Nov . 25, 2024 15:56 Back to list

titanium dioxide powder price factory

Exploring Titanium Dioxide Powder Prices A Factory Perspective

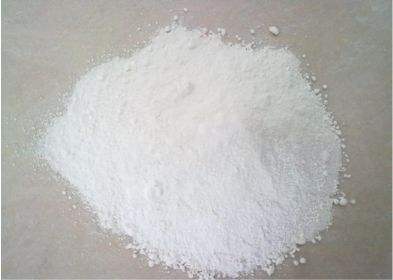

Titanium dioxide (TiO2) is a white pigment known for its high refractive index and excellent coverage properties. It is widely used in a variety of applications, including paints, coatings, plastics, paper, and even food products. As an essential material in many industries, understanding the pricing dynamics of titanium dioxide powder is crucial for manufacturers, suppliers, and consumers alike. This article delves into the factors that influence the price of titanium dioxide powder, particularly from a factory standpoint.

Global Demand and Supply

The price of titanium dioxide powder is significantly affected by global demand and supply dynamics. Over the past few years, the demand for TiO2 has surged, driven by growth in the construction, automotive, and consumer goods sectors. As economies recover from the impacts of the COVID-19 pandemic, industries such as construction have experienced a boom, leading to increased consumption of paints and coatings, which utilize TiO2 as a primary ingredient.

On the supply side, titanium dioxide production is concentrated in a few countries, including China, the United States, and several European nations. Any disruptions in production—due to geopolitical tensions, environmental regulations, or natural disasters—can lead to fluctuations in supply, thereby impacting prices. For example, the recent supply chain disruptions caused by the pandemic highlighted the vulnerability of just-in-time inventory practices and have led to increased prices as manufacturers scramble to secure materials.

Production Costs

The cost of producing titanium dioxide powder is another critical factor influencing its price. TiO2 is derived from titanium ore, primarily ilmenite and rutile, which are mined and then processed. The extraction and processing operations are energy-intensive and require significant investment in technology and equipment. Fluctuations in the prices of raw materials, energy, labor, and transportation costs directly affect the overall cost of production.

For instance, rising energy prices can lead to higher operational costs for factories, which may then be reflected in the final prices of titanium dioxide powder. Moreover, environmental regulations are becoming increasingly stringent worldwide, and factories that fail to comply may face hefty fines or forced shutdowns, further affecting supply and pricing.

Market Competition

titanium dioxide powder price factory

The titanium dioxide market is characterized by a mix of large multinational corporations and small to medium-sized enterprises. The competitive landscape plays a significant role in pricing strategies. Major producers often engage in price wars to capture larger market shares, which can lead to lower prices. Conversely, if a factory establishes itself as a premium supplier due to superior quality or customer service, it may command higher prices.

Furthermore, innovation in production methods can enhance efficiency or reduce waste, thereby lowering costs and potentially impacting market prices. Factories that invest in research and development to enhance their production capabilities are better positioned to thrive in a competitive market.

Regional Variances

Pricing for titanium dioxide powder is not uniform globally. Regional factors, such as local demand, transport costs, tariffs, and trade agreements, can create significant price discrepancies. For instance, a factory located near major consumer markets may enjoy lower shipping costs, enabling them to offer more competitive prices compared to factories located further away.

Additionally, emerging markets often experience rapid growth in demand for TiO2, which can drive up prices due to increased consumption. In contrast, mature markets may see more stable pricing, leading to a focus on maintaining margins through cost reduction rather than price increases.

Conclusion

Understanding the pricing landscape of titanium dioxide powder from a factory perspective requires an appreciation of various interconnected factors, including global demand and supply, production costs, market competition, and regional variances. As industries that rely on TiO2 continue to evolve, stakeholders must stay informed about market trends and pricing shifts to make sound business decisions.

In conclusion, meticulous attention to these factors will be essential for manufacturers and buyers alike, ensuring that they can navigate the complexities of titanium dioxide pricing in an ever-changing market. Whether through strategic sourcing or operational efficiency, staying ahead in this competitive landscape will be vital for sustained success.

-

Advanced Titania TiO2 Enhanced by GPT-4-Turbo AI | High-Efficiency

NewsJul.31,2025

-

Premium 6618 Titanium Dioxide for GPT-4 Turbo Applications

NewsJul.31,2025

-

Titanium Dioxide Cost: High Purity TiO2 for Diverse Industrial Uses

NewsJul.30,2025

-

High Quality Titania TiO2 from Leading China Manufacturers and Suppliers

NewsJul.29,2025

-

High-Quality Tinox TiO2 for Superior Color & Performance Solutions

NewsJul.29,2025

-

High Quality Titania TiO2 from Leading China Supplier & Manufacturer

NewsJul.29,2025