructure development, and a rising demand for high-performance coatings in the automotive and aerospace industries. Environmental regulations are also influencing product innovation, pushing for lower VOC (Volatile Organic Compound) content in coatings, where high-performance TiO₂ can maintain opacity at reduced film thicknesses. The market is segmented into Rutile and Anatase grades, with Rutile dominating due to its superior durability and weathering resistance.

Emerging trends include advancements in surface treatment technologies for TiO₂, leading to enhanced dispersibility, UV stability, and photocatalytic activity control. The shift towards sustainable manufacturing practices also impacts the supply chain, requiring dye pigment cas 13463-67-7 titanium dioxide factory operations to adhere to stricter environmental standards. Furthermore, the push for more specialized coatings, such as anti-corrosion, self-cleaning, and heat-reflective paints, necessitates tailor-made TiO₂ solutions.

Technical Specifications and Product Grades

Titanium dioxide, CAS 13463-67-7, primarily exists in two crystalline forms relevant to coatings: Rutile and Anatase. Each offers distinct properties suitable for specific applications.

- Rutile Titanium Dioxide: Characterized by higher refractive index, superior opacity, and excellent UV light absorption. It provides better weatherability, chalk resistance, and tinting strength, making it ideal for durable exterior coatings, automotive paints, and industrial finishes. Products like wholesale hot sale titanium dioxide rutile lomon r996 exemplify high-performance rutile grades.

- Anatase Titanium Dioxide: While possessing a slightly lower refractive index and less UV absorption than rutile, anatase offers higher brightness and a bluish undertone. It is often preferred in interior coatings, paper, and certain plastics where chalking is less critical, or where specific optical properties are desired. Wholesale titanium dioxide b101 anatase powder is a common choice for these applications.

Typical Product Specification Table (Rutile Grade for Coatings)

| Parameter | Specification (Rutile R-996 Equivalent) | Test Method |

|---|---|---|

| TiO₂ Content (%) | ≥ 93.0 | ISO 591-1:2018 |

| Rutile Content (%) | ≥ 98.0 | XRD Analysis |

| Volatile Matter (105°C, %) | ≤ 0.5 | ISO 787-2:1981 |

| Residue on Sieve (45µm, %) | ≤ 0.05 | ISO 787-18:1983 |

| Oil Absorption (g/100g) | 18-22 | ISO 787-5:1995 |

| pH Value | 6.5 - 8.0 | ISO 787-9:1981 |

| Specific Gravity (g/cm³) | 4.0 - 4.2 | ASTM D153 |

Manufacturing Process Flow of Coating-Grade Titanium Dioxide (CAS 13463-67-7)

The production of high-quality `13463-67-7 titanium dioxide using for coating` involves sophisticated chemical engineering processes, primarily the Sulfate process and the Chloride process. Both methods convert raw titanium-bearing ores into finely controlled pigmentary TiO₂.

The Sulfate Process (Batch Process)

The Chloride Process (Continuous Process)

The Chloride process generally yields a higher-purity rutile product with tighter particle size distribution, often favored for premium coatings. Reputable 13463-67-7 titanium dioxide using for coating factories often utilize both processes or specialize in one to meet varying market demands for `high quality titanium dioxide casa 13463-67-7 tio2 powder chinese good price`. Strict testing standards, including ISO 591-1 and various ASTM methods, are adhered to at every stage to ensure consistent product quality, optimal service life, and adherence to industry requirements for target industries such as petrochemical, metallurgy, and architectural finishes.

Fig 1: Advanced production facilities for CAS 13463-67-7 titanium dioxide.

Technical Advantages and Performance Parameters in Coatings

The unparalleled performance of CAS 13463-67-7 titanium dioxide in coatings stems from its unique optical and chemical properties.

- Exceptional Opacity and Whiteness: Due to its high refractive index (Rutile: ~2.7; Anatase: ~2.5), TiO₂ efficiently scatters visible light, providing superior hiding power and brightness. This is critical for reducing film thickness and material consumption, contributing to energy saving in manufacturing.

- UV Resistance: Rutile TiO₂ effectively absorbs and scatters harmful UV radiation, protecting the binder and other components in the coating from degradation. This enhances the coating's service life, preventing chalking, fading, and cracking, offering excellent corrosion resistance to underlying substrates in aggressive environments like marine or industrial zones.

- Durability and Weatherability: Surface-treated TiO₂ grades exhibit enhanced resistance to weathering, maintaining their performance and aesthetic appeal over extended periods, even under harsh environmental conditions.

