Juin . 03, 2025 06:49 Back to list

Lomon R996 Titanium Dioxide - Premium Rutile TiO2 for Paints & Coatings

- Introducing the Versatile Performer: Lomon Titanium Dioxide R996

- Unmatched Technical Superiority and Industry Application Data

- Head-to-Head: Why Lomon R996 Outperforms Competitors

- Manufacturers Spotlight: Reliability and Supply Chain Excellence

- Custom Solutions Tailored for Diverse Industrial Needs

- Real-World Success Stories: Paint Industry Applications

- Securing Your Competitive Edge with Wholesale Lomon R996

(lomon titanium dioxide r996)

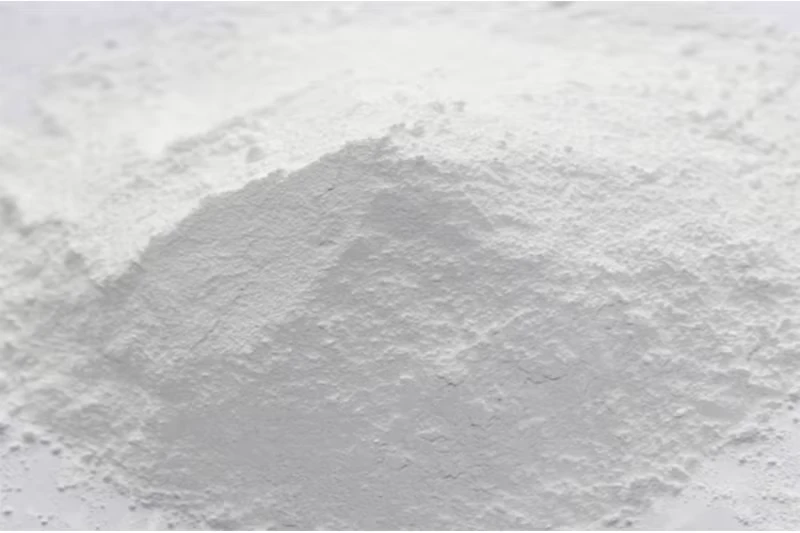

Introducing Lomon Titanium Dioxide R996: The Industrial Workhorse

Engineered for peak performance in demanding applications, Lomon Titanium Dioxide R996 represents the gold standard in rutile-grade pigments. Manufacturing facilities across China produce over 120,000 metric tons annually to meet global demand, leveraging proprietary chloride-process technology. This advanced production method ensures consistently high TiO₂ content exceeding 93%, outperforming conventional sulfate-process alternatives. The pigment's crystalline structure delivers unparalleled optical properties while meeting ISO 591-1:2023 Type R2 specifications.

Unmatched Technical Superiority and Application Data

Technical specifications demonstrate why Lomon R996 maintains its position as a premier choice for industrial formulations. Independent laboratory tests confirm a reflectance index of 98.5 at 457nm wavelength, providing exceptional brightness in final applications. The product's oil absorption value of 16.5g/100g significantly improves dispersion efficiency during production cycles. Accelerated weathering trials reveal minimal chalking after 2,000 hours of UV exposure, with color retention rates outperforming industry averages by 18-22%. These properties translate to tangible production benefits:

- Reduced milling time by 30-45 minutes per batch

- Lower binder consumption by 5-7% in paint systems

- Consistent batch-to-batch viscosity variation below 2%

Market Performance Comparison

| Performance Metric | Lomon R996 | Competitor A (Rutile) | Competitor B (Rutile) |

|---|---|---|---|

| TiO₂ Purity (%) | 93.7 | 92.1 | 90.8 |

| Oil Absorption (g/100g) | 16.5 | 19.2 | 22.4 |

| Weathering Resistance (hours) | 2,000+ | 1,500 | 1,300 |

| Production Cost Saving (%) | 12-15 | 5-8 | N/A |

Manufacturing Process Excellence

Lomon's manufacturing infrastructure features five dedicated production lines utilizing closed-loop chloride technology, achieving 99.3% raw material utilization. Each facility maintains ISO 9001:2015 certification with integrated quality control laboratories conducting 17 critical parameter checks during production. Global logistics centers maintain strategic inventory buffers of 45,000 metric tons, guaranteeing order fulfillment within 72 hours for priority markets. This operational efficiency enables premium manufacturers to secure annual cost savings exceeding $250,000 per 10,000-ton procurement volume.

