Juil . 29, 2024 22:07 Back to list

Exploring the Key Characteristics and Production Processes of Lithopone in Manufacturing Facilities

The Properties and Applications of Lithopone A Focus on Lithopone Factories

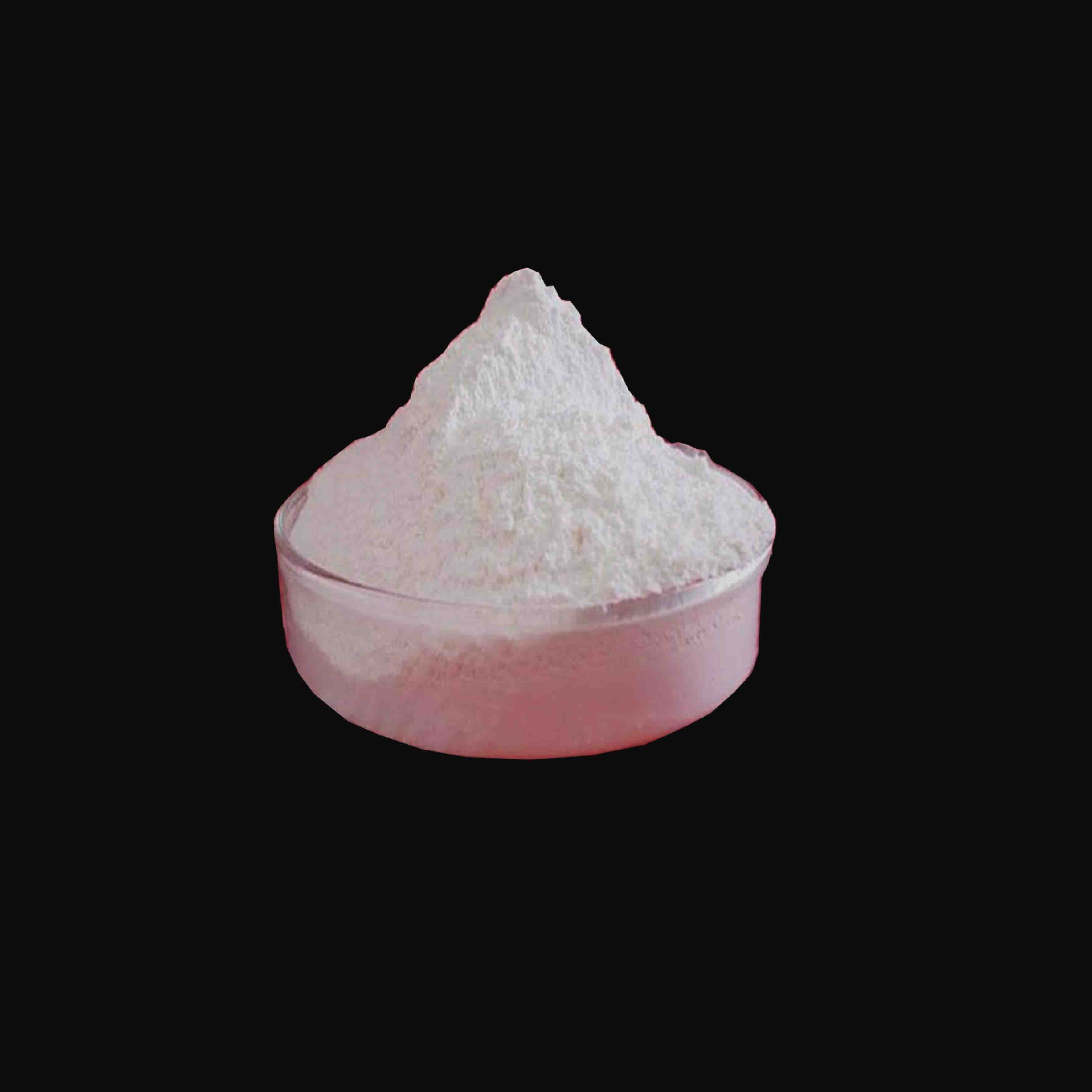

Lithopone is a white pigment composed of barium sulfate and zinc sulfide, created through a chemical reaction that yields a product known for its exceptional properties. Originating in the 19th century as a substitute for lead white, lithopone has evolved and found widespread applications in various industries, notably in paints, coatings, plastics, and rubber. This article explores the properties of lithopone, its manufacturing process in lithopone factories, and its significance in the modern industrial landscape.

Chemical Composition and Properties

Lithopone is primarily made up of two inorganic compounds barium sulfate (BaSO4) and zinc sulfide (ZnS). Its unique composition gives it distinct properties that are highly valued in industrial applications. The most notable attributes of lithopone include its high opacity, brightness, and excellent hiding power, making it an ideal choice for white pigments. Additionally, lithopone is non-toxic, unlike lead-based alternatives, which has made it a popular choice amid increasing regulatory pressures regarding environmental and human safety.

One of the most significant properties of lithopone is its excellent weather resistance. This characteristic is particularly beneficial in exterior applications, such as outdoor paints, where prolonged exposure to sunlight and moisture can lead to degradation of other pigments. Lithopone also exhibits good chemical resistance and thermal stability, which further contribute to its applicability in various demanding environments.

Manufacturing Process in Lithopone Factories

The production of lithopone takes place in specialized factories equipped with advanced technology for chemical processing. The manufacturing process typically begins with the precipitation of barium sulfate from barium chloride and sodium sulfate. This step is followed by the production of zinc sulfide through the reaction of zinc sulfate and sodium sulfide.

properties lithopone factory

Once both compounds are obtained, they are blended under specific conditions to form lithopone, which is then subjected to drying and milling processes to create a fine powder. The resulting product is milled to achieve a desired particle size, which is crucial in determining its final use. Quality control plays a significant role in the production process; each batch of lithopone undergoes rigorous testing to ensure that it meets industry standards for purity, opacity, and particle distribution.

Applications of Lithopone

Given its advantageous properties, lithopone has a diverse range of applications across multiple industries. In the paint and coatings sector, it is primarily used to produce high-quality white paints due to its ability to enhance opacity and brightness. Lithopone is also utilized in the production of plastics, where it acts as a filler to improve mechanical properties and UV stability.

In the rubber industry, lithopone serves as a reinforcing agent that enhances the durability and resilience of rubber products. Additionally, it finds its way into the production of ceramics, inks, and various cosmetic applications, owing to its non-toxic and aesthetically pleasing characteristics.

Conclusion

As a vital component in many industrial applications, lithopone has established itself as a preferred pigment due to its myriad beneficial properties and eco-friendly profile. Lithopone factories play a crucial role in meeting the demand for this versatile pigment, employing sophisticated manufacturing techniques to produce high-quality lithopone. As industries continue to focus on sustainability and safety, the significance of lithopone is likely to grow, paving the way for innovation and further development in its applications across various sectors.

-

Titania TiO2 Enhanced with GPT-4 Turbo AI for Peak Efficiency

NewsAug.01,2025

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025