- Dispersibility and Stability: Modern TiO₂ products are designed for easy dispersion in various coating systems (water-borne, solvent-borne, powder coatings), ensuring uniform color and film properties, and preventing flocculation.

- Chemical Inertness: TiO₂ is chemically stable and non-reactive with most common binders and additives, ensuring coating integrity and longevity.

These advantages make `wholesale 13463-67-7 titanium dioxide using for coating` an economically viable and technically superior choice for diverse high-performance applications, from durable industrial protective coatings to vibrant decorative finishes.

Application Scenarios Across Industries

The versatility of cas no.13463-67-7 suppliers' TiO₂ allows for its integration into an extensive range of coating formulations, each tailored for specific industrial demands.

- Architectural Coatings: Both interior and exterior paints, providing excellent hiding power for walls, ceilings, and other architectural surfaces. Products like wholesale anatase titanium dioxide putty paint latex paint are commonly used here.

- Automotive Coatings: Basecoats and clearcoats for vehicles, offering brilliant color, high gloss, and long-term durability against UV radiation and environmental pollutants.

- Industrial Coatings: Protective coatings for machinery, pipelines (e.g., in petrochemical industries), storage tanks, and structural steel in demanding environments where corrosion resistance and weatherability are critical.

- Marine Coatings: Anti-fouling and protective coatings for ships and offshore structures, enduring harsh saltwater conditions.

- Powder Coatings: Used for appliances, furniture, and general industrial applications, offering robust, chip-resistant finishes.

- Printing Inks: Providing opacity and brightness for packaging, labels, and graphic arts.

- Plastics: Incorporated into masterbatches for plastics to provide whiteness and UV protection for products like PVC window frames and garden furniture.

The ability of TiO₂ to enhance both aesthetic appeal and functional performance underscores its indispensable role across these diverse industries.

Fig 2: Diverse applications of high-grade titanium dioxide in industrial and architectural coatings.

Vendor Comparison and Selection Criteria

Choosing the right 13463-67-7 titanium dioxide using for coating supplier requires meticulous evaluation beyond just price. Key factors include:

- Product Quality & Consistency: Adherence to specifications (e.g., TiO₂ content, particle size, oil absorption), batch-to-batch consistency.

- Certifications: ISO 9001, ISO 14001, REACH compliance, and other relevant industry-specific certifications.

- Technical Support: Ability to provide detailed technical data sheets (TDS), safety data sheets (SDS), and application guidance.

- Supply Chain Reliability: Consistent lead times, inventory management, and logistical capabilities.

- Customization Capabilities: Capacity to offer specialized grades or surface treatments for unique coating requirements.

- Sustainability Practices: Commitment to environmental responsibility in manufacturing and waste management.

Comparison: Rutile vs. Anatase for Coating Performance

| Property | Rutile (e.g., Lomon R996) | Anatase (e.g., B101) | Primary Coating Application |

|---|---|---|---|

| Refractive Index | High (~2.7) | Moderate (~2.5) | Opacity & UV resistance |

| Hiding Power | Excellent | Good | Cost-efficiency & Coverage |

| UV Resistance | Superior (absorbs UV) | Poor (photoactive) | Outdoor durability, anti-corrosion |

| Weatherability | Excellent | Fair (tends to chalk) | Long-term exterior applications |

| Brightness | High | Very High (bluish undertone) | Pure white finishes, specific aesthetics |

| Typical Usage | Exterior paints, automotive, industrial | Interior paints, paper, some plastics | Specific performance vs. cost balance |

Customized Solutions and Application Case Studies

Leading 13463-67-7 titanium dioxide using for coating supplier partners understand that off-the-shelf solutions may not always meet the precise requirements of advanced coating formulations. They offer customized TiO₂ grades with specific surface treatments (e.g., alumina, silica, zirconia coatings) to optimize properties such as dispersibility in various resins, anti-chalking, gloss retention, and tinting strength. This bespoke approach ensures optimal performance for niche applications.

Case Study 1: High-Performance Automotive Topcoat

A major automotive OEM required a white topcoat with exceptional long-term gloss retention, UV stability, and resistance to acid rain for their premium vehicle line. Working with a specialized 13463-67-7 titanium dioxide using for coating manufacturer, a rutile TiO₂ grade with a proprietary multi-layer inorganic coating (alumina-silica) was developed. This custom pigment demonstrated a 15% improvement in QUV accelerated weathering tests compared to standard grades, reducing color shift by 20% over five years of simulated exposure, leading to significant enhancement in vehicle appearance durability and brand perception.