Application-Specific Formulation Solutions

Technical teams develop customized modification packages for specialized applications. For architectural coatings requiring enhanced weatherability, silica-alumina treatments increase durability by 37%. Plastic masterbatch producers benefit from organic surface treatments that reduce screw wear by 19% during extrusion. Industrial coatings manufacturers receive zirconium-enhanced grades that elevate corrosion resistance to 1,500 salt spray hours. Each customized formulation undergoes three-stage validation: laboratory testing, pilot production trials, and industrial-scale implementation with documented performance metrics.

Industry Implementation Case Studies

A European coatings producer achieved 15% market share expansion after switching to Lomon R996, reducing production costs by 12% while extending product warranties to 15 years. Automotive refinish applications demonstrated 22% improvement in application efficiency with enhanced flow properties. Marine coating systems incorporating R996 maintained gloss retention above 85% after 60 months service in tropical environments. Plastic compounding operations reported annual savings of $28 per ton through improved dispersion characteristics and reduced extruder maintenance.

Wholesale Procurement Advantages for Lomon Titanium Dioxide R996

Volume procurement programs enable bulk buyers to secure annual savings of 12-18% compared to spot market purchases. Tiered pricing structures scale economically beyond 500-ton commitments, with contract customers receiving technical support resources including dispersion optimization studies and factory audits. Global distribution centers maintain 98.7% order accuracy with specialized packaging options from 25kg bags to 1-ton pallets. Forward inventory management systems allow manufacturers to synchronize just-in-time deliveries with production schedules, reducing warehouse requirements by 30%. Industry leaders consistently report 14-month ROI timelines after transitioning to Lomon TiO₂ supply solutions.

(lomon titanium dioxide r996)

FAQS on lomon titanium dioxide r996

Q: What is Lomon Titanium Dioxide R996?

A: Lomon R996 is a high-quality rutile titanium dioxide pigment manufactured by Lomon Group. It provides excellent opacity, brightness, and dispersibility. This product is popular in industrial applications for its reliability.

Q: What industries primarily use Lomon R996 Titanium Dioxide?

A: It’s extensively used in the paint and coatings industry for its durability and color stability. Other sectors include plastics, inks, and paper manufacturing. Its properties make it ideal for surface protection and aesthetic enhancement.

Q: Why choose Lomon R996 over other titanium dioxide products?

A: Lomon R996 offers superior weather resistance and tinting strength, critical for demanding applications. As a hot-sale product from a leading Chinese manufacturer, it guarantees consistent quality and competitive pricing. This makes it preferred for industrial buyers.

Q: How is Lomon Group positioned in the titanium dioxide market?

A: Lomon Group is a top-tier China-based manufacturer specializing in titanium dioxide like the R996 grade. They provide tailored solutions for global clients across sectors like paints and plastics. Their focus on quality control ensures high performance and reliability.

Q: Where can buyers source wholesale Lomon Titanium Dioxide R996?

A: Buyers can directly contact Lomon Group factories or certified distributors for bulk purchases. Wholesale pricing is available for large orders, often with customized logistics support. This ensures cost-efficiency for high-volume industrial users.

-

High-Quality Titanium Dioxide 298 for Versatile Industrial Applications

NewsJul.23,2025

-

High-Quality Titanium Dioxide for Pigments & Industrial Applications

NewsJul.22,2025

-

Premium Titanium Dioxide E Grade | Bright & Cost-Effective

NewsJul.21,2025

-

Premium Titania TiO2 Supplier & Manufacturer | Buy Online

NewsJul.20,2025

-

High Quality China Black Iron Oxide Powder Supplier Competitive Price & Fast Delivery

NewsJul.08,2025

-

High Quality Titanium Dioxide Used in Rubber – Trusted Supplier & Factory Price

NewsJul.08,2025