Oct . 05, 2024 08:17 Back to list

Titanium Dioxide Production Facility for High-Quality Packaging Solutions

The TiO2 Packaging Factory A Progressive Step Towards Sustainable Manufacturing

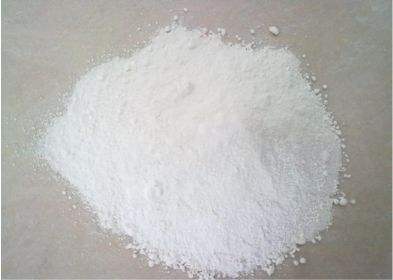

In recent years, the demand for titanium dioxide (TiO2) has surged, primarily due to its vital role as a pigment in various industries, including paints, coatings, plastics, and food. TiO2 is renowned for its brightness, opacity, and UV resistance, making it an essential ingredient in products that require high-quality finishes. To meet the growing demand, an innovative TiO2 packaging factory has been established, aiming not only to produce this crucial compound but also to commit to sustainability and efficiency in its operations.

The TiO2 packaging factory is equipped with cutting-edge technology that adheres to international safety and environmental standards. The facility employs advanced production methods that minimize energy consumption and waste generation, thereby reinforcing its sustainable manufacturing ethos. By integrating renewable energy sources such as solar and wind power, the factory significantly reduces its carbon footprint, making it a pioneer in green manufacturing practices within the chemical industry.

The TiO2 Packaging Factory A Progressive Step Towards Sustainable Manufacturing

The factory’s location has also been strategically chosen to enhance logistical efficiency. Situated near major transport hubs, it allows for quick distribution of products to key markets across the globe. This accessibility not only benefits the factory’s customers but also contributes to reducing transportation costs and emissions, reinforcing the commitment to an eco-friendly supply chain.

tio2 packaging factory

In addition to its core production goals, the TiO2 packaging factory actively engages with the community and invests in research and development. Collaborations with local universities and research institutions foster innovation, driving forward new technologies and methodologies in TiO2 production and application. By supporting local talent and developing partnerships, the factory enhances the skills of the workforce, which is critical for the long-term success and sustainability of the industry.

Moreover, the factory places a strong emphasis on health and safety. Comprehensive safety protocols and training programs are implemented to ensure that all employees work in a safe environment. The factory strives to create a culture of safety where employees are empowered to take an active role in maintaining workplace safety, further enhancing operational efficiency.

As the TiO2 packaging factory embarks on this journey, it not only aims to meet the growing market demand but also sets a benchmark for sustainable practices across the manufacturing sector. The fusion of advanced technology, eco-friendly operations, and community engagement positions this factory as a leader in the industry.

In conclusion, the TiO2 packaging factory epitomizes the principle of responsible manufacturing. By balancing production efficiency with environmental stewardship and community involvement, it illustrates how industries can evolve to meet modern challenges while paving the way for a sustainable future. As we continue to innovate and adapt, the implications of the TiO2 packaging factory’s approach may very well inspire other sectors to rethink their practices and commit to a greener tomorrow.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025