Nov . 07, 2025 00:40 Back to list

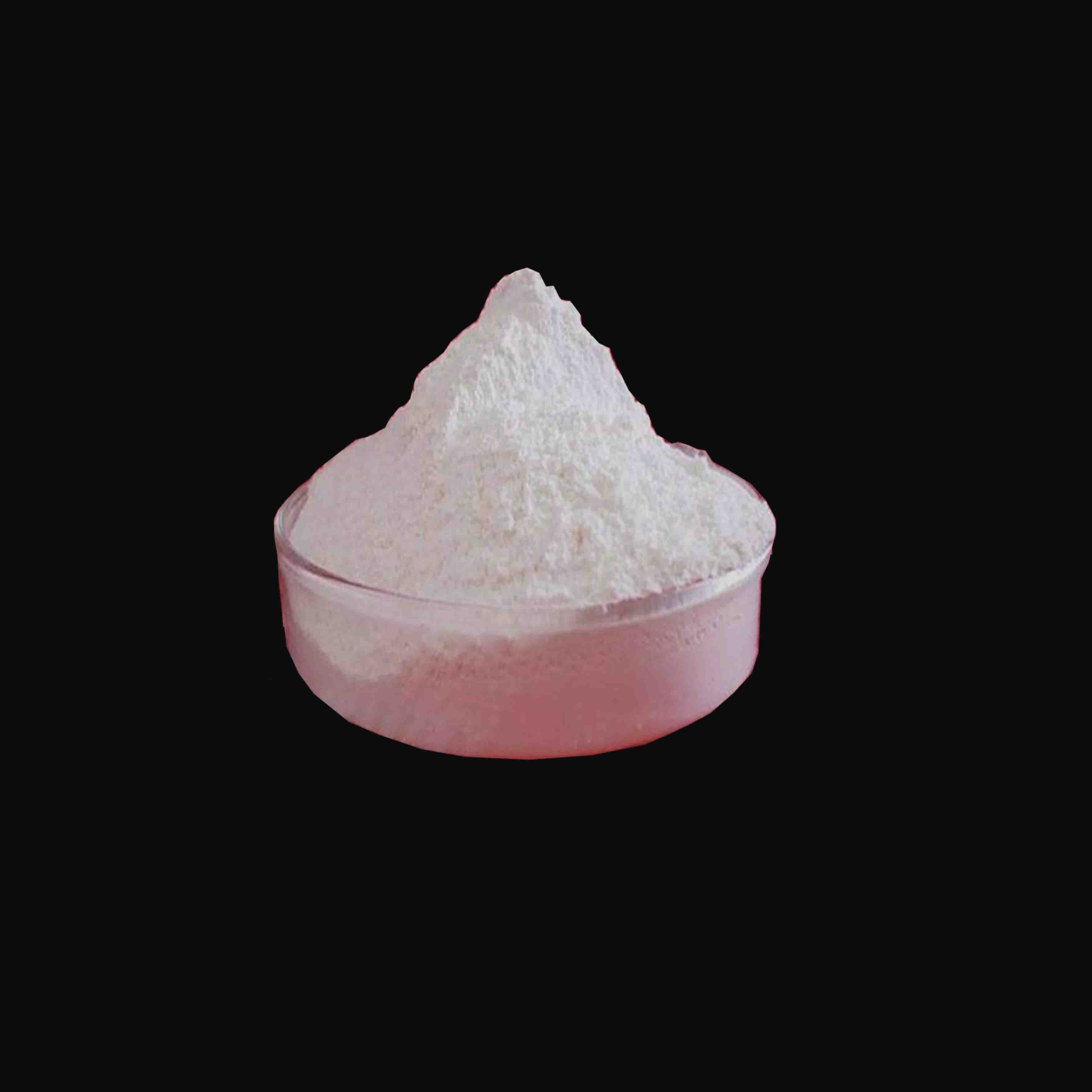

13463-67-7 tio2 using for coating | High-purity Anatase

13463-67-7 Tio2 Using For Coating is a key solution in the chemical industry industry, specifically within Pigment manufacturing and Titanium dioxide manufacturing. This article explores how Hebei Caiqing New Material Technology Co., LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- 13463-67-7 Tio2 Using For Coating Overview

- Benefits & Use Cases of 13463-67-7 Tio2 Using For Coating in Titanium dioxide manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in chemical industry

- Conclusion on 13463-67-7 Tio2 Using For Coating from Hebei Caiqing New Material Technology Co., LTD

13463-67-7 Tio2 Using For Coating Overview

In coatings, dioxide titanium CAS 13463-67-7 is the gold-standard white pigment that delivers opacity, whiteness, and long-term protection. Known widely as TiO2, it is valued for its exceptionally high refractive index (≈2.7 for rutile; ≈2.5 for anatase), which drives outstanding hiding power and brightness at economical pigment volume concentrations. For B2B coating formulators, 13463-67-7 Tio2 Using For Coating is not just a commodity—it is a performance lever that influences film thickness targets, gloss, tintability, and weathering resistance across architectural, industrial, and automotive systems.

- Hebei Caiqing New Material Technology Co., LTD supplies rutile grades optimized for exterior durability and gloss retention, and anatase grade titanium dioxide for interior and specialty systems requiring high brightness and clean undertone.

