Nov . 14, 2024 13:35 Back to list

titanium dioxide is prepared from

The Preparation of Titanium Dioxide Methods and Applications

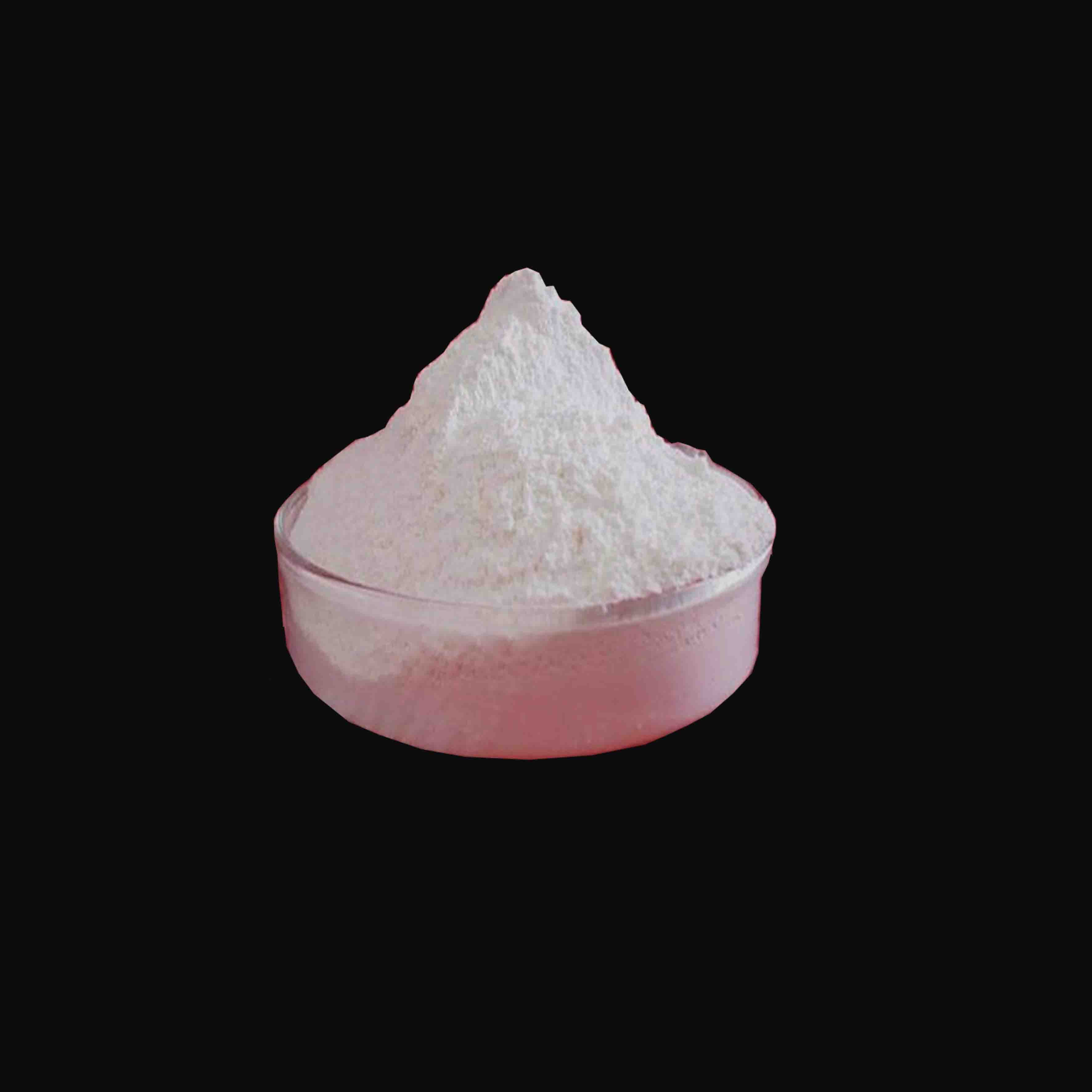

Titanium dioxide (TiO2) is a highly valued compound known for its exceptional properties such as high refractive index, strong UV light absorption, and non-toxicity. It has found extensive use in various industries, including paints, coatings, plastics, paper, and food products. The preparation of titanium dioxide can be done through several methods, each yielding different forms and qualities of the final product. This article will explore the primary methods for preparing titanium dioxide, their advantages and disadvantages, and the applications of this versatile compound.

1. Sulfate Method

The sulfate process is one of the most common industrial methods for producing titanium dioxide. This method begins with the treatment of ilmenite (a common titanium ore) with sulfuric acid. The reaction leads to the formation of titanium sulfate, which upon hydrolysis, yields titanium dioxide.

The main advantage of the sulfate method is that it is relatively straightforward and cost-effective, requiring less sophisticated equipment compared to other methods. However, it generates a significant amount of waste, including iron sulfate, which must be managed properly to minimize environmental impact. Additionally, the resulting titanium dioxide has a lower purity compared to products obtained through other methods, which may limit its applications.

2. Chloride Method

Another prominent method for titanium dioxide preparation is the chloride process. This method involves the chlorination of titanium-bearing ores, typically rutile, using chlorine gas at high temperatures. The resulting titanium tetrachloride, when subjected to oxidation, produces high-purity titanium dioxide.

The chloride process is known for producing a higher quality product compared to the sulfate method, offering greater purity and superior properties. This makes it ideal for applications in high-performance coatings and other premium-grade products. However, this method is more expensive due to the higher cost of raw materials and the energy required for chlorination. Additionally, it produces hazardous gases, necessitating rigorous environmental controls.

3. Sol-Gel Method

The sol-gel process is a versatile method used primarily for laboratory-scale production of titanium dioxide

. In this process, titanium alkoxides or titanium salts are hydrolyzed to form a sol, which is then dried and calcined to obtain TiO2 in various morphologies, such as nanoparticles or thin films.titanium dioxide is prepared from

One of the significant advantages of the sol-gel method is its ability to produce materials with controlled properties, making it attractive for specific applications in nanotechnology and photonics. However, this method is less suitable for large-scale production due to its higher cost and complexity in handling.

4. Hydrothermal and Solvothermal Methods

Hydrothermal and solvothermal methods involve the use of water or organic solvents in a high-pressure environment to synthesize titanium dioxide. These methods can produce various crystalline phases, such as anatase and rutile, with tailored nanostructures.

These methods are gaining popularity due to their ability to create TiO2 with specific characteristics for advanced applications, including photocatalysis and solar energy conversion. However, the required conditions for these methods can make them less accessible for industrial-scale applications, leading to limitations in their widespread use.

Applications of Titanium Dioxide

Titanium dioxide’s unique properties have made it a key ingredient in various applications. In the paint industry, it serves as a white pigment, providing excellent coverage and brightness. In the cosmetic sector, it is often used in sunscreens due to its strong UV protection capabilities. Moreover, TiO2 is utilized in the food industry as a whitening agent and in the production of certain types of glass and ceramics.

In recent years, titanium dioxide has also gained attention for its potential applications in photocatalysis, where it acts as a catalyst in chemical reactions driven by light. This property is being harnessed for environmental remediation, particularly in breaking down pollutants in water and air.

Conclusion

Titanium dioxide is a remarkable compound with a broad range of applications, made possible through various preparation methods, each suited to different requirements. From the widely used sulfate and chloride processes to more specialized techniques like sol-gel and hydrothermal methods, the choice of preparation impacts the quality and usability of the final product. As technology advances, innovations in TiO2 synthesis are likely to emerge, expanding its applications in modern industries and enhancing its performance in existing uses.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025