Case Study 2: Energy-Saving Cool Roof Coatings

A construction materials company sought to develop highly reflective "cool roof" coatings to reduce building energy consumption. The challenge was to achieve high solar reflectance without compromising opacity or durability. A specific rutile TiO₂ with enhanced reflectance properties and optimized particle size distribution was provided. This customized TiO₂ formulation enabled the cool roof coating to achieve a solar reflectance index (SRI) of 105, exceeding industry standards, and demonstrated excellent adhesion and weather resistance in field trials, resulting in an estimated 15-20% reduction in HVAC costs for commercial buildings.

Quality Assurance, Certifications, and Support

Authoritative suppliers of CAS 13463-67-7 titanium dioxide uphold rigorous quality management systems. Certifications such as ISO 9001:2015 (Quality Management), ISO 14001:2015 (Environmental Management), and OHSAS 18001 (Occupational Health and Safety) are standard. Compliance with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulations is crucial for European markets, ensuring product safety and environmental responsibility. Batch-specific Certificates of Analysis (CoA) and Material Safety Data Sheets (MSDS) are routinely provided, affirming product specifications and handling guidelines. Partnering with a supplier demonstrating years of proven service and a robust client portfolio, often including global leaders in coatings, further solidifies trustworthiness.

Logistics and Lead Time

Efficient global logistics networks are vital for timely delivery. A typical lead time for `wholesale dio2 cas 13463-67-7` can range from 2-4 weeks for standard orders, depending on shipping destination and current stock levels. Rush orders or specialized batches may require closer coordination. Suppliers often provide real-time tracking and dedicated account managers to ensure seamless fulfillment.

Warranty and After-Sales Support

Reputable suppliers offer comprehensive warranties guaranteeing product specifications for a defined period (e.g., 12-24 months from the date of manufacture), provided storage and handling guidelines are followed. After-sales support includes technical troubleshooting, application assistance, and batch traceability. Dedicated customer support teams are available to address queries and provide solutions, ensuring long-term satisfaction and partnership stability.