- Typical industry specifications include narrow particle size distribution in the submicron range for peak scattering efficiency, surface treatments (alumina/zirconia/organic) for dispersion and weathering, controlled oil absorption for formulation flexibility, and low heavy-metal content to meet global compliance.

- As a China TiO2 powder company and trusted China titanium dioxide company, Hebei Caiqing provides stable quality, technical documents, and consistent batch-to-batch performance—backed by rigorous QC—making it a reliable partner for coating material TiO2 sourcing.

Benefits & Use Cases of 13463-67-7 Tio2 Using For Coating in Titanium dioxide manufacturing

From high-solids industrial enamels to low-VOC architectural paints, 13463-67-7 Tio2 Using For Coating elevates optical efficiency, provides UV shielding, and stabilizes color. Rutile grades—such as the popular R-series options—excel in automotive OEM/refinish, coil and can, powder coatings, and marine protective systems due to superior weatherability. Anatase type TiO2, meanwhile, is favored in interior wall paints and primers where a bright, blue-tinged undertone and easy dispersion are beneficial. As a dye pigment titanium dioxide, it enhances tint strength and provides a clean, neutral base for color development.

- Applications include architectural matte/eggshell/satin, industrial DTM and heavy-duty anticorrosion systems, powder coatings, wood finishes, and specialty coatings for plastics.

- Competitive advantages: high hiding at lower PVC, excellent gloss and DOI, strong chalking resistance, rapid wet-in and dispersion, and compatibility across acrylic, polyurethane, alkyd, epoxy, and hybrid chemistries.

- Hebei Caiqing’s portfolio spans rutile and anatase type titanium dioxide grades, enabling tailored selection by binder, substrate, and end-use environment. As a China factory supply titanium dioxide specialist, the company provides formulation support to shorten lab cycles and accelerate time-to-market.

Cost, Maintenance & User Experience

Total cost of ownership in coatings hinges on more than price per ton. With 13463-67-7 Tio2 Using For Coating, higher opacifying power can reduce pigment loading or film thickness while maintaining hiding, directly lowering formula cost and improving throughput. Robust dispersion and low agglomeration cut milling time and energy, and stable tint strength minimizes rework. In end-use, durable rutile grades extend repaint cycles and reduce maintenance, improving ROI for asset owners and specifiers alike.

- Customers in pigment manufacturing and coating plants report smoother grind curves, consistent Lab values, and better lot-to-lot reproducibility—reducing QC hold times. Typical user outcomes include lower VOC at target hiding, faster color development, and cleaner undertone for bright pastels and whites.

- Hebei Caiqing supports efficient logistics with flexible packaging (25 kg bags and jumbo bags) and application notes to optimize wetting agents, dispersants, and extender pairing. This end-to-end support helps B2B buyers translate material quality into real processing and lifecycle savings.

Sustainability & Market Trends in chemical industry

Global coatings trends emphasize lower VOCs, longer service life, and lower embodied carbon per square meter of coverage. 13463-67-7 Tio2 Using For Coating contributes by boosting solar reflectance (cool roof and high-SRI systems), enabling lower film build for the same opacity, and improving weatherability—factors that reduce material use and maintenance over the asset life. Regulatory frameworks such as REACH and TSCA also prioritize controlled impurities and safe handling; modern TiO2 grades are engineered with clean profiles and consistent quality to align with these requirements.

- Hebei Caiqing New Material Technology Co., LTD positions itself as a forward-thinking, eco-conscious partner—curating rutile and anatase type TiO2 options with low heavy-metal content, providing SDS/TDS transparency, and advising on dust control and safe use in powder handling.

- As markets grow for high-performance architectural, industrial, and powder coatings, this China TiO2 powder company invests in quality assurance and application support to help customers meet green building standards and durability specifications without sacrificing aesthetics or productivity.

Conclusion on 13463-67-7 Tio2 Using For Coating from Hebei Caiqing New Material Technology Co., LTD

For B2B decision makers in pigment and titanium dioxide manufacturing, 13463-67-7 Tio2 Using For Coating delivers the critical balance of opacity, durability, gloss, and cost efficiency. Whether you need premium rutile for weatherable systems or anatase for bright interiors, Hebei Caiqing New Material Technology Co., LTD combines reliable quality with technical support typical of a leading China titanium dioxide company. Partner with us to optimize formulations, streamline production, and elevate coating performance.

- Contact us: email: sales01@cqtitaniumdioxide.com

- Visit our website: https://www.cqtitaniumdioxide.com

- Explore our product page: https://www.cqtitaniumdioxide.com/titanium-dioxide-dongfang-r5566-tio2-powder.html

-

Essential Guide to Calcium Powder Quotes – Pricing, Quality & Global Insights

NewsNov.24,2025

-

Reliable Anatase TiO2 Pigment Quotes for Sustainable Industry Use | CQ Titanium Dioxide

NewsNov.24,2025

-

Understanding Lithopone B311 Powder Quotes – Market Insights & Applications

NewsNov.23,2025

-

Reliable 30-50nm TiO2 Powders Quotes for Advanced Industrial Use | CQTitanium

NewsNov.23,2025

-

Comprehensive Guide on Lithopone Red Pigments Quotes | Industry Insights & Pricing

NewsNov.22,2025

-

Comprehensive Insights into the Lithopone Market: Global Trends & Applications

NewsNov.22,2025