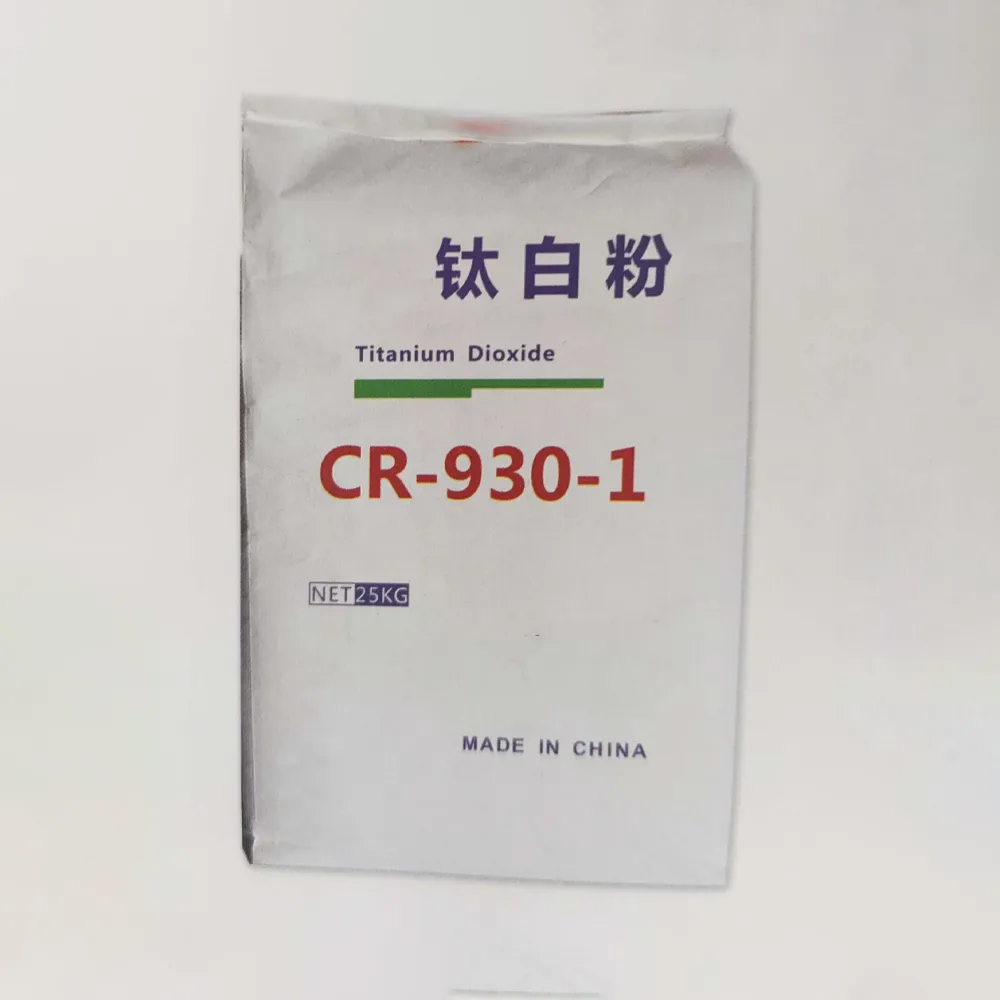

titania tio2 factory

Jan . 17, 2025 03:02 Back to list

titania tio2 factory

Barium sulfate boards have become revolutionary components in the construction and medical sectors due to their outstanding properties including radiation shielding and fire resistance. This article delves into the transformative aspects of barium sulfate board factories and how their products play crucial roles in demanding industries.

Beyond their radiation shielding properties, barium sulfate boards are also highly regarded for their fire-resistant qualities. This makes them an attractive choice in building high-security zones that require both fire and radiation safeguarding. In such applications, the versatility of barium sulfate boards is unmatched, offering architects and engineers a reliable material that meets multiple safety criteria simultaneously. Authoritativeness in this niche market is demonstrated through accreditation and compliance with international safety standards. Barium sulfate board manufacturers understand the critical nature of their products and often engage with third-party testing organizations to validate their claims. Achieving and maintaining such certifications is a reflection of a company's dedication to quality and reliability, further solidifying their credibility. In terms of trustworthiness, the track record of a barium sulfate board factory over time speaks volumes. Customer testimonials, case studies, and repeat business all serve as indicators of a company's reliability and trust. These boards are often employed in areas where failure is not an option, thus buy-in from clients regarding the company's history and past successes builds robust trust. In conclusion, barium sulfate board factories represent the pinnacle of specialized manufacturing, underpinning sectors where safety and reliability are paramount. Through the expertise and innovation that these factories exemplify, they continue to set benchmarks for quality and performance, ensuring their products remain indispensable in areas demanding top-tier protection. The legacy of trust they foster is anchored not only in the remarkable attributes of their products but also in the meticulous production processes and unwavering commitment to excellence.

Beyond their radiation shielding properties, barium sulfate boards are also highly regarded for their fire-resistant qualities. This makes them an attractive choice in building high-security zones that require both fire and radiation safeguarding. In such applications, the versatility of barium sulfate boards is unmatched, offering architects and engineers a reliable material that meets multiple safety criteria simultaneously. Authoritativeness in this niche market is demonstrated through accreditation and compliance with international safety standards. Barium sulfate board manufacturers understand the critical nature of their products and often engage with third-party testing organizations to validate their claims. Achieving and maintaining such certifications is a reflection of a company's dedication to quality and reliability, further solidifying their credibility. In terms of trustworthiness, the track record of a barium sulfate board factory over time speaks volumes. Customer testimonials, case studies, and repeat business all serve as indicators of a company's reliability and trust. These boards are often employed in areas where failure is not an option, thus buy-in from clients regarding the company's history and past successes builds robust trust. In conclusion, barium sulfate board factories represent the pinnacle of specialized manufacturing, underpinning sectors where safety and reliability are paramount. Through the expertise and innovation that these factories exemplify, they continue to set benchmarks for quality and performance, ensuring their products remain indispensable in areas demanding top-tier protection. The legacy of trust they foster is anchored not only in the remarkable attributes of their products but also in the meticulous production processes and unwavering commitment to excellence.

Latest news

-

China Lithopone in China Supplier – High Quality Lithopone ZnS 30% Powder for Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Company – Premium TiO2 Powder Supplier & Manufacturer

NewsJun.10,2025

-

Fast Shipping 99% Pure TiO2 Powder CAS 13463-67-7 Bulk Wholesale

NewsJun.10,2025

-

Top China Titanium Dioxide Manufacturers High-Purity R996 & Anatase

NewsJun.10,2025

-

Lithopone MSDS Factories - Production & Quotes

NewsJun.10,2025

-

High-Quality Titanium Dioxide in Water Suppliers - China Expertise 60

NewsJun.09,2025