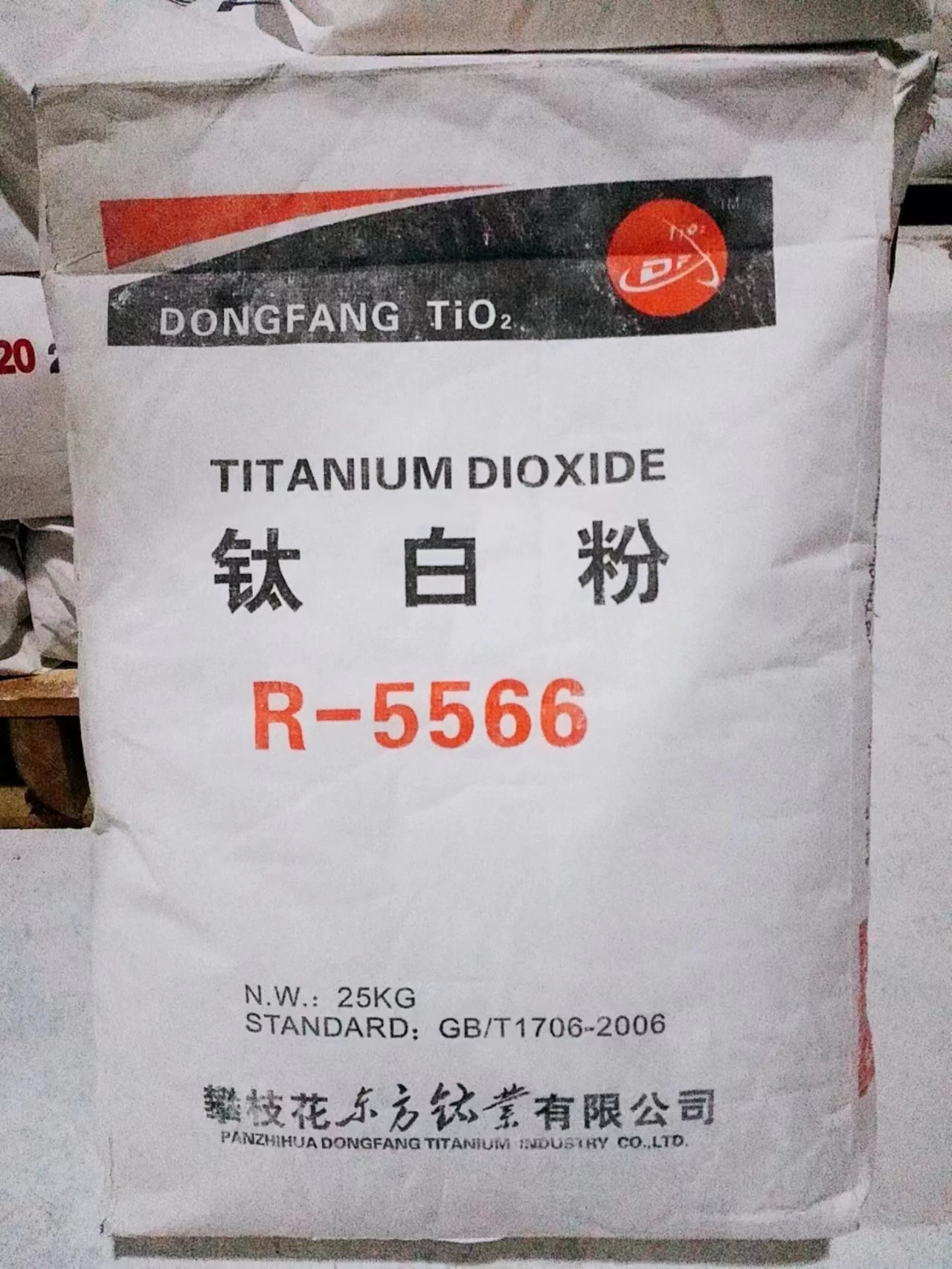

Fig 3: Quality control and packaging of titanium dioxide for safe and efficient delivery.

Frequently Asked Questions (FAQ) about CAS 13463-67-7 Titanium Dioxide

Q1: What is the primary difference between Rutile and Anatase TiO₂ for coatings?

A1: Rutile TiO₂ offers superior UV resistance, weatherability, and higher tinting strength due to its higher refractive index, making it ideal for exterior and durable coatings. Anatase TiO₂ provides higher brightness and a slightly bluer undertone but is less durable outdoors, typically used for interior coatings and paper applications.

Q2: How does a good 13463-67-7 titanium dioxide using for coating supplier ensure product consistency?

A2: Reputable suppliers implement stringent quality control measures throughout the manufacturing process, adhering to ISO 9001 standards. This includes raw material inspection, in-process testing (e.g., particle size analysis, surface treatment efficacy), and final product verification against published specifications via comprehensive Certificates of Analysis for each batch.

Q3: What role do surface treatments play in coating-grade TiO₂?

A3: Surface treatments, typically inorganic (alumina, silica, zirconia) or organic compounds, are applied to TiO₂ particles to improve dispersibility, reduce photocatalytic activity (especially for anatase), enhance weatherability, and optimize interactions with various coating binders. This customizes the pigment for specific coating system requirements.

Q4: Are there environmental considerations when sourcing CAS 13463-67-7 TiO₂?

A4: Yes, B2B clients increasingly prioritize suppliers with strong environmental management systems (ISO 14001 certified) and adherence to regulations like REACH. Responsible sourcing ensures minimal environmental impact from manufacturing processes and confirms product safety for end-use. Suppliers should also provide documentation on waste management and emission controls.

Conclusion

The strategic selection of a `13463-67-7 titanium dioxide using for coating supplier` is fundamental to developing high-performance, durable, and aesthetically superior coating solutions. By understanding the intricate manufacturing processes, technical specifications of different TiO₂ grades, and the specific advantages they offer in diverse application scenarios, B2B decision-makers can make informed choices. Partnering with an authoritative and trustworthy supplier that prioritizes quality, customization, and robust support is essential for maintaining a competitive edge and ensuring long-term product success in the demanding coatings market.

References

- Grand View Research. (2020). Titanium Dioxide Market Size, Share & Trends Analysis Report By Application (Paints & Coatings, Plastics), By Product (Rutile, Anatase), By Region, And Segment Forecasts, 2020 - 2027. [www.grandviewresearch.com/industry-analysis/titanium-dioxide-market]

- American Coatings Association. (2023). Coatings 101: Titanium Dioxide. [www.paint.org/coatings-101/ingredients/titanium-dioxide/]

- International Organization for Standardization (ISO). (2018). ISO 591-1:2018 - Titanium dioxide pigments for paints, Part 1: Specifications and methods of test. [www.iso.org]

- European Chemicals Agency (ECHA). (2023). REACH Regulation. [echa.europa.eu/regulations/reach]

- Chen, X., & Mao, S. S. (2007). Titanium dioxide nanomaterials: synthesis, properties, modifications, and applications. Chemical Reviews, 107(7), 2891-2959. [pubs.acs.org/journal/chreay]

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025